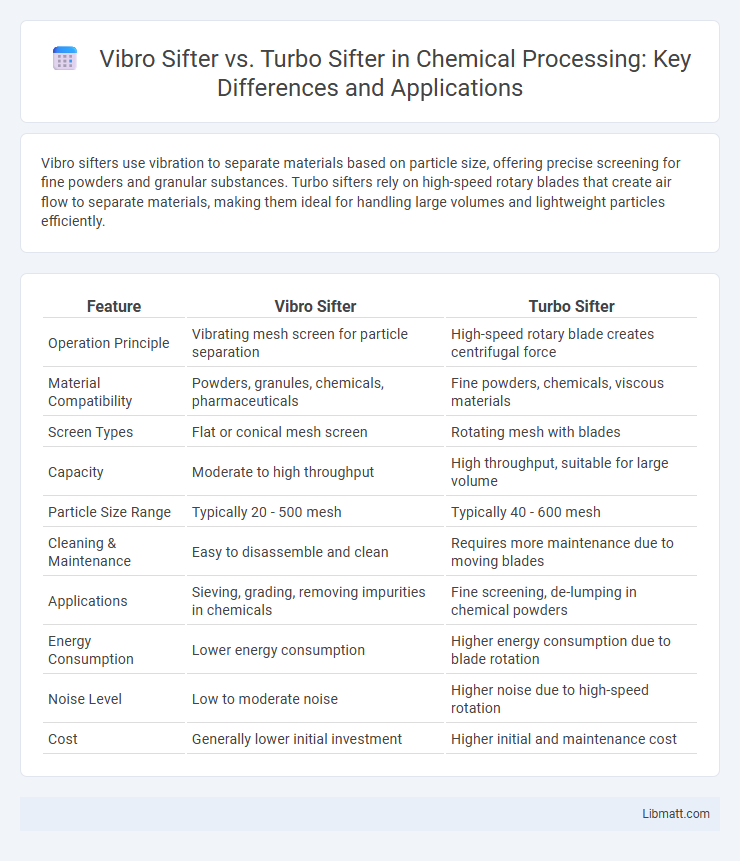

Vibro sifters use vibration to separate materials based on particle size, offering precise screening for fine powders and granular substances. Turbo sifters rely on high-speed rotary blades that create air flow to separate materials, making them ideal for handling large volumes and lightweight particles efficiently.

Table of Comparison

| Feature | Vibro Sifter | Turbo Sifter |

|---|---|---|

| Operation Principle | Vibrating mesh screen for particle separation | High-speed rotary blade creates centrifugal force |

| Material Compatibility | Powders, granules, chemicals, pharmaceuticals | Fine powders, chemicals, viscous materials |

| Screen Types | Flat or conical mesh screen | Rotating mesh with blades |

| Capacity | Moderate to high throughput | High throughput, suitable for large volume |

| Particle Size Range | Typically 20 - 500 mesh | Typically 40 - 600 mesh |

| Cleaning & Maintenance | Easy to disassemble and clean | Requires more maintenance due to moving blades |

| Applications | Sieving, grading, removing impurities in chemicals | Fine screening, de-lumping in chemical powders |

| Energy Consumption | Lower energy consumption | Higher energy consumption due to blade rotation |

| Noise Level | Low to moderate noise | Higher noise due to high-speed rotation |

| Cost | Generally lower initial investment | Higher initial and maintenance cost |

Introduction to Vibro Sifter and Turbo Sifter

Vibro sifters utilize vibration to separate materials by size, featuring a circular screening surface that efficiently sorts powders and granules in industries like pharmaceuticals and food processing. Turbo sifters rely on a high-speed rotary motion to accelerate materials through the mesh, delivering rapid screening suitable for fine powders and high-capacity applications. Both machines enhance product quality by removing impurities, but differ in screening mechanism and operational speed.

