Chlorinated polyethylene offers excellent weather resistance, flexibility, and chemical stability, making it ideal for flexible hoses and roofing membranes, while polychloroprene (neoprene) provides superior abrasion resistance, good elasticity, and resistance to oils and solvents, commonly used in wetsuits and industrial gaskets. Your choice depends on the specific environmental exposure and mechanical requirements of the application.

Table of Comparison

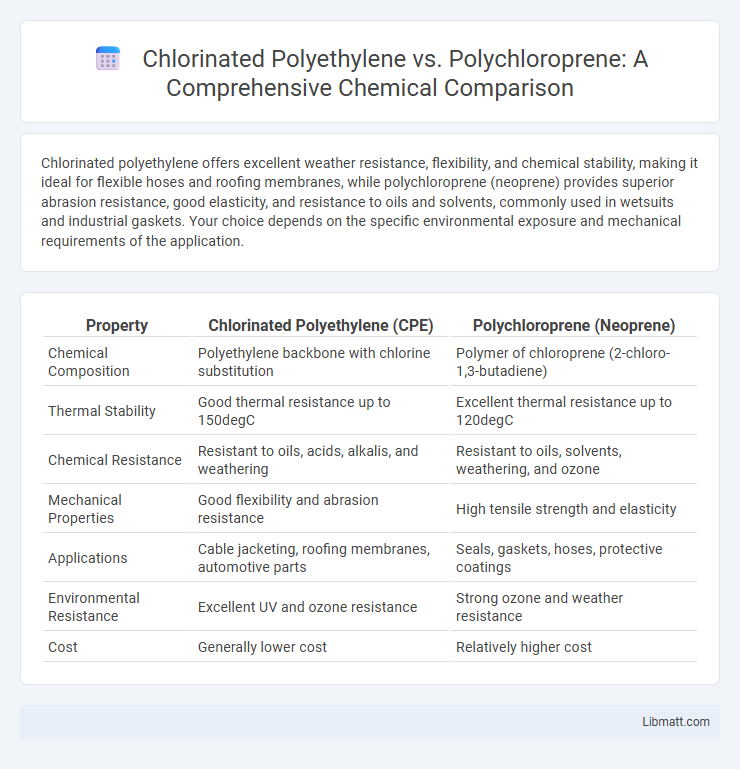

| Property | Chlorinated Polyethylene (CPE) | Polychloroprene (Neoprene) |

|---|---|---|

| Chemical Composition | Polyethylene backbone with chlorine substitution | Polymer of chloroprene (2-chloro-1,3-butadiene) |

| Thermal Stability | Good thermal resistance up to 150degC | Excellent thermal resistance up to 120degC |

| Chemical Resistance | Resistant to oils, acids, alkalis, and weathering | Resistant to oils, solvents, weathering, and ozone |

| Mechanical Properties | Good flexibility and abrasion resistance | High tensile strength and elasticity |

| Applications | Cable jacketing, roofing membranes, automotive parts | Seals, gaskets, hoses, protective coatings |

| Environmental Resistance | Excellent UV and ozone resistance | Strong ozone and weather resistance |

| Cost | Generally lower cost | Relatively higher cost |

Introduction to Chlorinated Polyethylene and Polychloroprene

Chlorinated polyethylene (CPE) is a synthetic polymer known for its excellent weather resistance, chemical stability, and flexibility, often used in wire insulation, roofing membranes, and automotive parts. Polychloroprene, commonly known as neoprene, offers superior elasticity, chemical resistance, and durability, making it ideal for wetsuits, gaskets, and adhesives. Your choice between CPE and polychloroprene depends on the specific performance requirements, such as resistance to oils, heat, or environmental conditions.

Chemical Structure Comparison

Chlorinated polyethylene (CPE) features a polyethylene backbone with chlorine atoms randomly substituted, enhancing its chemical resistance and flexibility. Polychloroprene (neoprene) consists of a polydiene chain with chlorine atoms attached to its double bonds, providing higher elasticity and weather resistance. Understanding these chemical structure differences can help you select the right material for applications requiring specific mechanical and chemical properties.

