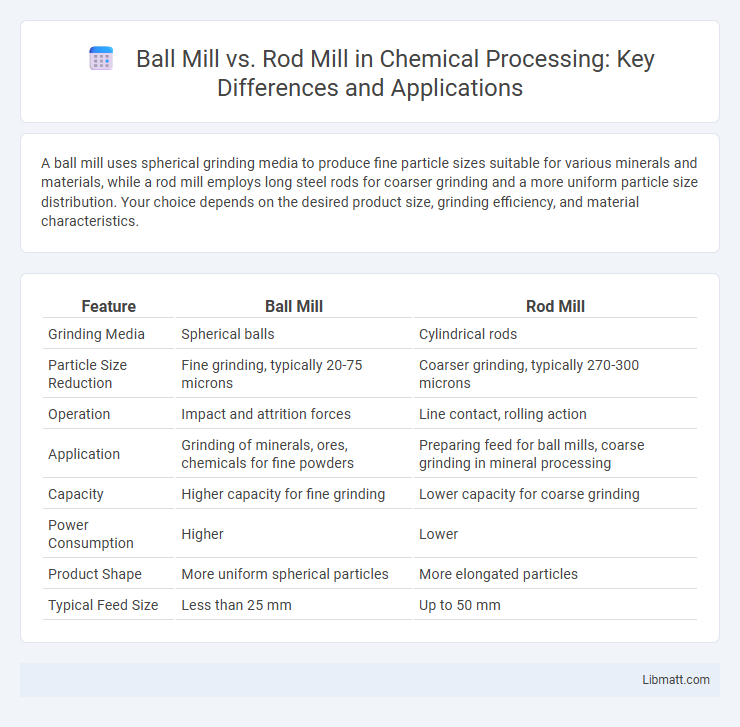

A ball mill uses spherical grinding media to produce fine particle sizes suitable for various minerals and materials, while a rod mill employs long steel rods for coarser grinding and a more uniform particle size distribution. Your choice depends on the desired product size, grinding efficiency, and material characteristics.

Table of Comparison

| Feature | Ball Mill | Rod Mill |

|---|---|---|

| Grinding Media | Spherical balls | Cylindrical rods |

| Particle Size Reduction | Fine grinding, typically 20-75 microns | Coarser grinding, typically 270-300 microns |

| Operation | Impact and attrition forces | Line contact, rolling action |

| Application | Grinding of minerals, ores, chemicals for fine powders | Preparing feed for ball mills, coarse grinding in mineral processing |

| Capacity | Higher capacity for fine grinding | Lower capacity for coarse grinding |

| Power Consumption | Higher | Lower |

| Product Shape | More uniform spherical particles | More elongated particles |

| Typical Feed Size | Less than 25 mm | Up to 50 mm |

Introduction to Ball Mills and Rod Mills

Ball mills and rod mills are essential grinding devices used in mineral processing to reduce ore particle size through impact and attrition. Ball mills use spherical grinding media for finer particle size reduction, while rod mills utilize long steel rods to achieve coarser grinding with a more uniform particle shape. Both mills operate in closed circuits with classifiers to optimize grinding efficiency and product size distribution.

Key Differences Between Ball Mills and Rod Mills

Ball mills use steel balls as the grinding medium, resulting in a finer and more uniform particle size suitable for grinding ores and minerals, while rod mills employ long steel rods that create a linear grinding action ideal for coarser materials. Ball mills typically operate with a higher speed, producing more impact force for efficient grinding, whereas rod mills run at lower speeds to minimize over-grinding and maintain particle shape. Understanding these key differences allows you to select the right mill type for optimizing your grinding process and maximizing throughput.

Working Principles of Ball Mills and Rod Mills

Ball mills operate using a rotating cylinder filled with steel or ceramic balls that crush material through impact and attrition, whereas rod mills use long steel rods that grind ore by tumbling within the mill, leveraging line contact instead of point contact. The grinding action in ball mills results in finer particles ideal for grinding minerals, while rod mills provide a coarser product suitable for grinding ores before further processing. Both mills rely on rotational motion to facilitate continuous tumbling and grinding, but the shape and size of the grinding media cause distinct differences in grinding efficiency and product size distribution.

Applications and Use Cases

Ball mills are ideal for fine grinding and are commonly used in mineral processing to produce fine particle sizes for ores such as gold, copper, and iron. Rod mills excel in grinding coarse materials into uniform size, making them suitable for preparing feed material for ball mills or grinding brittle materials like coal and limestone. Your choice between ball mill and rod mill depends on the feed size, desired product size, and specific industry application, such as cement production, mining, or chemical processing.

Grinding Media: Balls vs. Rods

Grinding media in ball mills consist of spherical balls that provide impact and attrition, making them ideal for finer grinding and producing uniform particle sizes. Rod mills use long steel rods which grind primarily through a rolling action, suitable for coarser grinding and reducing the risk of overgrinding your material. Choosing between balls and rods depends on your desired product size and grinding efficiency requirements.

Efficiency and Performance Comparison

Ball mills generally achieve higher grinding efficiency and finer particle size compared to rod mills due to their design, which promotes cascading and attrition actions. Rod mills excel in handling coarser feed materials and produce more uniform particle sizes, making them suitable for specific grinding applications where over-grinding must be minimized. Your choice between ball mill and rod mill should consider the desired product size and material characteristics to optimize performance and energy consumption.

Particle Size and Product Fineness

Ball mills produce finer particles compared to rod mills due to their smaller grinding media and higher impact forces, resulting in a more uniform particle size distribution. Rod mills generate coarser products with a more elongated particle shape, ideal for grinding ores before finer grinding in ball mills. Your choice depends on the desired product fineness and particle size, as ball mills excel in fine grinding while rod mills suit coarser grinding applications.

Operating Costs and Maintenance

Ball mills generally incur lower operating costs due to their energy efficiency and longer lifespan of grinding media compared to rod mills, which consume more power and require frequent rod replacements. Maintenance for ball mills is less intensive, involving periodic liner changes and bearing checks, whereas rod mills demand more frequent inspections and maintenance because of the elevated wear on rods and liners. Optimizing your choice between ball mill and rod mill based on these factors can significantly impact overall operational expenses and downtime.

Advantages and Disadvantages

Ball mills offer superior grinding efficiency and finer particle size production, making them ideal for processing hard, abrasive materials. Rod mills provide a more uniform particle size distribution and are better suited for grinding ores with a higher moisture content, but tend to have higher power consumption and lower grinding efficiency than ball mills. The choice between ball mill and rod mill depends on the specific material properties and desired product, with ball mills excelling in fine grinding and rod mills favored for coarser grinding tasks.

Choosing the Right Mill for Your Operation

Selecting the right mill for your operation depends on the material's hardness and particle size requirements, with ball mills suited for finer grinding of softer materials and rod mills preferred for coarser grinding of harder ores. You should evaluate throughput capacity and grinding efficiency, as ball mills offer higher capacity and better grinding efficiency, while rod mills provide more uniform particle size distribution. Understanding these differences ensures optimal productivity and energy consumption tailored to your specific milling needs.

ball mill vs rod mill Infographic

libmatt.com

libmatt.com