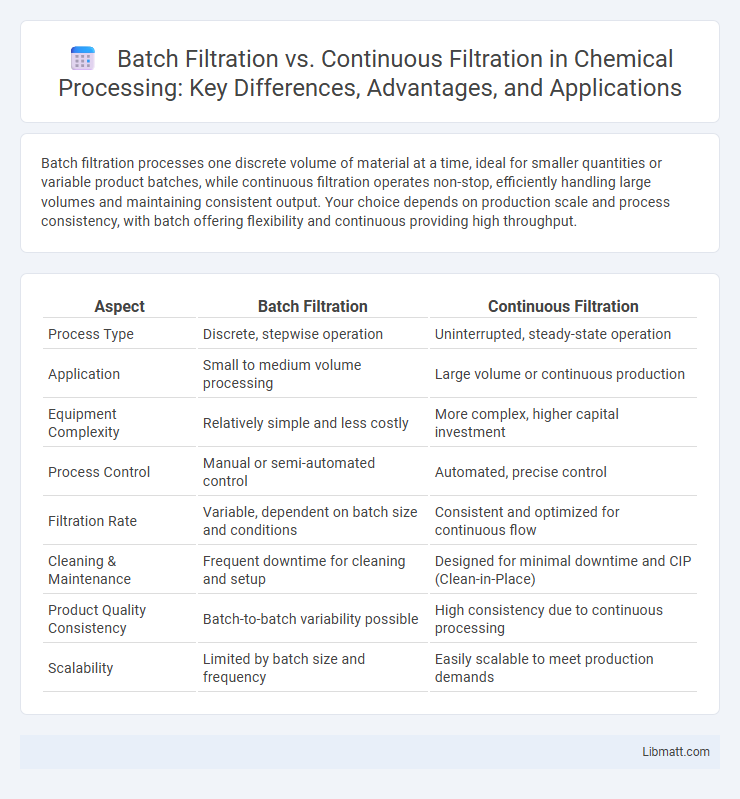

Batch filtration processes one discrete volume of material at a time, ideal for smaller quantities or variable product batches, while continuous filtration operates non-stop, efficiently handling large volumes and maintaining consistent output. Your choice depends on production scale and process consistency, with batch offering flexibility and continuous providing high throughput.

Table of Comparison

| Aspect | Batch Filtration | Continuous Filtration |

|---|---|---|

| Process Type | Discrete, stepwise operation | Uninterrupted, steady-state operation |

| Application | Small to medium volume processing | Large volume or continuous production |

| Equipment Complexity | Relatively simple and less costly | More complex, higher capital investment |

| Process Control | Manual or semi-automated control | Automated, precise control |

| Filtration Rate | Variable, dependent on batch size and conditions | Consistent and optimized for continuous flow |

| Cleaning & Maintenance | Frequent downtime for cleaning and setup | Designed for minimal downtime and CIP (Clean-in-Place) |

| Product Quality Consistency | Batch-to-batch variability possible | High consistency due to continuous processing |

| Scalability | Limited by batch size and frequency | Easily scalable to meet production demands |

Introduction to Filtration Processes

Filtration processes separate solids from liquids or gases using a porous medium, crucial in industries like pharmaceuticals, water treatment, and food production. Batch filtration involves processing a fixed volume of mixture per cycle, offering precise control and suitability for small-scale or variable production. Continuous filtration operates non-stop, ideal for large-scale operations demanding consistent output and efficiency in removing suspended particles.

Overview of Batch Filtration

Batch filtration involves processing a fixed volume of slurry or suspension in discrete cycles, allowing for precise control over separation parameters such as filtration time and cake thickness. This method is ideal for small to medium-scale operations where product consistency and flexibility in handling varying formulations are critical. Batch filtration systems typically utilize plate and frame filters, filter presses, or vacuum filter setups to achieve efficient solid-liquid separation.

Overview of Continuous Filtration

Continuous filtration is a process where slurry or suspension flows steadily through the filtration system, allowing for uninterrupted separation of solids from liquids. This method enhances efficiency by maintaining a constant operation, reducing downtime compared to batch filtration, which requires stops for loading and unloading. Your industrial processes benefit from higher throughput and consistent product quality with continuous filtration systems.

Key Differences Between Batch and Continuous Filtration

Batch filtration processes involve filtering fixed volumes of material in discrete steps, enabling precise control and customization for each batch, which suits small-scale or variable production. Continuous filtration operates non-stop, processing material streams consistently, enhancing efficiency and throughput for large-scale operations with steady input flow. Key differences include operational mode, scalability, process control, and suitability based on production volume and variability.

Advantages of Batch Filtration

Batch filtration offers precise control over filtration parameters, allowing operators to adjust conditions for different materials within each batch. It enhances product consistency and reduces cross-contamination risks by using isolated processing stages. This method is also cost-effective for small-scale productions, as it requires less initial investment in complex equipment compared to continuous filtration systems.

Advantages of Continuous Filtration

Continuous filtration offers increased efficiency by enabling nonstop processing, which reduces downtime and maximizes output in industrial applications. It provides consistent product quality by maintaining steady operating conditions and facilitates easier automation and scalability compared to batch filtration systems. The ability to handle large volumes and complex feed compositions makes continuous filtration ideal for pharmaceutical, food, and chemical production processes.

Common Applications of Batch Filtration

Batch filtration is widely used in pharmaceutical manufacturing for small to medium-scale production, allowing precise control over filtration parameters to ensure product purity. It is commonly employed in specialty chemical synthesis, where intermittent processing aligns with complex reaction cycles and quality control requirements. Food and beverage industries utilize batch filtration for juice clarification and wine filtration, benefiting from the flexibility to handle variable volumes and product variations.

Common Applications of Continuous Filtration

Continuous filtration is widely used in large-scale industrial processes such as wastewater treatment, chemical manufacturing, and food and beverage production where uninterrupted operation is crucial. Your facility benefits from enhanced efficiency and consistent product quality due to the steady removal of solids without process interruptions. This method is especially effective in applications requiring high throughput and minimal downtime, such as pharmaceutical production and mining slurry separation.

Factors Influencing Filtration Method Selection

Factors influencing filtration method selection include the volume of material, desired processing speed, and filtration efficiency. Batch filtration is ideal for smaller quantities or when precise control over each cycle is required, while continuous filtration suits large-scale operations needing consistent throughput. Your choice depends on operational scale, product sensitivity, and cost-effectiveness in achieving optimal separation.

Future Trends in Filtration Technologies

Emerging trends in filtration technologies emphasize increasing automation and integration of smart sensors for both batch and continuous filtration systems, enhancing precision and operational efficiency. Continuous filtration is gaining traction due to its ability to support large-scale, uninterrupted processing with improved energy efficiency and reduced downtime. Your choice between batch and continuous filtration will increasingly depend on the adoption of advanced materials and digital monitoring tools that optimize filtration performance and sustainability in evolving industrial applications.

batch filtration vs continuous filtration Infographic

libmatt.com

libmatt.com