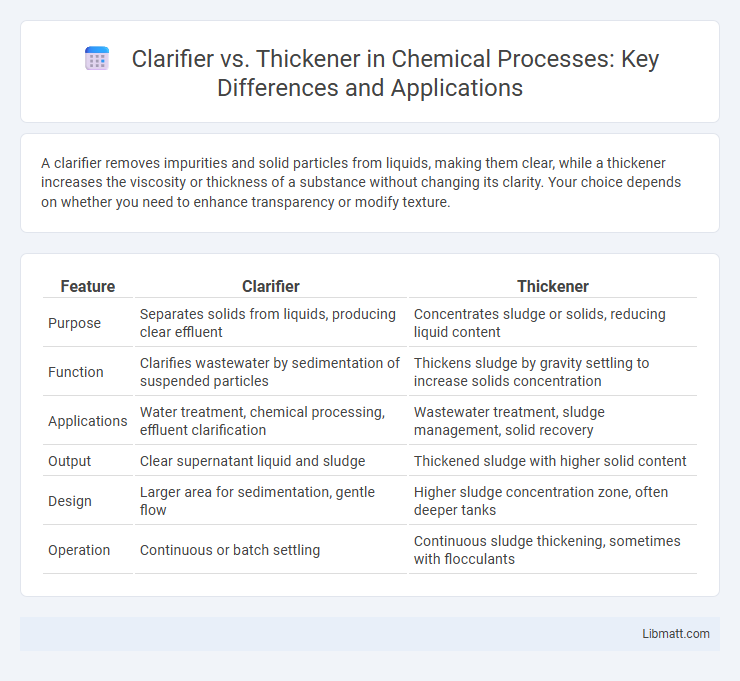

A clarifier removes impurities and solid particles from liquids, making them clear, while a thickener increases the viscosity or thickness of a substance without changing its clarity. Your choice depends on whether you need to enhance transparency or modify texture.

Table of Comparison

| Feature | Clarifier | Thickener |

|---|---|---|

| Purpose | Separates solids from liquids, producing clear effluent | Concentrates sludge or solids, reducing liquid content |

| Function | Clarifies wastewater by sedimentation of suspended particles | Thickens sludge by gravity settling to increase solids concentration |

| Applications | Water treatment, chemical processing, effluent clarification | Wastewater treatment, sludge management, solid recovery |

| Output | Clear supernatant liquid and sludge | Thickened sludge with higher solid content |

| Design | Larger area for sedimentation, gentle flow | Higher sludge concentration zone, often deeper tanks |

| Operation | Continuous or batch settling | Continuous sludge thickening, sometimes with flocculants |

Introduction to Clarifiers and Thickeners

Clarifiers and thickeners are essential equipment used in water and wastewater treatment to separate solids from liquids. Clarifiers primarily promote the settlement of suspended solids to produce clearer effluent, while thickeners concentrate solids by removing water to form denser sludge. Both devices optimize solid-liquid separation but serve distinct roles based on operational goals and process requirements.

Clarifiers: Definition and Purpose

Clarifiers are specialized equipment used in water and wastewater treatment to separate suspended solids from liquids through sedimentation. Their primary purpose is to reduce turbidity by allowing heavier particles to settle at the bottom, resulting in a clearer, cleaner effluent. Clarifiers enhance the efficiency of subsequent treatment processes by producing low-solid, clarified liquid suitable for discharge or further processing.

Thickeners: Definition and Function

Thickeners are specialized additives used to increase the viscosity of liquids without substantially altering their other properties. Their primary function is to improve texture, stability, and consistency in various industrial and food applications. Your formulation benefits from thickeners by enhancing flow control and preventing separation in products like sauces, cosmetics, and wastewater treatment.

Key Differences Between Clarifiers and Thickeners

Clarifiers and thickeners are both essential in solid-liquid separation but serve different functions: clarifiers primarily separate suspended solids to produce a clear effluent, while thickeners concentrate solids by increasing the sludge density. Clarifiers focus on removing lighter solids from water, often in wastewater treatment, whereas thickeners handle higher solids loads to reduce the volume before disposal or further processing. Design differences include clarifiers having longer residence times and larger surface areas for sedimentation, whereas thickeners are built for compaction and sludge volume reduction through compression and gravity settling.

Operating Principles of Clarifiers

Clarifiers operate by allowing suspended solids and particles to settle through gravity separation in a quiescent environment, facilitating the removal of sludge from the bottom and clarified liquid from the top. The design incorporates features such as sludge scraping mechanisms and adjustable weirs to optimize solids removal efficiency and maintain consistent overflow rates. This gravity settling process distinguishes clarifiers from thickeners, which primarily focus on increasing solids concentration by thickening sludge before disposal or further processing.

Operating Mechanisms of Thickeners

Thickeners operate by promoting the sedimentation of solids through controlled agitation and slow rotation, allowing fine particles to settle and concentrate sludge at the bottom while clear water overflows. The flocculant addition enhances particle aggregation, accelerating the settling process and improving sludge compaction. Unlike clarifiers, thickeners maintain a high solids concentration, optimizing space and efficiency in wastewater treatment and mineral processing.

Applications of Clarifiers in Industry

Clarifiers are widely used in wastewater treatment plants to remove suspended solids from industrial effluents, improving water quality before discharge or reuse. In industries like mining, food processing, and chemical manufacturing, clarifiers help separate solids from liquids, enhancing process efficiency and reducing environmental impact. Your facility can benefit from clarifiers by achieving regulatory compliance and optimizing resource recovery in various production processes.

Industrial Uses of Thickeners

Thickeners are essential in industries such as mining, wastewater treatment, and chemical processing for solid-liquid separation and slurry concentration. Unlike clarifiers that primarily settle suspended solids, thickeners increase the density of solids, reducing volume and improving resource recovery efficiency. Your industrial processes benefit from the enhanced material handling and reduced disposal costs provided by these vessels.

Factors Influencing Selection: Clarifier or Thickener

Factors influencing selection between a clarifier and thickener include the desired separation efficiency, solids concentration, and water recovery rate. Clarifiers are chosen for effective removal of suspended solids with moderate sludge concentration, while thickeners are preferred when maximizing solids concentration and reducing sludge volume is essential. Your process requirements, such as feed characteristics and space constraints, play a critical role in determining the optimal equipment.

Maintenance, Efficiency, and Troubleshooting

Clarifiers require regular sludge removal and baffle cleaning to maintain optimal sedimentation efficiency, while thickeners need frequent rake inspections and polymer dosing adjustments to ensure consistent solids concentration. Efficiency in clarifiers hinges on controlling flow rates and preventing short-circuiting, whereas thickeners depend on proper floc formation and uniform feed distribution for effective thickening. Troubleshooting clarifier issues often involves addressing sludge blanket disturbances and scum removal, while thickener challenges typically include rake torque problems and poor underflow density control.

Clarifier vs thickener Infographic

libmatt.com

libmatt.com