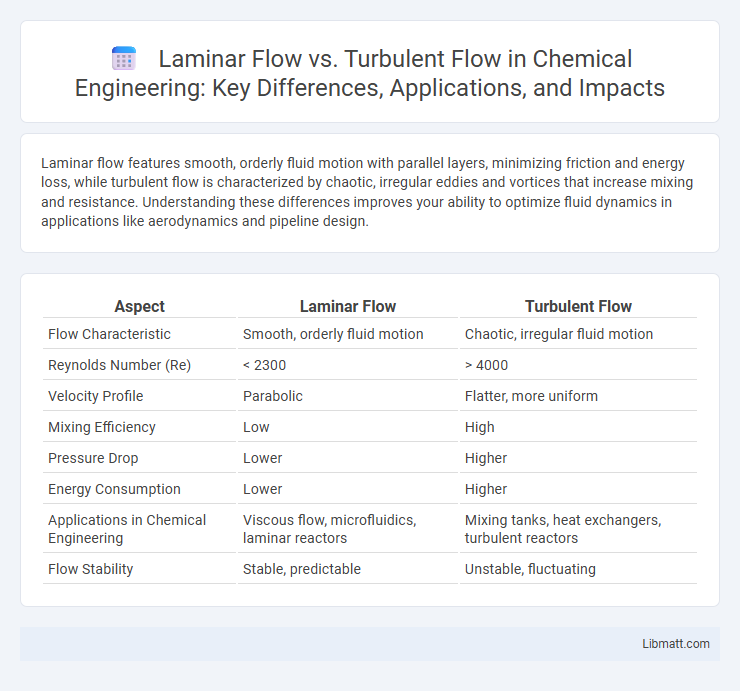

Laminar flow features smooth, orderly fluid motion with parallel layers, minimizing friction and energy loss, while turbulent flow is characterized by chaotic, irregular eddies and vortices that increase mixing and resistance. Understanding these differences improves your ability to optimize fluid dynamics in applications like aerodynamics and pipeline design.

Table of Comparison

| Aspect | Laminar Flow | Turbulent Flow |

|---|---|---|

| Flow Characteristic | Smooth, orderly fluid motion | Chaotic, irregular fluid motion |

| Reynolds Number (Re) | < 2300 | > 4000 |

| Velocity Profile | Parabolic | Flatter, more uniform |

| Mixing Efficiency | Low | High |

| Pressure Drop | Lower | Higher |

| Energy Consumption | Lower | Higher |

| Applications in Chemical Engineering | Viscous flow, microfluidics, laminar reactors | Mixing tanks, heat exchangers, turbulent reactors |

| Flow Stability | Stable, predictable | Unstable, fluctuating |

Introduction to Fluid Flow Dynamics

Laminar flow occurs when a fluid moves in smooth, parallel layers with minimal mixing, resulting in low Reynolds numbers typically below 2,300. Turbulent flow is characterized by chaotic fluid motion and mixing, occurring at higher Reynolds numbers above 4,000, causing increased friction and energy loss. Understanding these distinct fluid flow regimes is essential for optimizing Your systems in engineering, aerodynamics, and pipeline design.

Defining Laminar Flow

Laminar flow is characterized by smooth, orderly fluid motion where layers of fluid slide past one another with minimal mixing, typically occurring at low Reynolds numbers below 2,300. It is dominated by viscous forces, resulting in predictable velocity profiles and reduced frictional losses in applications such as pipe flow and aerodynamic surfaces. Understanding laminar flow behavior is essential for optimizing fluid transport efficiency and minimizing energy consumption in engineering systems.

Characteristics of Turbulent Flow

Turbulent flow is characterized by chaotic, irregular fluid motion with eddies and vortices that enhance mixing and momentum transfer. It exhibits higher Reynolds numbers, typically exceeding 4000, indicating a dominance of inertial forces over viscous forces. Understanding turbulent flow helps you optimize fluid dynamics in engineering applications such as pipeline design, aerospace, and environmental systems.

Key Differences Between Laminar and Turbulent Flow

Laminar flow is characterized by smooth, parallel layers of fluid with minimal mixing, resulting in predictable velocity profiles and low Reynolds numbers typically below 2,300. Turbulent flow features chaotic fluid motion with eddies and vortices, higher Reynolds numbers above 4,000, and enhanced mixing that increases momentum and heat transfer rates. Understanding these differences helps you optimize fluid dynamics in engineering applications, such as pipeline design and aerodynamic efficiency.

Factors Influencing Flow Type

Flow type, whether laminar or turbulent, depends primarily on fluid velocity, viscosity, and characteristic length, quantified by the Reynolds number. Low Reynolds numbers indicate laminar flow with smooth, orderly layers, while high Reynolds numbers lead to turbulent flow characterized by chaotic and irregular fluid motion. Surface roughness and flow disturbances also influence the transition between laminar and turbulent regimes in practical applications.

Reynolds Number and Flow Transition

Reynolds Number is a dimensionless value used to predict flow regimes in fluid dynamics, indicating whether flow is laminar or turbulent based on velocity, characteristic length, and kinematic viscosity. Laminar flow occurs at low Reynolds Numbers, typically below 2,300, where fluid moves in smooth, orderly layers, whereas turbulent flow arises at high Reynolds Numbers, generally above 4,000, characterized by chaotic and irregular fluid motion. The flow transition zone between Reynolds Numbers 2,300 and 4,000 marks the shift from stable laminar patterns to unpredictable turbulence, significantly affecting pressure drop and heat transfer rates.

Applications of Laminar Flow

Laminar flow is critical in applications requiring precise fluid control and minimal disturbance, such as in medical devices, chemical processing, and HVAC systems. Its smooth, orderly movement reduces friction and contamination risk, making it ideal for cleanrooms and laboratory environments. You benefit from enhanced efficiency and accuracy when utilizing systems designed to maintain laminar flow conditions.

Applications of Turbulent Flow

Turbulent flow is essential in industrial mixers, heat exchangers, and combustion engines where rapid mixing and efficient heat transfer are required. This chaotic fluid motion enhances mass and momentum transfer, improving chemical reactions and cooling processes in power plants and turbines. Understanding turbulent flow helps you optimize system designs for maximum performance and energy efficiency.

Advantages and Disadvantages of Each Flow

Laminar flow offers advantages such as smooth, predictable fluid motion with minimal mixing and low friction losses, making it ideal for precise control in applications like microfluidics and aerodynamic testing. Its disadvantage lies in limited mixing and lower momentum transfer, which can reduce heat and mass transfer efficiency compared to turbulent flow. Turbulent flow provides enhanced mixing, higher heat transfer rates, and better momentum exchange, but it also results in increased energy loss due to friction and more complex, less predictable fluid behavior, which can complicate system design and maintenance.

Conclusion: Choosing the Right Flow for Your Application

Selecting between laminar flow and turbulent flow depends on your specific application needs, such as precision, mixing, or heat transfer efficiency. Laminar flow offers smooth, predictable fluid movement ideal for sensitive experiments or processes requiring minimal disturbance. Turbulent flow enhances mixing and heat transfer, making it suitable for industrial applications where rapid blending and temperature uniformity are critical.

laminar flow vs turbulent flow Infographic

libmatt.com

libmatt.com