Dry process involves roasting coffee beans using hot air, resulting in a fruitier and heavier-bodied coffee, while the wet process uses water to remove the outer fruit layer, producing a cleaner and brighter cup. Your choice between dry and wet processes impacts the flavor profile and acidity of the coffee significantly.

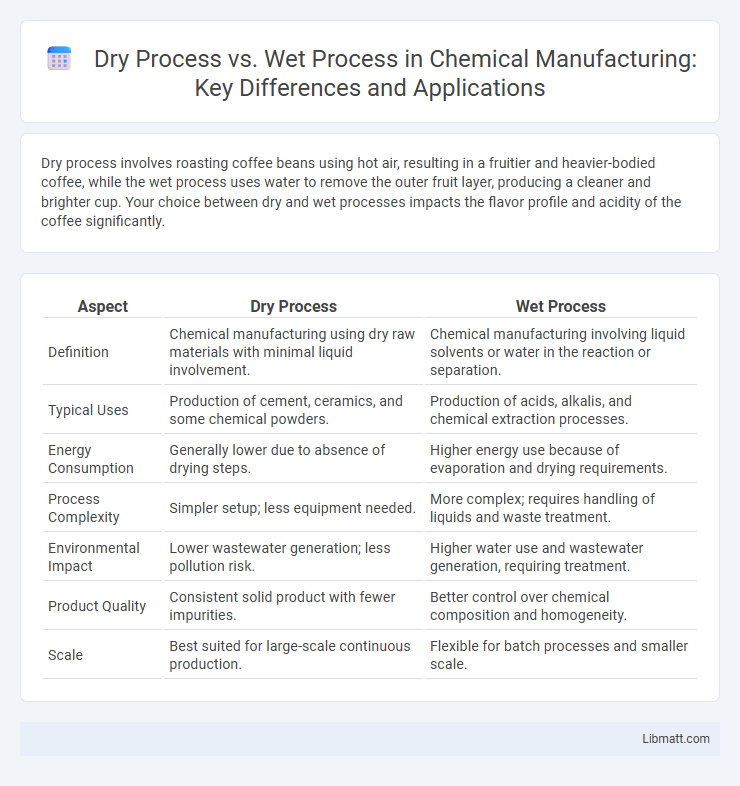

Table of Comparison

| Aspect | Dry Process | Wet Process |

|---|---|---|

| Definition | Chemical manufacturing using dry raw materials with minimal liquid involvement. | Chemical manufacturing involving liquid solvents or water in the reaction or separation. |

| Typical Uses | Production of cement, ceramics, and some chemical powders. | Production of acids, alkalis, and chemical extraction processes. |

| Energy Consumption | Generally lower due to absence of drying steps. | Higher energy use because of evaporation and drying requirements. |

| Process Complexity | Simpler setup; less equipment needed. | More complex; requires handling of liquids and waste treatment. |

| Environmental Impact | Lower wastewater generation; less pollution risk. | Higher water use and wastewater generation, requiring treatment. |

| Product Quality | Consistent solid product with fewer impurities. | Better control over chemical composition and homogeneity. |

| Scale | Best suited for large-scale continuous production. | Flexible for batch processes and smaller scale. |

Introduction to Dry Process vs Wet Process

The dry process involves ripe coffee cherries being sun-dried and hulled, preserving fruity and sweet flavor profiles with lower acidity. The wet process, also known as washed processing, removes the cherry pulp using water fermentation, highlighting brightness and clarity in the coffee cup with higher acidity. Each method impacts bean quality, flavor complexity, and environmental resource use distinctly.

Understanding the Dry Process

The dry process in coffee production involves drying the whole coffee cherries under the sun, which naturally ferments the fruit's sugars and imparts a distinct fruity flavor profile. This method is more environmentally friendly and cost-effective, using less water compared to the wet process that requires extensive washing and fermentation tanks. Understanding the dry process helps you appreciate the unique characteristics and regional nuances of coffee beans produced through this traditional technique.

Key Steps in the Wet Process

The wet process involves key steps such as soaking ripe coffee cherries in water to ferment and loosen the mucilage, followed by thorough washing to remove the pulp. After washing, the beans are dried either in the sun or with mechanical dryers until they reach optimal moisture content. Your choice of wet processing enhances coffee quality by producing cleaner, brighter flavors.

Major Differences Between Dry and Wet Processes

Dry process involves roasting and grinding coffee beans without water, retaining natural flavors and offering a heavier body, whereas wet process uses water to ferment and wash beans, resulting in cleaner, brighter taste profiles. Dry processed beans typically have higher sugar content due to longer drying times, while wet processed beans exhibit more acidity and consistent quality. The wet process requires more water and infrastructure but yields beans with reduced defects compared to the simpler, more traditional dry method.

Advantages of the Dry Process

The dry process offers significant water savings, making it ideal for regions facing water scarcity. It reduces operational costs by eliminating the need for water treatment and wastewater management. Energy consumption is typically lower compared to the wet process, enhancing overall sustainability in industrial production.

Benefits of the Wet Process

The wet process, also known as the washed process, offers superior coffee bean quality by removing fruit residues and reducing defects, resulting in cleaner, brighter flavors and enhanced acidity. This method promotes consistency in bean size and density, which supports uniform roasting and improves overall cup quality. Your coffee experiences a fresher and more refined taste, making the wet process a preferred choice for specialty coffee production.

Applications and Industries Using Each Process

The dry process is primarily utilized in cement manufacturing and mineral extraction industries due to its energy efficiency and suitability for processing raw materials with low moisture content. The wet process is favored in industries such as ceramics, pharmaceuticals, and metal refining where fine particle dispersion and precise chemical mixing are essential. Understanding these applications helps you select the appropriate method tailored to your industrial requirements and product specifications.

Cost Comparison: Dry Process vs Wet Process

The dry process generally incurs lower operational costs due to reduced water usage and simpler equipment requirements, making it more economical for regions with limited water resources. In contrast, the wet process demands higher investment in water treatment and energy consumption, driving up overall expenses despite its superior coffee bean quality and more consistent flavor profile. Cost-effectiveness depends on factors such as local water availability, scale of production, and desired coffee quality standards.

Environmental Impact of Both Processes

The dry process for coffee production generates significantly less wastewater compared to the wet process, reducing aquatic pollution risks. However, it often leads to higher dust emissions and requires extensive land use for drying, which can contribute to deforestation and soil degradation. The wet process consumes large volumes of water and produces effluents rich in organic matter, demanding effective wastewater treatment to mitigate environmental contamination.

Choosing the Right Process for Your Needs

Selecting the right coffee processing method depends on factors such as flavor profile, resource availability, and environmental conditions. The dry process, ideal for regions with limited water access, produces fruitier, heavier-bodied beans, while the wet process offers cleaner, brighter flavors but requires substantial water and infrastructure. Evaluating your desired taste outcome, budget, and sustainability goals will guide the optimal choice between dry and wet processing methods.

dry process vs wet process Infographic

libmatt.com

libmatt.com