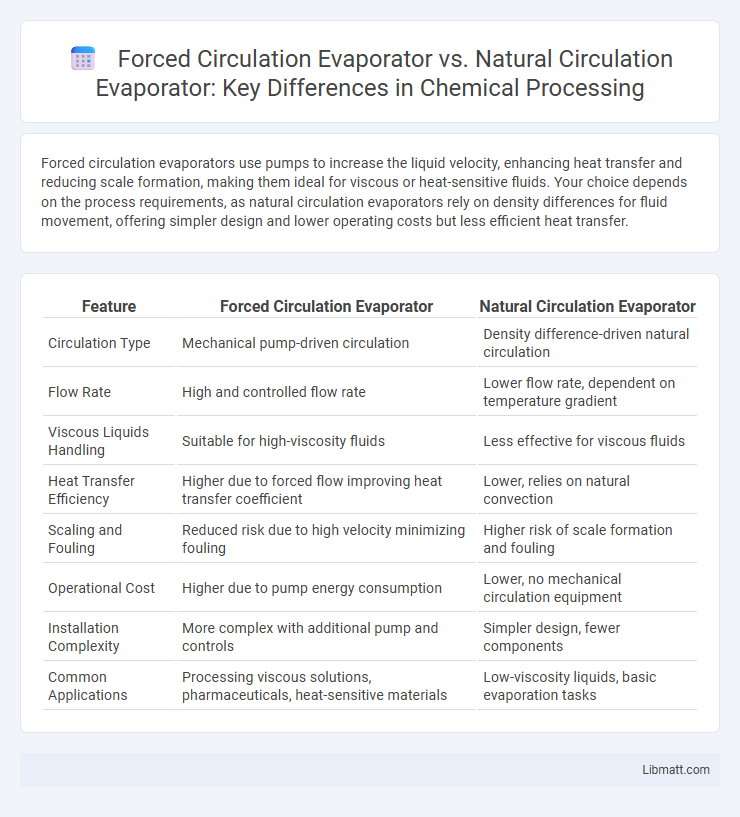

Forced circulation evaporators use pumps to increase the liquid velocity, enhancing heat transfer and reducing scale formation, making them ideal for viscous or heat-sensitive fluids. Your choice depends on the process requirements, as natural circulation evaporators rely on density differences for fluid movement, offering simpler design and lower operating costs but less efficient heat transfer.

Table of Comparison

| Feature | Forced Circulation Evaporator | Natural Circulation Evaporator |

|---|---|---|

| Circulation Type | Mechanical pump-driven circulation | Density difference-driven natural circulation |

| Flow Rate | High and controlled flow rate | Lower flow rate, dependent on temperature gradient |

| Viscous Liquids Handling | Suitable for high-viscosity fluids | Less effective for viscous fluids |

| Heat Transfer Efficiency | Higher due to forced flow improving heat transfer coefficient | Lower, relies on natural convection |

| Scaling and Fouling | Reduced risk due to high velocity minimizing fouling | Higher risk of scale formation and fouling |

| Operational Cost | Higher due to pump energy consumption | Lower, no mechanical circulation equipment |

| Installation Complexity | More complex with additional pump and controls | Simpler design, fewer components |

| Common Applications | Processing viscous solutions, pharmaceuticals, heat-sensitive materials | Low-viscosity liquids, basic evaporation tasks |

Introduction to Evaporation Systems

Forced circulation evaporators use pumps to circulate the liquid rapidly through the heating tubes, enhancing heat transfer and preventing fouling. Natural circulation evaporators rely on density differences created by heating to circulate the liquid without mechanical assistance, making them suitable for simpler and lower viscosity solutions. Understanding the differences in circulation methods helps you select the appropriate evaporation system for efficient concentration and heat management in industrial processes.

Overview of Forced Circulation Evaporators

Forced circulation evaporators utilize pumps to circulate the liquid rapidly through the heating tubes, ensuring high heat transfer rates and preventing fouling or scaling. These evaporators are ideal for viscous, heat-sensitive, or crystallizing liquids because the forced flow reduces temperature gradients and improves evaporation efficiency. The controlled circulation allows better handling of volatile substances and precise temperature management compared to natural circulation systems.

