Blown film extrusion produces tubular films with excellent strength and clarity, ideal for packaging and agricultural applications, while cast film extrusion creates flat films with uniform thickness and superior optical properties, commonly used in food packaging and lamination. Your choice depends on the desired film characteristics, processing speed, and end-use requirements.

Table of Comparison

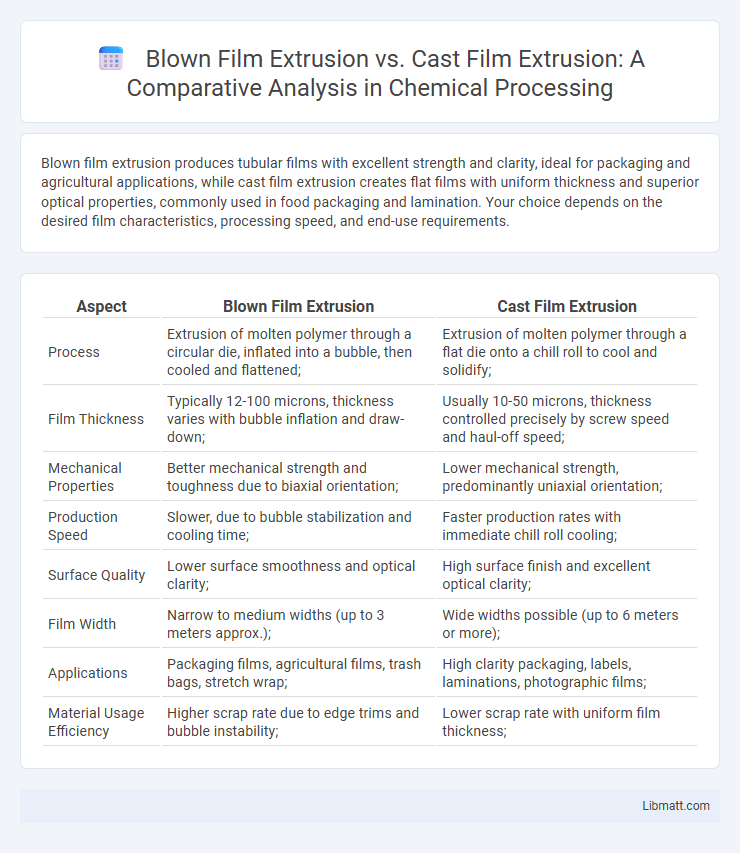

| Aspect | Blown Film Extrusion | Cast Film Extrusion |

|---|---|---|

| Process | Extrusion of molten polymer through a circular die, inflated into a bubble, then cooled and flattened; | Extrusion of molten polymer through a flat die onto a chill roll to cool and solidify; |

| Film Thickness | Typically 12-100 microns, thickness varies with bubble inflation and draw-down; | Usually 10-50 microns, thickness controlled precisely by screw speed and haul-off speed; |

| Mechanical Properties | Better mechanical strength and toughness due to biaxial orientation; | Lower mechanical strength, predominantly uniaxial orientation; |

| Production Speed | Slower, due to bubble stabilization and cooling time; | Faster production rates with immediate chill roll cooling; |

| Surface Quality | Lower surface smoothness and optical clarity; | High surface finish and excellent optical clarity; |

| Film Width | Narrow to medium widths (up to 3 meters approx.); | Wide widths possible (up to 6 meters or more); |

| Applications | Packaging films, agricultural films, trash bags, stretch wrap; | High clarity packaging, labels, laminations, photographic films; |

| Material Usage Efficiency | Higher scrap rate due to edge trims and bubble instability; | Lower scrap rate with uniform film thickness; |

Introduction to Film Extrusion Processes

Blown film extrusion and cast film extrusion are two primary plastic film manufacturing processes used in packaging, agriculture, and industrial applications. Blown film extrusion involves melting polymer and extruding it through a circular die to form a thin tube, which is expanded by air to create a bubble that is cooled and collapsed into film. Cast film extrusion drives molten polymer through a flat die, rapidly cooled on a chilled roller to produce smooth, uniform films with precise thickness control.

