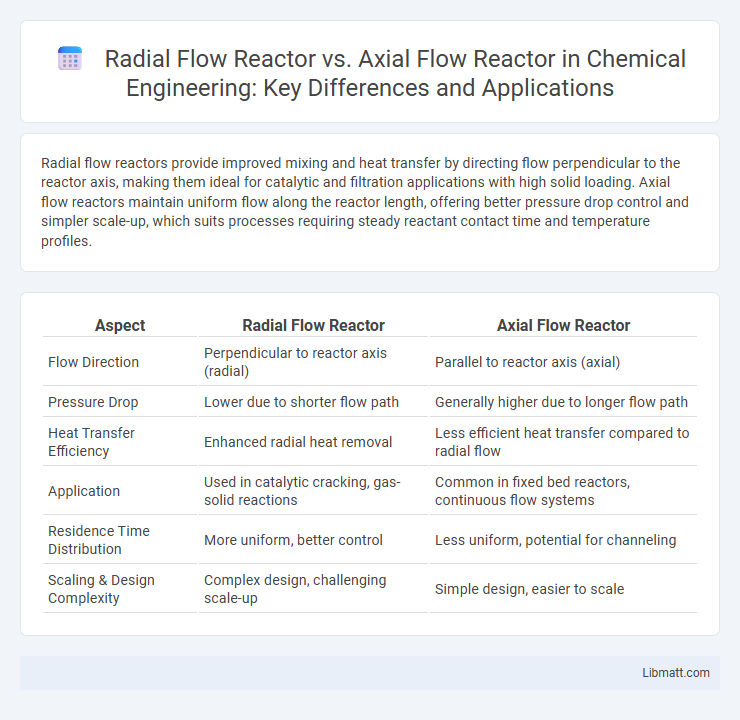

Radial flow reactors provide improved mixing and heat transfer by directing flow perpendicular to the reactor axis, making them ideal for catalytic and filtration applications with high solid loading. Axial flow reactors maintain uniform flow along the reactor length, offering better pressure drop control and simpler scale-up, which suits processes requiring steady reactant contact time and temperature profiles.

Table of Comparison

| Aspect | Radial Flow Reactor | Axial Flow Reactor |

|---|---|---|

| Flow Direction | Perpendicular to reactor axis (radial) | Parallel to reactor axis (axial) |

| Pressure Drop | Lower due to shorter flow path | Generally higher due to longer flow path |

| Heat Transfer Efficiency | Enhanced radial heat removal | Less efficient heat transfer compared to radial flow |

| Application | Used in catalytic cracking, gas-solid reactions | Common in fixed bed reactors, continuous flow systems |

| Residence Time Distribution | More uniform, better control | Less uniform, potential for channeling |

| Scaling & Design Complexity | Complex design, challenging scale-up | Simple design, easier to scale |

Introduction to Flow Reactors

Radial flow reactors feature gas or fluid flow moving perpendicularly from the reactor center toward its outer edge, optimizing catalyst surface utilization and reducing pressure drop. Axial flow reactors allow fluid to move parallel to the reactor's axis, providing uniform velocity and temperature profiles ideal for large-scale production. Understanding these flow patterns helps you select the appropriate reactor design for efficiency, scalability, and specific reaction dynamics.

Overview of Radial Flow Reactors

Radial flow reactors feature fluid movement perpendicular to the reactor axis, allowing enhanced mass transfer and better temperature control compared to axial flow reactors. These reactors are commonly used in catalytic processes, such as catalytic cracking, due to their ability to handle high-solid loads and minimize pressure drop. Your choice of a radial flow reactor can improve conversion efficiency and catalyst life in applications requiring uniform flow distribution and effective heat management.

Overview of Axial Flow Reactors

Axial flow reactors feature reactants flowing parallel to the reactor axis, promoting uniform temperature distribution and improved catalyst utilization. These reactors are commonly used in processes requiring precise residence time control, such as catalytic cracking and steam reforming. Their design enhances heat transfer efficiency and simplifies scale-up compared to radial flow reactors.

Design Principles: Radial vs Axial Flow

Radial flow reactors utilize a design where fluid moves perpendicular to the reactor axis, enabling uniform distribution and efficient heat transfer, making them ideal for catalytic cracking and filtration processes. Axial flow reactors feature fluid flow parallel to the reactor axis, which supports higher throughput and straightforward scaling in applications such as chemical synthesis and polymerization. Your selection between radial and axial flow designs should consider factors like pressure drop, residence time, and reaction uniformity to optimize reactor performance.

Flow Patterns and Mixing Characteristics

Radial flow reactors feature flow moving perpendicular to the reactor axis, promoting uniform velocity distribution and enhanced radial mixing that improves mass and heat transfer rates. Axial flow reactors exhibit flow along the reactor length, providing plug flow patterns with limited radial mixing, which is suitable for processes requiring controlled residence time and minimal back-mixing. Your choice between these reactors depends on the desired balance of mixing intensity and flow uniformity for optimal reaction performance.

Mass and Heat Transfer Efficiency

Radial flow reactors exhibit superior mass and heat transfer efficiency due to their perpendicular flow pattern, which enhances uniform distribution and reduces channeling compared to axial flow reactors. Axial flow reactors face limitations in heat dissipation and concentration gradients along the flow direction, potentially resulting in hotspots and reduced reaction rates. Selecting a radial flow reactor can optimize Your process by improving thermal management and promoting better reactant contact.

Industrial Applications and Use Cases

Radial flow reactors are widely used in catalytic cracking and gasification processes due to their superior mixing and heat transfer capabilities, making them ideal for handling solid catalysts and multiphase reactions. Axial flow reactors dominate in applications such as hydrogenation and polymerization where uniform flow and precise temperature control are critical for product consistency and reaction efficiency. Your choice between these reactors should depend on the specific industrial process requirements, such as catalyst type, reaction kinetics, and desired throughput.

Advantages of Radial Flow Reactors

Radial flow reactors offer improved mass transfer and uniform flow distribution due to their perpendicular flow orientation, enhancing reaction efficiency and catalyst utilization. They typically exhibit lower pressure drop compared to axial flow reactors, reducing energy consumption and operational costs. Your chemical processes benefit from increased scalability and easier maintenance with radial flow designs, making them ideal for large-scale industrial applications.

Advantages of Axial Flow Reactors

Axial flow reactors offer superior plug flow behavior, resulting in uniform reactant distribution and enhanced conversion efficiency, especially for catalytic processes. These reactors facilitate better temperature control along the reactor length, reducing hotspots and improving catalyst lifespan. Their design allows for scalability and easier modeling, making them ideal for continuous industrial applications requiring precise reaction control.

Selection Criteria: Choosing the Right Reactor

Selecting between radial flow reactors and axial flow reactors depends on factors such as pressure drop, residence time distribution, and catalyst utilization. Radial flow reactors are preferred for high flow rates and large catalyst volumes due to efficient flow distribution and low pressure drop, whereas axial flow reactors offer simpler design and better control in low-flow or low-pressure applications. Key considerations include reaction kinetics, reactor scale, and thermal management requirements to optimize performance and operational efficiency.

Radial flow reactor vs axial flow reactor Infographic

libmatt.com

libmatt.com