Overview of Natural Circulation Evaporators

Natural circulation evaporators use the density difference between the heated liquid and cooler liquid to create a natural flow without the need for pumps, making them energy-efficient and low-maintenance. These evaporators are suitable for applications with moderate capacity and where the fluid has low viscosity and minimal fouling tendencies. Your choice of a natural circulation evaporator can enhance process reliability and reduce operational costs in systems with stable flow and temperature conditions.

Working Principles: Forced vs. Natural Circulation

Forced circulation evaporators utilize pumps to actively circulate the liquid through the heating surface, ensuring uniform temperature distribution and higher heat transfer efficiency. Natural circulation evaporators rely on the density difference between the hot and cold liquid to drive the circulation without mechanical assistance. Your choice depends on factors like fluid properties and energy efficiency, with forced circulation offering better control for viscous or heat-sensitive liquids.

Key Design Differences

Forced circulation evaporators utilize a pump to maintain high fluid velocity, preventing fouling and improving heat transfer efficiency through turbulent flow, while natural circulation evaporators rely on the density difference between hot and cold liquid for circulation, resulting in lower flow rates and simpler design. The forced circulation system supports higher viscosity or heat-sensitive liquids and is generally used in larger-scale operations, whereas natural circulation evaporators are favored for their lower operational costs and less complex construction. Your choice depends on the nature of the fluid, desired thermal performance, and maintenance considerations.

Energy Efficiency Comparison

Forced circulation evaporators demonstrate higher energy efficiency than natural circulation evaporators due to their enhanced heat transfer rates driven by mechanical pumping, which reduces fouling and improves heat exchanger performance. The consistent fluid velocity in forced circulation systems minimizes temperature gradients, leading to lower steam consumption per unit of evaporated water compared to natural circulation evaporators relying on buoyancy-induced flow. Industrial energy audits report up to 15-20% energy savings in forced circulation setups, making them ideal for processes requiring rapid and uniform heat transfer.

Maintenance and Operational Considerations

Forced circulation evaporators require regular maintenance of pumps and sealing systems to ensure consistent fluid flow and prevent downtime, while natural circulation evaporators benefit from simpler designs with fewer mechanical parts, reducing maintenance frequency. Operationally, forced circulation systems offer improved heat transfer efficiency and better handling of viscous liquids, but they demand continuous monitoring of pump performance and potential clogging. Your choice depends on balancing maintenance resources with operational efficiency and process reliability.

Applications in Industry

Forced circulation evaporators are widely used in industries requiring high heat transfer rates and handling viscous or heat-sensitive fluids, such as food processing, chemical manufacturing, and pharmaceuticals. Natural circulation evaporators are preferable for applications with lower viscosity liquids and where simplicity and lower operating costs are prioritized, commonly seen in sugar refining, desalination, and wastewater treatment. Your choice depends on the specific process conditions, fluid properties, and the need for efficient heat transfer or gentle handling of products.

Advantages and Limitations of Each System

Forced circulation evaporators offer superior heat transfer efficiency and precise control over fluid flow, making them ideal for handling viscous or heat-sensitive liquids without the risk of scaling or fouling. Natural circulation evaporators rely on density differences to circulate liquid, resulting in lower operational costs and simpler design but face limitations in handling high-viscosity fluids and maintaining consistent heat transfer rates. While forced circulation systems require higher energy input due to pumps, natural circulation systems may suffer from reduced evaporation capacity and potential for uneven temperature distribution.

Choosing the Right Evaporator for Your Process

Choosing the right evaporator for your process depends on factors like heating efficiency, fluid properties, and maintenance requirements. Forced circulation evaporators use pumps to enhance heat transfer, making them ideal for viscous or heat-sensitive liquids, while natural circulation evaporators rely on density differences to circulate fluid, offering simpler operation and lower energy consumption. Your selection should balance process complexity, fluid characteristics, and energy costs to optimize performance and longevity.

Forced circulation evaporator vs natural circulation evaporator Infographic

libmatt.com

libmatt.com