Key Physical and Mechanical Properties

Chlorinated polyethylene (CPE) exhibits excellent chemical resistance, flexibility, and impact strength, making it suitable for applications requiring durability in harsh conditions. Polychloroprene (CR), also known as neoprene, offers superior tensile strength, abrasion resistance, and compression set stability, ideal for seals and gaskets. Both materials have good weather resistance, but polychloroprene outperforms in maintaining mechanical integrity under prolonged exposure to heat and ozone.

Heat and Weather Resistance

Chlorinated polyethylene (CPE) demonstrates excellent heat resistance, maintaining stability in temperatures up to 130degC and offering superior weather resistance due to its strong resistance to UV radiation, ozone, and chemicals. Polychloroprene (neoprene) withstands moderate heat, typically up to 120degC, while providing robust resistance to ozone, weathering, and flame exposure, making it ideal for outdoor applications. Your choice between CPE and polychloroprene should consider the specific environmental conditions and thermal demands of your project for optimal durability.

Chemical and Oil Resistance

Chlorinated polyethylene (CPE) exhibits excellent chemical resistance and superior oil resistance, making it ideal for applications exposed to harsh chemicals and petroleum products. Polychloroprene (neoprene) also provides good resistance to oils and chemicals but generally performs better in moderate chemical environments with higher resistance to weathering and ozone. When selecting between CPE and polychloroprene, consider your specific exposure to aggressive oils or chemical agents to ensure optimal material performance.

Applications in Industry

Chlorinated polyethylene (CPE) is extensively used in the automotive industry for wire and cable insulation, roofing membranes, and flexible hoses due to its excellent weather, chemical, and ozone resistance. Polychloroprene (neoprene) finds broad applications in industrial gloves, wetsuits, adhesives, and gasketing materials thanks to its superior elasticity, oil resistance, and thermal stability. Both polymers serve critical roles in manufacturing durable products exposed to harsh environmental and mechanical conditions.

Processing and Manufacturing Differences

Chlorinated polyethylene (CPE) is processed through standard thermoplastic techniques like extrusion and molding, allowing for easy shaping and recycling due to its thermoplastic nature. Polychloroprene (CR), in contrast, is typically vulcanized during manufacturing, requiring heat and curing agents, resulting in a thermoset rubber with superior elasticity and chemical resistance. Your choice between CPE and CR should account for these processing differences, as CPE offers easier fabrication while CR provides enhanced performance in demanding applications.

Cost and Availability

Chlorinated polyethylene (CPE) generally offers a lower cost compared to polychloroprene (neoprene), making it a more budget-friendly option for large-scale industrial applications. CPE is widely available and produced in large quantities, ensuring steady supply for manufacturing purposes. Polychloroprene, although more expensive, provides superior performance in harsh environments but can be less readily accessible due to its specialized production requirements.

Environmental Impact and Safety

Chlorinated polyethylene (CPE) offers improved chemical resistance and UV stability with relatively low environmental toxicity but poses challenges in recycling due to chlorine content. Polychloroprene (CR), commonly known as neoprene, demonstrates higher durability and flame resistance but can release harmful chlorinated compounds during production and combustion, impacting environmental safety. You should consider that CPE generally has a lower environmental impact in disposal, whereas CR's manufacturing process requires stringent safety controls to minimize harmful emissions.

Choosing Between Chlorinated Polyethylene and Polychloroprene

Chlorinated polyethylene (CPE) offers superior chemical resistance and flexibility, making it ideal for applications involving harsh environments and exposure to oils or fuels. Polychloroprene (Neoprene) excels in durability, weather resistance, and mechanical strength, suitable for automotive and industrial seals or gaskets. The choice between CPE and polychloroprene depends on specific requirements such as chemical exposure, temperature tolerance, and mechanical stress in the intended application.

Chlorinated polyethylene vs polychloroprene Infographic

libmatt.com

libmatt.com