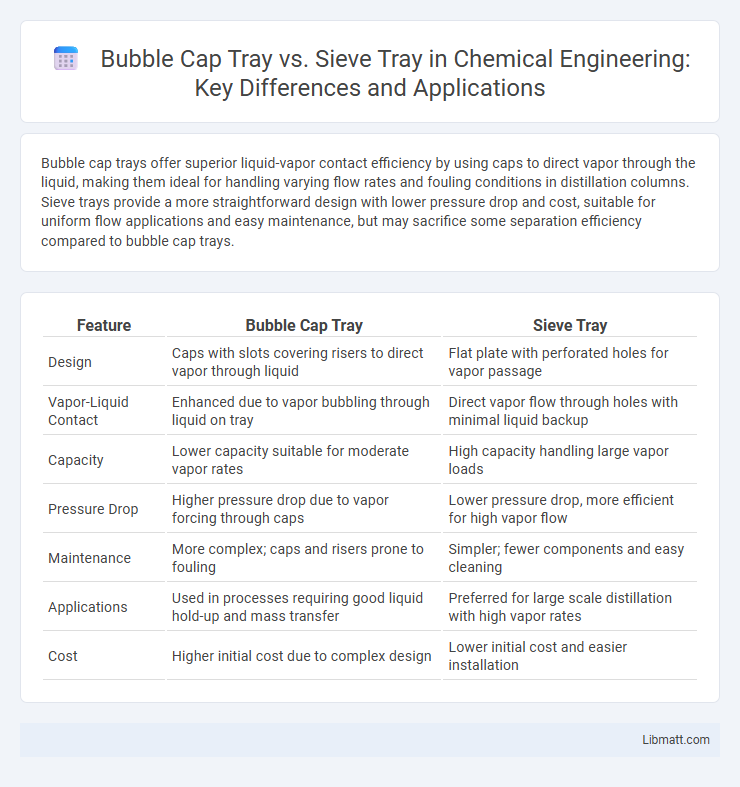

Bubble cap trays offer superior liquid-vapor contact efficiency by using caps to direct vapor through the liquid, making them ideal for handling varying flow rates and fouling conditions in distillation columns. Sieve trays provide a more straightforward design with lower pressure drop and cost, suitable for uniform flow applications and easy maintenance, but may sacrifice some separation efficiency compared to bubble cap trays.

Table of Comparison

| Feature | Bubble Cap Tray | Sieve Tray |

|---|---|---|

| Design | Caps with slots covering risers to direct vapor through liquid | Flat plate with perforated holes for vapor passage |

| Vapor-Liquid Contact | Enhanced due to vapor bubbling through liquid on tray | Direct vapor flow through holes with minimal liquid backup |

| Capacity | Lower capacity suitable for moderate vapor rates | High capacity handling large vapor loads |

| Pressure Drop | Higher pressure drop due to vapor forcing through caps | Lower pressure drop, more efficient for high vapor flow |

| Maintenance | More complex; caps and risers prone to fouling | Simpler; fewer components and easy cleaning |

| Applications | Used in processes requiring good liquid hold-up and mass transfer | Preferred for large scale distillation with high vapor rates |

| Cost | Higher initial cost due to complex design | Lower initial cost and easier installation |

Introduction to Bubble Cap and Sieve Trays

Bubble cap trays feature caps that direct vapor through liquid on the tray, enhancing contact efficiency in distillation columns. Sieve trays consist of perforated plates allowing vapor to pass through holes, promoting vapor-liquid interaction with lower pressure drop. Your choice depends on factors like capacity, operating pressure, and mass transfer efficiency.

Basic Working Principles

Bubble cap trays function by allowing vapor to pass through caps and bubble up through a liquid layer, promoting efficient mass transfer through intimate vapor-liquid contact. Sieve trays feature perforated plates where vapor rises through holes directly into a liquid pool on the tray, facilitating phase interaction though with less liquid hold-up than bubble cap trays. Selecting the right tray type impacts your distillation column's efficiency and operational flexibility based on factors like vapor load and liquid capacity.

Design and Structural Differences

Bubble cap trays feature a fixed design with caps covering risers that allow vapor to pass through while forcing liquid downwards, creating efficient mass transfer with minimal entrainment. Sieve trays consist of perforated plates where vapor flows directly through holes, offering a simpler, lighter structure but potentially higher entrainment and pressure drop. Your choice between bubble cap and sieve trays depends on operational parameters, including vapor-liquid traffic and fouling tendencies, influencing tray design and durability.

Efficiency and Performance Comparison

Bubble cap trays provide superior vapor-liquid contact efficiency in distillation columns due to their design, enabling better handling of a wide range of flow rates and minimizing entrainment. Sieve trays, while simpler and less costly, offer high capacity and reduced pressure drop but may underperform in terms of mass transfer efficiency, especially at lower vapor velocities. Overall, bubble cap trays excel in performance for processes requiring precise separation, whereas sieve trays are preferred for applications prioritizing throughput and cost-effectiveness.

Pressure Drop Characteristics

Bubble cap trays exhibit lower pressure drop compared to sieve trays due to their design, which allows vapor to pass through liquid-filled caps, minimizing resistance. Sieve trays have higher pressure drop as vapor must force through perforations directly, creating increased turbulence and energy loss. This difference impacts column efficiency and operating costs, with bubble cap trays preferred in low-pressure drop applications.

Operational Flexibility

Bubble cap trays offer greater operational flexibility by efficiently handling a wide range of vapor and liquid flow rates with minimal performance loss. Sieve trays, while simpler in design and lower in cost, typically require more precise flow conditions to maintain optimal efficiency. Your choice between the two should consider the specific variability of your process and the need for adaptable tray operation.

Fouling and Maintenance Considerations

Bubble cap trays typically experience less fouling due to their enclosed design, which limits the accumulation of debris and reduces contamination risks, making maintenance less frequent and more straightforward. Sieve trays, with open perforations, are more susceptible to clogging from particulates, requiring more regular cleaning and inspections to maintain optimal performance. Your choice between the two trays should factor in the fouling potential of your feed stream and the ease of maintenance to ensure efficient operation and reduced downtime.

Cost Implications

Bubble cap trays generally have higher manufacturing and maintenance costs due to their more complex design and precision components, while sieve trays offer a simpler construction that reduces initial investment and upkeep expenses. Your choice between the two affects overall operational efficiency, with sieve trays often favored in large-scale distillation columns where cost-efficiency is crucial. Selecting the right tray type impacts budget allocation and long-term economic performance in separation processes.

Typical Applications in Industry

Bubble cap trays are highly effective in distillation and absorption processes involving liquids with low vapor rates and high liquid loads, commonly used in chemical plants, petrochemical refineries, and pharmaceutical industries for precise vapor-liquid contact. Sieve trays, favored for their simplicity and cost-effectiveness, are extensively applied in large-scale distillation and gas absorption units within oil refineries, natural gas processing, and air separation plants. Industrial sectors select bubble cap trays for superior vapor-liquid mixing under challenging operating conditions, while sieve trays dominate where high capacity and lower maintenance are prioritized.

Choosing the Right Tray for Your Process

Choosing the right tray for your process depends on factors like liquid and vapor flow rates, pressure drop, and separation efficiency. Bubble cap trays offer reliable performance under varying flow conditions and handle fouling better, while sieve trays provide higher capacity and lower pressure drops in clean systems. Your choice impacts overall distillation column efficiency and operational costs, making it essential to match tray type with your specific process requirements.

Bubble cap tray vs sieve tray Infographic

libmatt.com

libmatt.com