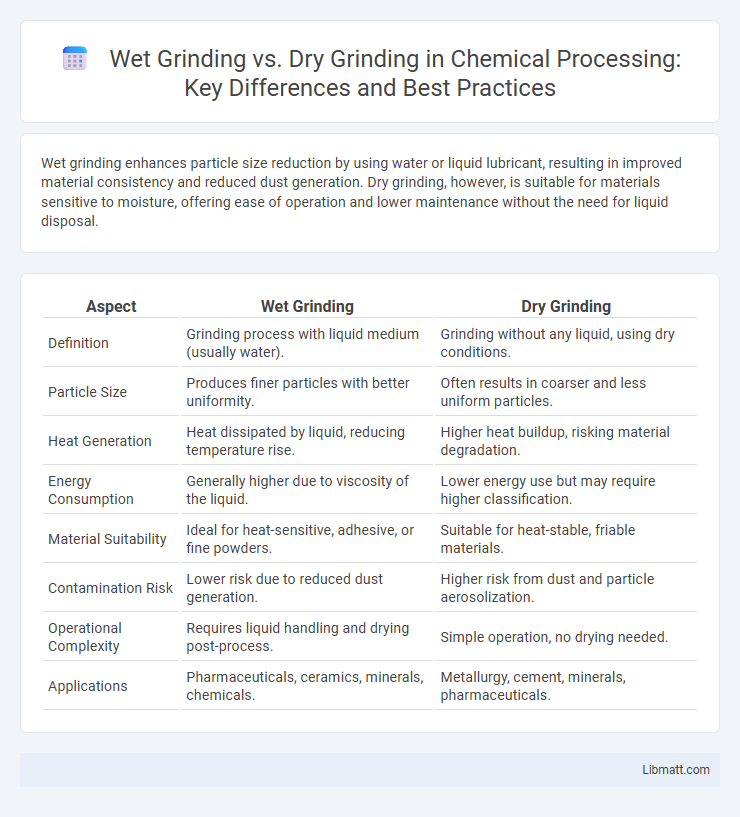

Wet grinding enhances particle size reduction by using water or liquid lubricant, resulting in improved material consistency and reduced dust generation. Dry grinding, however, is suitable for materials sensitive to moisture, offering ease of operation and lower maintenance without the need for liquid disposal.

Table of Comparison

| Aspect | Wet Grinding | Dry Grinding |

|---|---|---|

| Definition | Grinding process with liquid medium (usually water). | Grinding without any liquid, using dry conditions. |

| Particle Size | Produces finer particles with better uniformity. | Often results in coarser and less uniform particles. |

| Heat Generation | Heat dissipated by liquid, reducing temperature rise. | Higher heat buildup, risking material degradation. |

| Energy Consumption | Generally higher due to viscosity of the liquid. | Lower energy use but may require higher classification. |

| Material Suitability | Ideal for heat-sensitive, adhesive, or fine powders. | Suitable for heat-stable, friable materials. |

| Contamination Risk | Lower risk due to reduced dust generation. | Higher risk from dust and particle aerosolization. |

| Operational Complexity | Requires liquid handling and drying post-process. | Simple operation, no drying needed. |

| Applications | Pharmaceuticals, ceramics, minerals, chemicals. | Metallurgy, cement, minerals, pharmaceuticals. |

Introduction to Wet and Dry Grinding

Wet grinding involves the use of liquid, typically water, to reduce particle size and improve material handling, resulting in finer and more uniform textures in processes like minerals and food production. Dry grinding eliminates the need for liquids, making it suitable for materials sensitive to moisture or applications requiring dry powders, such as cement or certain chemicals. Your choice between wet and dry grinding depends on factors like moisture sensitivity, desired final particle size, and process efficiency.

Key Differences Between Wet and Dry Grinding

Wet grinding uses liquid, typically water, to reduce particle size, which helps in controlling dust and improving material flow, whereas dry grinding processes materials without any moisture, often resulting in higher heat generation. Wet grinding is preferred for fine or slurry products, enhancing separation efficiency, while dry grinding is faster and more energy-efficient for coarse materials. Understanding these key differences can help you select the optimal grinding method based on your material characteristics and processing goals.

Material Suitability for Wet and Dry Grinding

Wet grinding is suitable for materials that are heat-sensitive or prone to dust generation, such as minerals, pigments, and certain chemicals, as the liquid medium helps dissipate heat and suppress dust. Dry grinding works well with hard, brittle materials like ores and cement clinker that do not react adversely to heat or moisture and require easier handling and storage. Your choice depends on the material's moisture tolerance, heat sensitivity, and the desired particle size distribution.

Equipment Used in Wet and Dry Grinding Processes

Wet grinding equipment typically includes ball mills, stirrers, and attritors designed with features to handle slurries, enabling effective particle size reduction and improved suspension of materials. Dry grinding commonly utilizes ball mills, hammer mills, jet mills, and roller mills equipped with air classifiers and dust collection systems to manage fine powders and minimize dust emissions. Selection of equipment depends on material characteristics, desired particle size, and post-processing requirements in industries such as mineral processing, pharmaceuticals, and ceramics.

Energy Consumption: Wet vs Dry Grinding

Wet grinding consumes less energy compared to dry grinding due to the presence of water, which reduces friction and improves grinding efficiency. The lubrication effect in wet grinding lowers the power requirement, leading to energy savings of up to 30% in various industrial applications. Conversely, dry grinding requires higher energy input to overcome particle friction and heat generation, resulting in increased operational costs.

Impact on Product Quality and Particle Size

Wet grinding enhances product quality by producing finer and more uniform particle sizes due to the suspension of materials in liquid, reducing heat generation and minimizing particle agglomeration. Dry grinding may cause higher temperatures leading to particle size variation and potential degradation of heat-sensitive materials. Your choice between wet and dry grinding directly influences particle size distribution and the consistency of the final product quality.

Environmental Considerations

Wet grinding significantly reduces dust emissions and airborne particles, minimizing respiratory hazards and environmental pollution compared to dry grinding. The process consumes water, which requires proper management and recycling to prevent wastewater contamination and conserve resources. Dry grinding consumes less water but generates higher dust levels, necessitating efficient dust control systems to mitigate environmental impact.

Cost Comparison: Wet vs Dry Grinding

Wet grinding typically incurs higher operational costs due to water usage, waste treatment, and energy consumption for slurry pumping, whereas dry grinding reduces water-related expenses but may require more maintenance to manage dust and equipment wear. Equipment costs for wet grinding can be higher because of corrosion-resistant materials and additional sealing, while dry grinding machinery tends to have lower upfront costs but increased dust control investments. Your choice between wet and dry grinding should consider these cost factors alongside material characteristics and environmental regulations.

Common Applications of Wet and Dry Grinding

Wet grinding is commonly applied in mineral processing, paint manufacturing, and pharmaceuticals where fine particle size and dispersion are crucial, using liquids like water to enhance grinding efficiency and reduce heat. Dry grinding is preferred in cement production, mining, and food milling for materials sensitive to moisture, allowing easier handling of powders without the need for drying processes. Selecting between wet and dry grinding depends on the material's moisture sensitivity, desired particle size distribution, and subsequent processing requirements.

Choosing the Right Grinding Method for Your Needs

Selecting between wet grinding and dry grinding depends on your material type and desired final product quality. Wet grinding is ideal for abrasive or heat-sensitive materials, offering better particle size control and reduced dust, while dry grinding suits materials that need to remain free from moisture and can tolerate higher temperatures. Your choice should consider processing efficiency, product specifications, and downstream handling requirements.

Wet grinding vs dry grinding Infographic

libmatt.com

libmatt.com