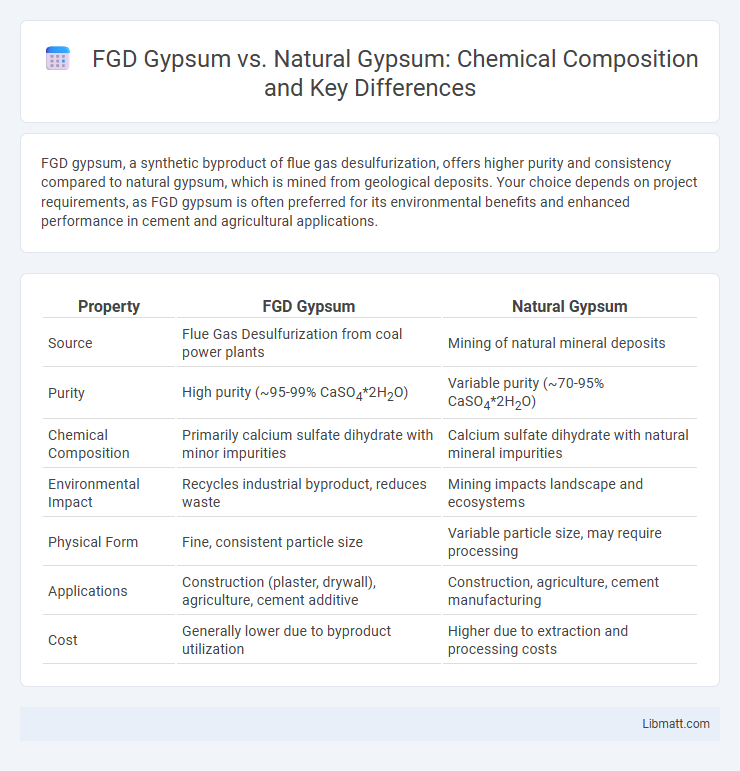

FGD gypsum, a synthetic byproduct of flue gas desulfurization, offers higher purity and consistency compared to natural gypsum, which is mined from geological deposits. Your choice depends on project requirements, as FGD gypsum is often preferred for its environmental benefits and enhanced performance in cement and agricultural applications.

Table of Comparison

| Property | FGD Gypsum | Natural Gypsum |

|---|---|---|

| Source | Flue Gas Desulfurization from coal power plants | Mining of natural mineral deposits |

| Purity | High purity (~95-99% CaSO4*2H2O) | Variable purity (~70-95% CaSO4*2H2O) |

| Chemical Composition | Primarily calcium sulfate dihydrate with minor impurities | Calcium sulfate dihydrate with natural mineral impurities |

| Environmental Impact | Recycles industrial byproduct, reduces waste | Mining impacts landscape and ecosystems |

| Physical Form | Fine, consistent particle size | Variable particle size, may require processing |

| Applications | Construction (plaster, drywall), agriculture, cement additive | Construction, agriculture, cement manufacturing |

| Cost | Generally lower due to byproduct utilization | Higher due to extraction and processing costs |

Introduction to Gypsum Types

FGD gypsum, produced from flue gas desulfurization in power plants, offers high purity and consistent quality compared to natural gypsum, which is mined from geological deposits. Natural gypsum contains varying mineral impurities that can affect its performance in construction and agriculture applications. The controlled chemical composition of FGD gypsum enhances its suitability for producing drywall, cement additives, and soil conditioners.

What is FGD Gypsum?

FGD gypsum is a synthetic byproduct produced from flue gas desulfurization, a process that removes sulfur dioxide from power plant emissions. It possesses a similar chemical composition to natural gypsum, primarily calcium sulfate dihydrate, making it suitable for applications in cement manufacturing, agriculture, and wallboard production. Unlike natural gypsum, which is mined from sedimentary rock deposits, FGD gypsum is environmentally beneficial by recycling industrial waste and reducing reliance on mining.

What is Natural Gypsum?

Natural gypsum is a mineral composed primarily of calcium sulfate dihydrate, formed through the evaporation of seawater in sedimentary environments. It is mined directly from geological deposits and used extensively in construction, agriculture, and industrial applications due to its high purity and consistent chemical composition. Unlike synthetic gypsum, natural gypsum contains minimal impurities, making it ideal for producing high-quality drywall and cement products.

Chemical Composition Comparison

FGD gypsum primarily consists of calcium sulfate dihydrate (CaSO4*2H2O) similar to natural gypsum but often contains higher levels of impurities such as unreacted lime and trace heavy metals from flue gas desulfurization processes. Natural gypsum has a more consistent chemical composition with fewer contaminants, predominantly pure calcium sulfate with minor amounts of other elements like silica and clay minerals. The purity difference affects its suitability for specific industrial applications, with FGD gypsum requiring additional processing to meet quality standards comparable to natural gypsum.

Physical Properties Differences

FGD gypsum, produced from flue gas desulfurization, typically has a finer particle size and higher purity compared to natural gypsum, which contains more impurities like clay and sand. The density and hardness of FGD gypsum are more uniform, enhancing its workability in cement and plaster applications. Your choice between FGD gypsum and natural gypsum can affect the strength and smoothness of the final building materials due to these key physical property differences.

Environmental Impact: FGD vs Natural Gypsum

FGD gypsum, a byproduct of flue gas desulfurization in power plants, significantly reduces industrial waste and lowers landfill use compared to natural gypsum, which is mined directly from the earth, leading to habitat disruption and resource depletion. Utilizing FGD gypsum promotes recycling of industrial emissions, thereby minimizing greenhouse gas emissions and soil contamination associated with traditional gypsum extraction. Your choice of FGD gypsum supports sustainable construction practices with a smaller environmental footprint than natural gypsum mining.

Industrial Applications of Both Types

FGD gypsum, a byproduct of flue gas desulfurization in power plants, is widely used in cement production, wallboard manufacturing, and soil stabilization due to its fine particle size and high purity. Natural gypsum, formed through sedimentary processes, is primarily utilized in agriculture as a soil amendment, in construction for plaster and drywall, and in the manufacturing of cement and fertilizers. Both types of gypsum serve crucial roles in industrial applications, with FGD gypsum offering sustainable alternatives in environmentally friendly building materials and natural gypsum providing essential nutrients and structural components.

Cost and Availability Analysis

FGD gypsum is often more cost-effective than natural gypsum due to its status as a byproduct from flue gas desulfurization processes, reducing extraction and transportation expenses. Natural gypsum availability depends heavily on mining operations, which can be limited and more expensive due to geographic and environmental factors. Your choice between FGD gypsum and natural gypsum should consider local supply stability and budget constraints to optimize project costs.

Regulatory and Safety Considerations

FGD gypsum, derived from flue gas desulfurization processes, typically meets stringent environmental regulations due to its controlled industrial origin, often requiring compliance with EPA and OSHA standards. Natural gypsum, while generally considered safe, may contain impurities or naturally occurring radioactive materials that necessitate careful monitoring and adherence to local mining safety regulations. Both materials demand proper handling and storage to mitigate dust hazards and environmental impact per regulatory guidelines.

Future Trends in Gypsum Usage

FGD gypsum, a byproduct of flue gas desulfurization in power plants, is gaining significant traction as a sustainable alternative to natural gypsum due to its high purity and availability. Advances in processing technologies are enhancing the quality and usability of FGD gypsum for construction materials, promoting circular economy practices. The growing emphasis on environmental regulations and resource conservation is expected to drive increased adoption of FGD gypsum in the global gypsum market.

FGD gypsum vs natural gypsum Infographic

libmatt.com

libmatt.com