Principle of Operation: Vibro Sifter vs Turbo Sifter

Vibro sifters operate using high-frequency vibrations transmitted through a motor to a screen, causing material to stratify and pass through specific mesh sizes efficiently. Turbo sifters rely on centrifugal force generated by rapidly rotating blades inside a cylindrical screen, accelerating the separation of particles by size. Understanding these principles helps you select the best sifting technology for consistent material processing and optimal particle classification.

Key Differences in Design

Vibro sifters use a circular vibrating motion generated by unbalanced motors, providing gentle and uniform screening ideal for delicate materials. Turbo sifters employ a high-speed rotary motion with fixed pleated screens, offering rapid separation suited for fine powders and high-capacity operations. Your choice depends on the desired screening efficiency, material characteristics, and throughput requirements.

Material Compatibility and Applications

Vibro sifters excel in handling delicate and heat-sensitive materials such as pharmaceuticals, food powders, and chemicals due to their gentle vibration mechanism, ensuring minimal product degradation. Turbo sifters are designed for high-capacity screening of coarse and granular substances like plastics, pigments, and chemicals, offering rapid separation with robust material handling capabilities. Both sifters serve critical roles in industries requiring precise particle size separation but differ significantly in material compatibility based on their operational dynamics.

Performance and Efficiency Comparison

Vibro sifters provide high precision and consistent particle separation through linear or circular vibrating motion, making them ideal for fine powders and granular materials with minimal contamination. Turbo sifters utilize high-speed rotary motion to achieve rapid screening and separation, offering faster throughput but potentially higher wear and lower finesse for delicate products. In terms of performance and efficiency, vibro sifters excel in accuracy and gentle handling, while turbo sifters are better suited for bulk processing where speed is prioritized over screening precision.

Particle Size Separation Capabilities

Vibro sifters provide precise particle size separation through controlled vibration, allowing effective classification of fine and medium powders in pharmaceutical and food industries. Turbo sifters utilize high-speed rotary motion for rapid separation, efficiently processing bulk materials with a wider particle size range but less precision for very fine powders. The choice between vibro and turbo sifters depends on the required particle size distribution accuracy and material handling capacity.

Ease of Cleaning and Maintenance

Vibro sifters feature a simple, open frame design and fewer components, enabling quicker disassembly and easier access for thorough cleaning, which reduces downtime in production. Turbo sifters have more intricate multi-deck configurations and enclosed structures that may require specialized tools and longer cleaning cycles for effective maintenance. Choosing a vibro sifter enhances operational efficiency in industries demanding frequent cleaning, such as pharmaceuticals and food processing.

Energy Consumption and Noise Levels

Vibro sifters generally consume less energy due to their efficient vibration motor system, making them suitable for continuous operations with lower power costs. Turbo sifters tend to have higher energy consumption because of their more powerful airflow mechanisms required to achieve high-speed separation. Noise levels in vibro sifters are significantly lower as they rely on gentle vibrations, whereas turbo sifters produce louder operational noise from the high-velocity air streams and motor activity.

Cost Considerations and ROI

Vibro sifters typically have lower initial purchase and maintenance costs compared to turbo sifters, making them more budget-friendly for small to medium-scale operations. Turbo sifters, while more expensive upfront, provide higher screening efficiency and throughput, often resulting in faster return on investment (ROI) for large-scale industrial applications. Evaluating total cost of ownership, including energy consumption and downtime, is crucial to determine which sifting technology delivers the best ROI for specific production needs.

Which Sifter is Ideal for Your Process?

Choosing the ideal sifter depends on your process needs: a vibro sifter offers precise particle separation with gentle vibration, perfect for delicate materials and fine powders, while a turbo sifter delivers aggressive multi-directional action suitable for high-capacity screening and high-moisture content materials. Consider the material characteristics, required throughput, and screening efficiency to determine which technology enhances your productivity and product quality. Your process benefits most from matching the sifter's mechanical action and capacity to your specific material properties and operational demands.

Vibro sifter vs turbo sifter Infographic

libmatt.com

libmatt.com