Upflow reactors promote better gas-liquid contact by forcing the fluid upward through the medium, enhancing mass transfer and reducing clogging risks compared to downflow reactors where fluids move downward, potentially causing channeling and uneven distribution. Your choice depends on process requirements like solids handling, phase separation, and maintenance preferences for optimal reactor performance.

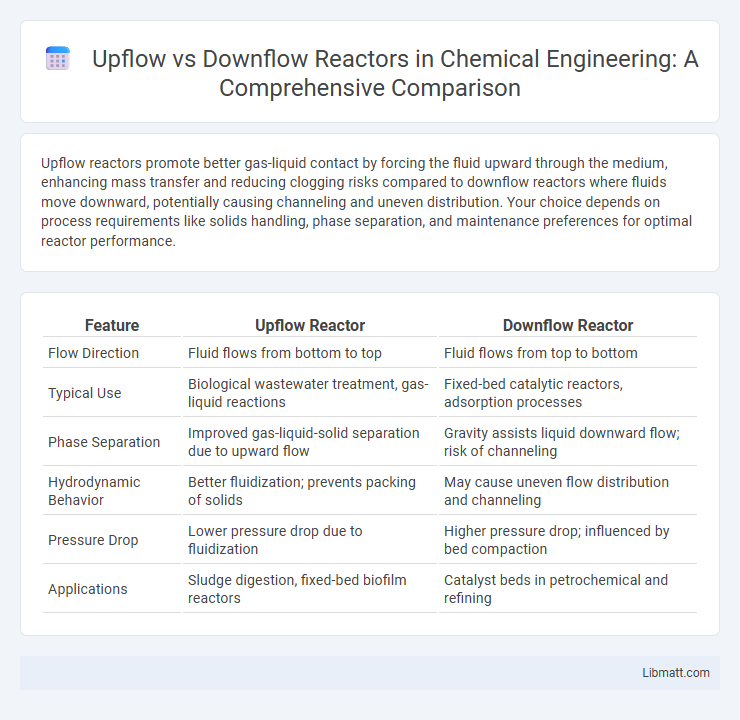

Table of Comparison

| Feature | Upflow Reactor | Downflow Reactor |

|---|---|---|

| Flow Direction | Fluid flows from bottom to top | Fluid flows from top to bottom |

| Typical Use | Biological wastewater treatment, gas-liquid reactions | Fixed-bed catalytic reactors, adsorption processes |

| Phase Separation | Improved gas-liquid-solid separation due to upward flow | Gravity assists liquid downward flow; risk of channeling |

| Hydrodynamic Behavior | Better fluidization; prevents packing of solids | May cause uneven flow distribution and channeling |

| Pressure Drop | Lower pressure drop due to fluidization | Higher pressure drop; influenced by bed compaction |

| Applications | Sludge digestion, fixed-bed biofilm reactors | Catalyst beds in petrochemical and refining |

Introduction to Upflow and Downflow Reactors

Upflow reactors direct fluid flow from the bottom to the top, promoting better contact between phases and improving solids suspension, which enhances treatment efficiency in biological and chemical processes. Downflow reactors allow fluid to move downward, utilizing gravity to aid phase separation and improve residence time distribution, making them ideal for sedimentation and filtration applications. Understanding your process needs helps determine which reactor design--upflow or downflow--optimizes reaction kinetics and operational performance.

Working Principles of Upflow Reactors

Upflow reactors operate by introducing the influent at the bottom, allowing the fluid to flow upward through the packed bed or biological media, which enhances contact between the substrate and microorganisms. This upward flow design prevents clogging by suspending solids, promoting better biomass retention and uniform distribution of reactants. The counter-current movement of gas or liquid phases in some upflow reactors further improves mass transfer efficiency and reaction rates.

Mechanisms of Downflow Reactors

Downflow reactors operate by directing the reactant fluids downward through the catalyst bed, utilizing gravity to facilitate uniform contact and enhanced mass transfer. The mechanism involves liquid and gas phases flowing concurrently or countercurrently, promoting efficient reaction kinetics and minimizing channeling or bypassing. This flow pattern improves catalyst utilization, reduces pressure drop, and supports effective heat management in processes such as hydrodesulfurization and catalytic cracking.

Key Design Differences

Upflow reactors feature influent entering at the bottom and moving upward, promoting better gas-liquid-solid contact and preventing clogging in wastewater treatment. Downflow reactors allow influent to flow downward through the media, utilizing gravity for improved contact time and sedimentation. Your choice between upflow and downflow reactors depends on factors like solid loading, gas production, and desired retention times.

Comparative Performance in Wastewater Treatment

Upflow reactors enhance wastewater treatment by promoting better contact between wastewater and biomass through upward flow, resulting in improved solids retention and higher organic removal efficiency compared to downflow reactors. Downflow reactors offer advantages in simpler design and lower operational complexity but may experience clogging and channeling issues that reduce treatment performance. Studies indicate upflow configurations typically achieve superior chemical oxygen demand (COD) removal and biomass activity, making them more effective for high-strength industrial wastewater treatment.

Operational Advantages of Upflow Reactors

Upflow reactors offer superior solids handling and reduced clogging risks by moving influent upward, enhancing contact between wastewater and biomass, which improves treatment efficiency. Your system benefits from better gas-liquid-solid separation, leading to lower energy consumption and easier sludge removal compared to downflow reactors. These operational advantages make upflow reactors ideal for wastewater treatment processes requiring stable performance and reduced maintenance.

Benefits and Limitations of Downflow Reactors

Downflow reactors provide improved contact between gases and liquids, enhancing mass transfer efficiency essential in processes like wastewater treatment and catalytic reactions. Their design reduces channeling and promotes uniform flow distribution, resulting in stable operation and predictable performance. However, downflow reactors can experience limitations such as increased pressure drop and potential clogging in particulate-laden streams, which may require additional maintenance to ensure optimal functionality for your industrial applications.

Energy Efficiency Comparison

Upflow reactors typically exhibit higher energy efficiency compared to downflow reactors due to improved gas-liquid contact and reduced pressure drop, leading to lower operational costs. In downflow reactors, the gravitational force assists fluid movement, but energy consumption can increase because of higher pumping requirements to maintain flow rates. Your choice between the two should consider specific process conditions, as upflow reactors often optimize energy use in treatment or catalytic applications by enhancing mass transfer rates.

Suitability for Various Industrial Applications

Upflow reactors excel in wastewater treatment and biogas production due to their efficient gas-liquid-solid contact, making them ideal for industries requiring high biomass retention and low clogging risk. Downflow reactors are suitable for chemical synthesis and catalytic processes where gravity aids in phase separation and better control of residence time, enhancing reaction efficiency. Your choice between upflow and downflow reactors depends on the specific industrial process requirements, including reaction type, phase behavior, and desired throughput.

Future Trends in Reactor Technology

Future trends in reactor technology emphasize the integration of digital twin models and advanced process controls to optimize both upflow and downflow reactors. Innovations in catalyst design and materials enhance mass transfer and reduce fouling in upflow reactors, while downflow reactors benefit from improved residence time distribution and energy efficiency. The shift towards sustainable chemical processes drives the adoption of hybrid reactor systems combining upflow and downflow configurations for maximum conversion and selectivity.

Upflow reactor vs downflow reactor Infographic

libmatt.com

libmatt.com