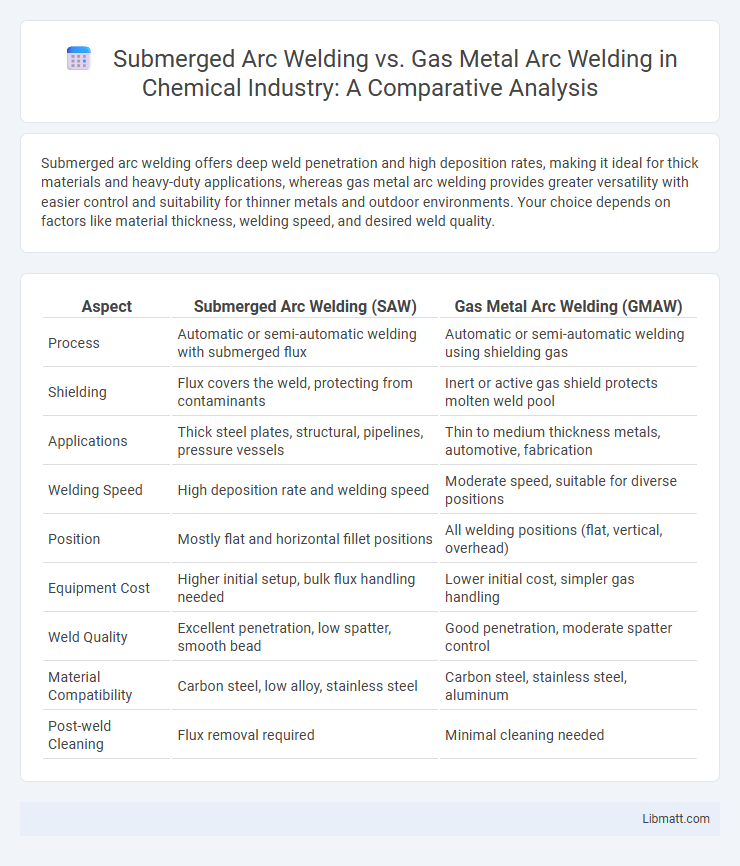

Submerged arc welding offers deep weld penetration and high deposition rates, making it ideal for thick materials and heavy-duty applications, whereas gas metal arc welding provides greater versatility with easier control and suitability for thinner metals and outdoor environments. Your choice depends on factors like material thickness, welding speed, and desired weld quality.

Table of Comparison

| Aspect | Submerged Arc Welding (SAW) | Gas Metal Arc Welding (GMAW) |

|---|---|---|

| Process | Automatic or semi-automatic welding with submerged flux | Automatic or semi-automatic welding using shielding gas |

| Shielding | Flux covers the weld, protecting from contaminants | Inert or active gas shield protects molten weld pool |

| Applications | Thick steel plates, structural, pipelines, pressure vessels | Thin to medium thickness metals, automotive, fabrication |

| Welding Speed | High deposition rate and welding speed | Moderate speed, suitable for diverse positions |

| Position | Mostly flat and horizontal fillet positions | All welding positions (flat, vertical, overhead) |

| Equipment Cost | Higher initial setup, bulk flux handling needed | Lower initial cost, simpler gas handling |

| Weld Quality | Excellent penetration, low spatter, smooth bead | Good penetration, moderate spatter control |

| Material Compatibility | Carbon steel, low alloy, stainless steel | Carbon steel, stainless steel, aluminum |

| Post-weld Cleaning | Flux removal required | Minimal cleaning needed |

Introduction to Submerged Arc Welding (SAW) and Gas Metal Arc Welding (GMAW)

Submerged Arc Welding (SAW) utilizes a granular flux to shield the weld zone, enabling deep weld penetration and high deposition rates ideal for thick materials. Gas Metal Arc Welding (GMAW), also known as MIG welding, employs a continuous wire electrode and shielding gas to produce clean, versatile welds suitable for thinner metals and varied positions. Your choice between SAW and GMAW depends on factors like material thickness, welding speed, and desired weld quality.

Fundamental Principles of SAW and GMAW

Submerged arc welding (SAW) operates by creating an arc between a continuously fed electrode and the workpiece, with the arc submerged under a blanket of granular flux, which protects the weld pool from atmospheric contamination and stabilizes the arc. Gas metal arc welding (GMAW), also known as MIG welding, uses a continuous solid wire electrode and an externally supplied shielding gas to protect the weld pool from oxidation and contamination. SAW is primarily used for thick materials due to its deep weld penetration and high deposition rates, while GMAW offers versatility with faster welding speeds and suitability for thinner materials.

