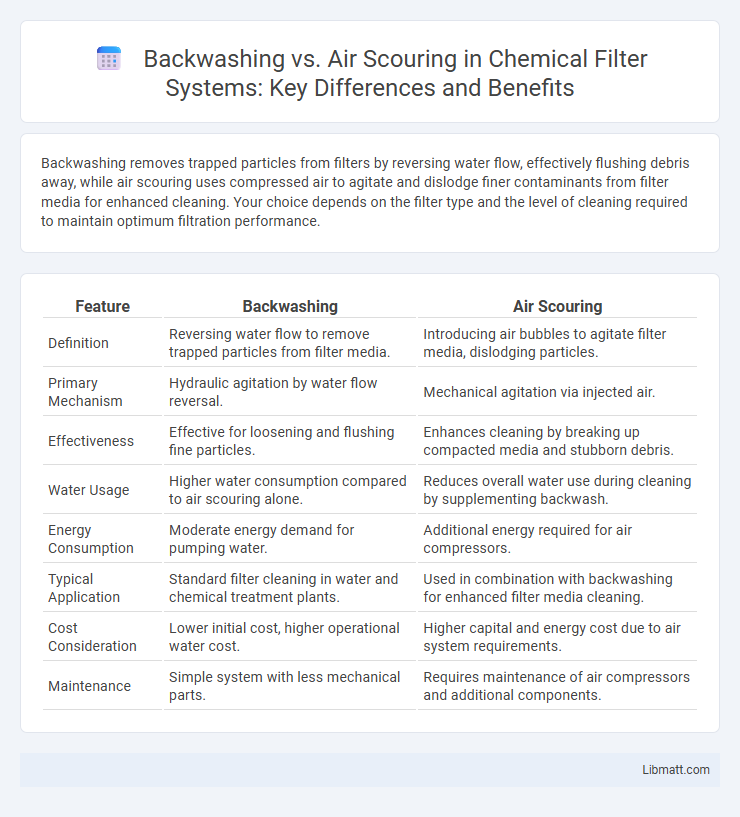

Backwashing removes trapped particles from filters by reversing water flow, effectively flushing debris away, while air scouring uses compressed air to agitate and dislodge finer contaminants from filter media for enhanced cleaning. Your choice depends on the filter type and the level of cleaning required to maintain optimum filtration performance.

Table of Comparison

| Feature | Backwashing | Air Scouring |

|---|---|---|

| Definition | Reversing water flow to remove trapped particles from filter media. | Introducing air bubbles to agitate filter media, dislodging particles. |

| Primary Mechanism | Hydraulic agitation by water flow reversal. | Mechanical agitation via injected air. |

| Effectiveness | Effective for loosening and flushing fine particles. | Enhances cleaning by breaking up compacted media and stubborn debris. |

| Water Usage | Higher water consumption compared to air scouring alone. | Reduces overall water use during cleaning by supplementing backwash. |

| Energy Consumption | Moderate energy demand for pumping water. | Additional energy required for air compressors. |

| Typical Application | Standard filter cleaning in water and chemical treatment plants. | Used in combination with backwashing for enhanced filter media cleaning. |

| Cost Consideration | Lower initial cost, higher operational water cost. | Higher capital and energy cost due to air system requirements. |

| Maintenance | Simple system with less mechanical parts. | Requires maintenance of air compressors and additional components. |

Introduction to Filter Cleaning Methods

Backwashing and air scouring are essential filter cleaning methods designed to maintain optimal filtration efficiency in water treatment systems. Backwashing involves reversing the flow of water through the filter media to dislodge trapped particles, while air scouring uses compressed air to agitate the filter bed, enhancing the removal of stubborn contaminants. Both techniques extend filter lifespan, improve water quality, and reduce operational downtime by preventing clogging and media compaction.

What is Backwashing in Water Treatment?

Backwashing in water treatment is a cleaning process used to remove trapped particles and contaminants from filter media by reversing the flow of water through the filter bed. This method flushes out accumulated debris, restoring filter efficiency and maintaining water quality. Compared to air scouring, backwashing relies solely on water flow, making it effective for dislodging fine particles in granular media filters.

Understanding Air Scouring in Filtration Systems

Air scouring in filtration systems enhances filter media cleaning by injecting compressed air to agitate and dislodge trapped particles more effectively than backwashing alone. This method improves filtration efficiency and extends filter lifespan by preventing media compaction and channeling. Understanding air scouring helps you optimize the operation and maintenance of your filtration system for superior water quality.

Key Differences: Backwashing vs Air Scouring

Backwashing uses water flow reversal to remove trapped particles from filter media, effectively rinsing the filter bed to restore filtration capacity, while air scouring employs compressed air agitation to dislodge impurities by creating turbulence within the filter. Your choice between backwashing and air scouring depends on filter type and contaminant characteristics, as air scouring enhances cleaning efficiency in granular filters by breaking up compacted solids that backwashing alone may not remove. Key differences include the mechanism of media cleaning--hydraulic flushing versus pneumatic agitation--and the operational requirements such as water and air consumption.

Efficiency and Effectiveness of Each Method

Backwashing efficiently removes accumulated particles by reversing water flow through filters, effectively restoring filter capacity with moderate water use and typically lower operational costs. Air scouring enhances cleaning efficiency by injecting compressed air to agitate and dislodge trapped solids more thoroughly, resulting in higher cleanliness levels but increased energy consumption and maintenance demands. Combining both methods often achieves optimal filter performance, balancing thorough contaminant removal with operational efficiency.

Operational Costs and Resource Requirements

Backwashing filters typically incur higher operational costs due to increased water consumption and energy usage required to reverse flow and remove captured debris. Air scouring reduces resource requirements by using compressed air to agitate the filter media, lowering water usage and often decreasing cycle frequency, which can lead to cost savings over time. Your choice between these methods will impact maintenance expenses and resource efficiency depending on the filtration system's scale and application.

Impact on Filter Media Longevity

Backwashing typically extends filter media longevity by gently removing accumulated contaminants without causing significant abrasion, preserving the structural integrity of the media. Air scouring, while highly effective at dislodging trapped particles through vigorous agitation, can accelerate media wear and breakdown over time due to increased mechanical stress. Optimizing the balance between backwashing frequency and periodic air scouring is essential to maintain filter efficiency while minimizing premature media degradation.

Applications: When to Use Backwashing or Air Scouring

Backwashing is ideal for removing accumulated solids from granular filters in water treatment systems, commonly used in municipal and industrial applications where frequent filter cleaning is essential. Air scouring enhances filter performance by injecting air to agitate and dislodge stubborn particles, making it suitable for media filters with compacted debris or organic matter. Your choice depends on the filter type and contamination level, with backwashing preferred for routine maintenance and air scouring employed for thorough cleaning in heavily fouled systems.

Environmental Considerations and Sustainability

Backwashing filters consume significant volumes of water, raising concerns about water wastage and effluent discharge impacting local ecosystems. Air scouring enhances filter cleaning efficiency, reducing water use and enabling longer filter run times, which supports sustainable water treatment operations. Implementing air scouring can decrease chemical usage and energy consumption, contributing to lower environmental footprints in filtration systems.

Choosing the Right Filter Cleaning Method

Selecting the right filter cleaning method depends on the type of filter media and the level of fouling. Backwashing is effective for removing loose particles and restoring filter flow in granular media filters, while air scouring enhances cleaning efficiency by agitating the filter bed and breaking up trapped contaminants. Your choice should consider operational costs, water quality, and how thoroughly each method can maintain optimal filtration performance.

Backwashing vs air scouring (filters) Infographic

libmatt.com

libmatt.com