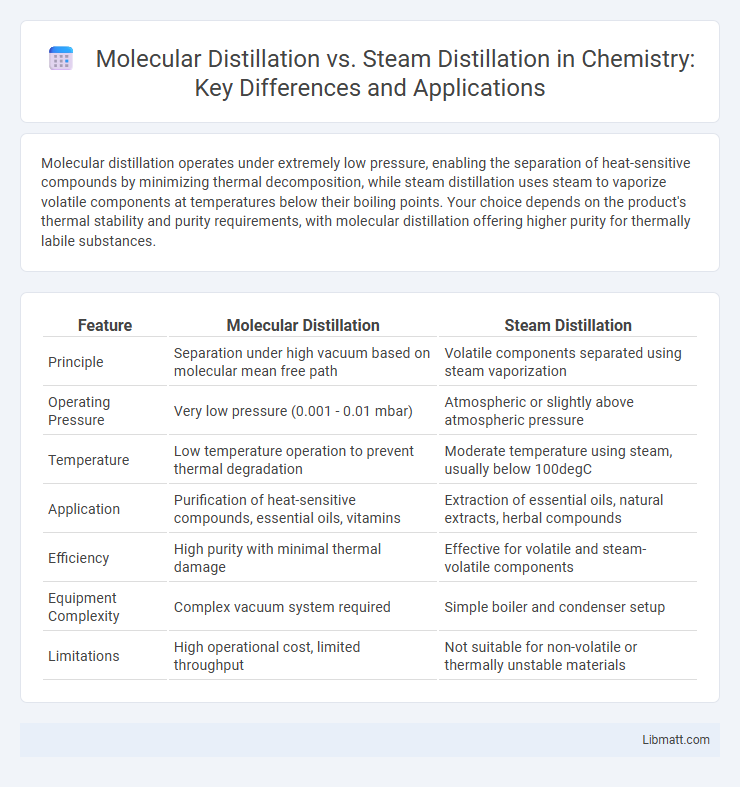

Molecular distillation operates under extremely low pressure, enabling the separation of heat-sensitive compounds by minimizing thermal decomposition, while steam distillation uses steam to vaporize volatile components at temperatures below their boiling points. Your choice depends on the product's thermal stability and purity requirements, with molecular distillation offering higher purity for thermally labile substances.

Table of Comparison

| Feature | Molecular Distillation | Steam Distillation |

|---|---|---|

| Principle | Separation under high vacuum based on molecular mean free path | Volatile components separated using steam vaporization |

| Operating Pressure | Very low pressure (0.001 - 0.01 mbar) | Atmospheric or slightly above atmospheric pressure |

| Temperature | Low temperature operation to prevent thermal degradation | Moderate temperature using steam, usually below 100degC |

| Application | Purification of heat-sensitive compounds, essential oils, vitamins | Extraction of essential oils, natural extracts, herbal compounds |

| Efficiency | High purity with minimal thermal damage | Effective for volatile and steam-volatile components |

| Equipment Complexity | Complex vacuum system required | Simple boiler and condenser setup |

| Limitations | High operational cost, limited throughput | Not suitable for non-volatile or thermally unstable materials |

Introduction to Distillation Methods

Molecular distillation is a low-temperature separation technique ideal for heat-sensitive compounds, utilizing a short path under high vacuum to minimize thermal degradation. Steam distillation involves passing steam through a mixture to vaporize components at temperatures below their boiling points, commonly used for extracting essential oils and volatile compounds. Both methods serve distinct purposes in chemical and pharmaceutical industries, with molecular distillation excelling in purifying high-boiling substances and steam distillation suited for temperature-sensitive plant materials.

Principles of Molecular Distillation

Molecular distillation operates on the principle of separating compounds by their volatility under high vacuum and low temperature, minimizing thermal degradation of heat-sensitive substances. This technique relies on the mean free path of molecules being comparable to the distance between the evaporating surface and the condensing surface, allowing efficient separation. You benefit from enhanced purity and preservation of delicate bioactive compounds compared to steam distillation, which uses vapor pressure and heat to extract components.

