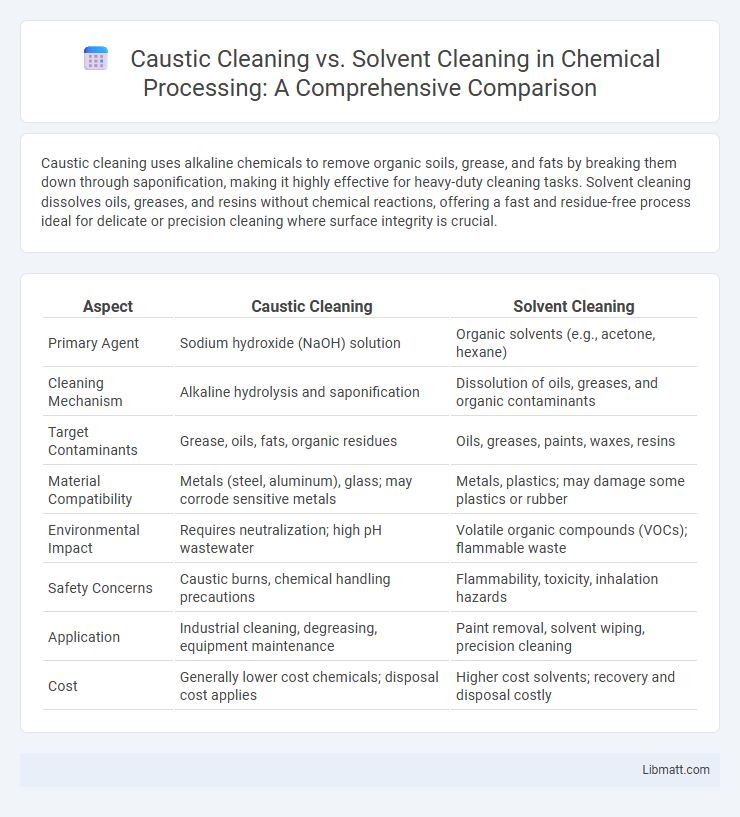

Caustic cleaning uses alkaline chemicals to remove organic soils, grease, and fats by breaking them down through saponification, making it highly effective for heavy-duty cleaning tasks. Solvent cleaning dissolves oils, greases, and resins without chemical reactions, offering a fast and residue-free process ideal for delicate or precision cleaning where surface integrity is crucial.

Table of Comparison

| Aspect | Caustic Cleaning | Solvent Cleaning |

|---|---|---|

| Primary Agent | Sodium hydroxide (NaOH) solution | Organic solvents (e.g., acetone, hexane) |

| Cleaning Mechanism | Alkaline hydrolysis and saponification | Dissolution of oils, greases, and organic contaminants |

| Target Contaminants | Grease, oils, fats, organic residues | Oils, greases, paints, waxes, resins |

| Material Compatibility | Metals (steel, aluminum), glass; may corrode sensitive metals | Metals, plastics; may damage some plastics or rubber |

| Environmental Impact | Requires neutralization; high pH wastewater | Volatile organic compounds (VOCs); flammable waste |

| Safety Concerns | Caustic burns, chemical handling precautions | Flammability, toxicity, inhalation hazards |

| Application | Industrial cleaning, degreasing, equipment maintenance | Paint removal, solvent wiping, precision cleaning |

| Cost | Generally lower cost chemicals; disposal cost applies | Higher cost solvents; recovery and disposal costly |

Introduction to Caustic and Solvent Cleaning

Caustic cleaning involves the use of alkaline solutions, typically sodium hydroxide, to effectively remove organic soils such as fats, oils, and greases by saponification and emulsification. Solvent cleaning utilizes organic solvents like hydrocarbons or chlorinated compounds to dissolve and lift away non-polar contaminants such as oils, greases, and adhesives without water. Both methods are widely employed in industrial cleaning processes, with caustic cleaning favored for heavy-duty degreasing and solvent cleaning preferred for precision parts and residue-free finishes.

Definitions: What is Caustic Cleaning?

Caustic cleaning involves using alkaline solutions, typically containing sodium hydroxide or potassium hydroxide, to remove organic soils such as fats, oils, and greases from surfaces. This chemical process saponifies fatty acids, breaking down complex organic matter into water-soluble compounds for easier rinsing. Caustic cleaning is widely applied in industries like food processing, metal fabrication, and petrochemical maintenance due to its effectiveness in heavy-duty degreasing.