Equipment and Setup Comparison

Submerged arc welding (SAW) equipment involves a heavy-duty power source, a continuously fed consumable electrode, and a granular flux delivery system, requiring a large setup often used for thick materials and high deposition rates. Gas metal arc welding (GMAW) uses a more compact welding gun with a shielding gas supply, a wire feeder, and a power source suitable for thinner materials and more versatile applications. Your choice between these methods depends on the specific equipment size, complexity, and the precision needed for the welding task.

Process Mechanism: SAW vs GMAW

Submerged Arc Welding (SAW) uses a continuously fed consumable electrode and a blanket of granular flux to create a molten weld pool, protecting the weld from atmospheric contamination and allowing deep weld penetration. Gas Metal Arc Welding (GMAW) employs a wire electrode and an external shielding gas to protect the weld pool, offering greater versatility and ease of automation in various positions. Your choice depends on factors like material thickness, welding speed, and required weld quality, as SAW excels in heavy-duty applications while GMAW is more adaptable for thin materials and complex geometries.

Material Compatibility and Applications

Submerged arc welding (SAW) is highly compatible with thick, heavy steel materials, making it ideal for large-scale structural components, pressure vessels, and shipbuilding, while gas metal arc welding (GMAW) suits a wider range of metals, including carbon steel, stainless steel, and aluminum, especially in automotive and fabrication industries. SAW excels in high-deposition rate welding for long, straight welds on heavy plates, whereas GMAW offers versatility and precision for thinner materials and complex geometries. Your choice between SAW and GMAW depends on the specific material thickness and application requirements to ensure optimal weld quality and efficiency.

Welding Speed and Productivity

Submerged arc welding (SAW) offers significantly higher welding speeds, often reaching up to 12 meters per minute, which enhances overall productivity in heavy industrial applications. Gas metal arc welding (GMAW) typically achieves welding speeds around 3 to 5 meters per minute, making it suitable for thinner materials and more precise applications. The continuous flux coverage in SAW reduces spatter and allows uninterrupted operation, boosting efficiency compared to the more operator-dependent GMAW process.

Quality and Weld Appearance

Submerged arc welding (SAW) delivers superior weld quality with deeper penetration and minimal spatter, resulting in clean, smooth weld beads ideal for thick materials and automated processes. Gas metal arc welding (GMAW) offers versatile weld appearance suitable for thinner metals and complex joints but may produce more surface irregularities and require post-weld cleaning. Your choice depends on the need for superior structural integrity with SAW or the flexibility and aesthetic control of GMAW welds.

Cost and Efficiency Analysis

Submerged arc welding (SAW) generally offers higher deposition rates and deeper weld penetration, resulting in superior efficiency for thick materials compared to gas metal arc welding (GMAW). While SAW equipment and setup costs can be higher initially, its lower labor and filler material consumption often lead to reduced overall operational expenses. Your choice depends on balancing the upfront investment against long-term productivity and cost savings for specific welding applications.

Safety Considerations and Environmental Impact

Submerged arc welding (SAW) offers enhanced safety by minimizing arc exposure and reducing harmful UV radiation compared to gas metal arc welding (GMAW), which requires more protective measures due to visible sparks and fumes. SAW produces less smoke and fewer airborne contaminants, leading to a cleaner work environment and lower health risks for operators. Your choice between SAW and GMAW should consider these safety factors alongside environmental regulations and workplace ventilation capabilities.

Choosing the Right Welding Process: SAW vs GMAW

Submerged Arc Welding (SAW) offers deeper penetration and higher deposition rates, making it ideal for thick materials and heavy industrial applications, while Gas Metal Arc Welding (GMAW) provides greater versatility and ease of use for thinner metals and more precise welds. Your choice between SAW and GMAW should depend on factors such as material thickness, desired weld quality, production speed, and cost-efficiency. For large-scale structural projects requiring consistent, high-quality welds, SAW typically delivers superior productivity, whereas GMAW excels in applications requiring flexibility and welding in various positions.

Submerged arc welding vs gas metal arc welding Infographic

libmatt.com

libmatt.com