Overview of Blown Film Extrusion

Blown film extrusion involves melting polymer resins and forming a continuous tubular film by inflating the molten polymer through a circular die, creating a bubble that is cooled and collapsed into flat film. This process offers superior film uniformity, excellent mechanical properties, and enhanced clarity compared to cast film extrusion, making it ideal for applications like packaging, agricultural films, and shrink wraps. Key parameters influencing blown film quality include bubble stability, cooling rate, and frost line height, which directly impact film thickness, strength, and transparency.

Overview of Cast Film Extrusion

Cast film extrusion produces thin plastic films by melting polymer resin and extruding it through a flat die onto a chilled roller, resulting in smooth, high-quality films with excellent optical clarity and uniform thickness. This process is ideal for applications requiring precise gauge control, such as packaging, laminating, and printable substrates. Your choice of cast film extrusion ensures superior surface finish and faster cooling rates compared to blown film extrusion, enhancing product consistency and performance.

Key Differences Between Blown and Cast Film Extrusion

Blown film extrusion produces tubular films by inflating a molten polymer through a circular die, resulting in biaxial orientation and improved strength properties, whereas cast film extrusion involves extruding molten polymer onto a chilled roll, producing films with uniform thickness and excellent optical clarity due to uniaxial orientation. Blown films typically exhibit higher mechanical strength and better stretchability, making them ideal for packaging applications requiring durability, while cast films offer superior surface smoothness and dimensional stability, suited for printing and lamination. Processing speed varies as cast film extrusion operates at higher rates with easier tension control, whereas blown film extrusion demands precise air cooling and bubble stability, impacting production efficiency and film characteristics.

Material Compatibility and Selection

Blown film extrusion offers greater versatility in processing a wide range of thermoplastics such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), making it ideal for flexible packaging requiring high strength and clarity. Cast film extrusion excels with materials like low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), producing films with consistent thickness and superior surface finish suited for lamination and printing applications. Your choice between blown and cast film extrusion should consider specific material properties, processing temperatures, and end-use performance requirements to optimize film quality and functionality.

Processing Speeds and Efficiency Comparison

Blown film extrusion typically operates at slower processing speeds, ranging from 30 to 150 meters per minute, due to the cooling time required for the tubular film. Cast film extrusion, however, achieves higher efficiency with processing speeds of up to 300 meters per minute, benefiting from rapid cooling on chilled rollers. Your choice between these methods depends on balancing production volume needs with desired film properties and clarity.

Film Properties: Strength, Clarity, and Thickness

Blown film extrusion typically produces films with higher tensile strength and better puncture resistance due to the biaxial orientation achieved during the cooling and stretching process. Cast film extrusion offers superior clarity and a smoother surface finish since the film cools quickly on a chilled roller, resulting in less molecular orientation. Thickness control is more precise in cast film extrusion, allowing for uniform gauge and reduced variability compared to the more variable thickness typical in blown films.

Typical Applications for Blown vs. Cast Films

Blown film extrusion is typically used for packaging applications like plastic bags, agricultural films, and stretch wrap due to its excellent mechanical properties and versatility in film thickness. Cast film extrusion is preferred for high-clarity films used in food packaging, labels, and medical packaging where surface smoothness and optical properties are critical. Both processes serve diverse industries, but blown films are favored for durable, flexible solutions while cast films excel in applications requiring superior clarity and uniformity.

Cost Considerations and Operational Factors

Blown film extrusion typically incurs higher initial equipment costs and energy expenses due to its complex cooling systems and longer production times, while cast film extrusion offers lower operational costs with faster line speeds and simpler cooling methods. You should consider the balance between material usage efficiency in blown film, which can reduce waste, and the higher maintenance demands of its equipment compared to the low-maintenance, consistent output of cast film extrusion. Cost efficiency depends on your production scale and product specifications, with cast film often favored for high-volume, flat film applications and blown film suited for flexible packaging requiring greater film thickness uniformity.

Choosing the Right Film Extrusion Method

Choosing the right film extrusion method depends on your specific product requirements, including film thickness, clarity, and mechanical properties. Blown film extrusion offers superior tensile strength and stretchability, making it ideal for packaging films, while cast film extrusion provides better optical properties and uniform thickness suitable for high-quality printing applications. Understanding these differences helps optimize production efficiency and achieve the desired film performance for your business needs.

Blown film extrusion vs cast film extrusion Infographic

libmatt.com

libmatt.com