What is Solvent Cleaning?

Solvent cleaning uses chemical solvents to dissolve and remove grease, oils, and contaminants from surfaces, making it ideal for precision cleaning in industries like electronics and automotive. This method is effective for breaking down organic residues that water-based caustic cleaners may not eliminate. Your choice between caustic and solvent cleaning depends on the material compatibility and the nature of the contaminants involved.

Key Differences Between Caustic and Solvent Cleaning

Caustic cleaning uses alkaline solutions, primarily sodium hydroxide, to remove organic soils like fats, oils, and greases by chemically breaking them down, making it highly effective for heavy-duty degreasing. Solvent cleaning employs organic solvents such as hydrocarbons or chlorinated solvents to dissolve oils, waxes, and other hydrophobic contaminants through physical solubilization without chemical reaction. Key differences include caustic cleaning's reliance on chemical saponification and higher water compatibility versus solvent cleaning's ability to target non-polar substances and lower environmental impact when using modern, less toxic solvents.

Applications: When to Use Caustic or Solvent Cleaning

Caustic cleaning excels in industrial applications involving heavy grease, oils, and organic residues commonly found in food processing, metalworking, and automotive industries due to its strong alkaline properties. Solvent cleaning is preferred for removing non-polar contaminants like oils, waxes, and adhesives from electronics, precision instruments, and delicate surfaces where minimal residue and rapid evaporation are critical. Selecting between caustic and solvent cleaning depends largely on the type of contaminant, material compatibility, and environmental or safety considerations in the specific application.

Effectiveness on Different Contaminants

Caustic cleaning excels at removing organic contaminants such as oils, greases, and proteins due to its alkaline nature that breaks down these substances effectively. Solvent cleaning is more effective for dissolving non-polar contaminants like hydrocarbons, paints, and adhesives because solvents can dissolve these materials at a molecular level. The choice between caustic and solvent cleaning depends on the specific type of contaminant, with caustic cleaning preferred for polar, organic residues and solvent cleaning for non-polar, hydrophobic substances.

Safety Considerations and Environmental Impact

Caustic cleaning involves strong alkaline solutions that require careful handling due to their corrosive nature, posing risks such as chemical burns and inhalation hazards, while solvent cleaning often uses volatile organic compounds (VOCs) that are flammable and toxic, demanding strict ventilation and protective equipment. Environmentally, caustic cleaners can generate hazardous alkaline waste that must be neutralized before disposal to prevent water pollution, whereas solvents contribute to air pollution through VOC emissions and may persist in the environment, leading to long-term ecological damage. Choosing between caustic and solvent cleaning methods requires evaluating both worker safety protocols and compliance with environmental regulations focused on hazardous waste management and emission controls.

Cost Comparison: Caustic vs Solvent Cleaning

Caustic cleaning typically offers lower upfront costs compared to solvent cleaning due to the affordability of caustic chemicals and simpler handling requirements. However, solvent cleaning may incur higher expenses related to solvent recovery, disposal, and stricter environmental regulations. Your choice should factor in total lifecycle costs, including maintenance, waste treatment, and regulatory compliance for accurate cost comparison.

Equipment and Process Requirements

Caustic cleaning requires specialized equipment resistant to high pH levels, such as stainless steel tanks and heating elements for maintaining elevated temperatures, while solvent cleaning typically uses closed-loop systems designed to safely handle flammable liquids and vapors. The caustic process involves alkaline chemical baths and rinsing steps to remove organic and inorganic soils, demanding corrosion-resistant materials and precise temperature control, whereas solvent cleaning employs organic compounds to dissolve oils and greases, necessitating vapor recovery units and explosion-proof ventilation systems. Understanding these equipment and process requirements helps you select the most effective cleaning method tailored to your operational safety and environmental regulations.

Choosing the Right Cleaning Method for Your Needs

Caustic cleaning uses alkaline solutions to effectively remove organic soils like grease and oils, making it ideal for heavy-duty industrial applications. Solvent cleaning dissolves non-polar contaminants such as hydrocarbons, offering fast evaporation and minimal residue for precision equipment. Selecting the appropriate method depends on surface material, type of contaminants, environmental impact, and regulatory compliance.

Caustic cleaning vs solvent cleaning Infographic

libmatt.com

libmatt.com