Fundamentals of Steam Distillation

Steam distillation operates on the principle that immiscible liquids, such as water and essential oils, lower the total vapor pressure, allowing the mixture to boil at a temperature below the boiling points of individual components. This technique is essential for isolating temperature-sensitive compounds without thermal decomposition. The process involves passing steam through the plant material, causing volatile compounds to vaporize and later condense into separate fractions for collection.

Key Differences Between Molecular and Steam Distillation

Molecular distillation operates at extremely low pressures, enabling the separation of heat-sensitive compounds by minimizing thermal decomposition, whereas steam distillation uses steam to vaporize components at temperatures below their boiling points in atmospheric or slightly reduced pressure. Molecular distillation offers higher purity and yield for fragile substances like vitamins, essential oils, and cannabinoids, while steam distillation is commonly applied for extracting essential oils from plant materials. The precise control over pressure and temperature in molecular distillation allows for efficient separation of high-boiling-point mixtures, contrasting with steam distillation's reliance on steam to facilitate distillation at lower, more moderate conditions.

Applications of Molecular Distillation

Molecular distillation is widely used in industries requiring the purification of heat-sensitive compounds, such as pharmaceuticals, essential oils, and high-value bioactive lipids. Unlike steam distillation, which is ideal for extracting volatile oils from plant materials, molecular distillation excels in separating substances with very high boiling points or minimal thermal degradation. Your choice of molecular distillation enables precise fractionation and concentration of delicate molecules, ensuring product purity and efficacy in complex formulations.

Common Uses of Steam Distillation

Steam distillation is primarily used for extracting essential oils from delicate plant materials, such as flowers, herbs, and spices, without degrading their aromatic compounds. This method is also employed in the pharmaceutical and cosmetic industries to isolate heat-sensitive compounds and purify natural fragrances. In contrast to molecular distillation, steam distillation operates at lower temperatures, preserving the integrity of the extracted substances.

Advantages of Molecular Distillation

Molecular distillation offers significant advantages over steam distillation due to its ability to operate at much lower temperatures, preserving thermally sensitive compounds and preventing their degradation. It provides higher purity and better separation efficiency for heat-sensitive substances, often used in pharmaceuticals, essential oils, and food industries. The short residence time and vacuum environment minimize oxidation and contamination, resulting in superior product quality compared to steam distillation.

Benefits of Steam Distillation

Steam distillation offers significant benefits for extracting heat-sensitive compounds, as it operates at lower temperatures than molecular distillation, preserving delicate aromas and active ingredients. Its efficiency in separating volatile components from non-volatile residues makes it ideal for essential oil production and herbal extractions. By choosing steam distillation, you ensure a cost-effective and scalable process suitable for a wide range of botanical materials.

Limitations and Challenges of Each Method

Molecular distillation faces limitations such as high equipment costs, sensitivity to temperature, and low throughput, making it less suitable for large-scale operations. Steam distillation encounters challenges including the potential degradation of heat-sensitive compounds and the difficulty in separating components with similar boiling points. Both methods require careful optimization to balance efficiency, product quality, and operational complexity in industrial applications.

Choosing the Right Distillation Technique

Molecular distillation is ideal for separating heat-sensitive compounds and achieving high purity through low-pressure and low-temperature conditions, whereas steam distillation is more suitable for extracting volatile, water-immiscible components from plant materials. The choice depends on factors such as the thermal stability of the substance, desired purity level, and scale of operation; molecular distillation offers precision for complex mixtures, while steam distillation is cost-effective for bulk extraction of essential oils. Evaluating the chemical properties and processing goals ensures selecting the distillation technique that optimizes yield and product quality.

Molecular distillation vs steam distillation Infographic

libmatt.com

libmatt.com