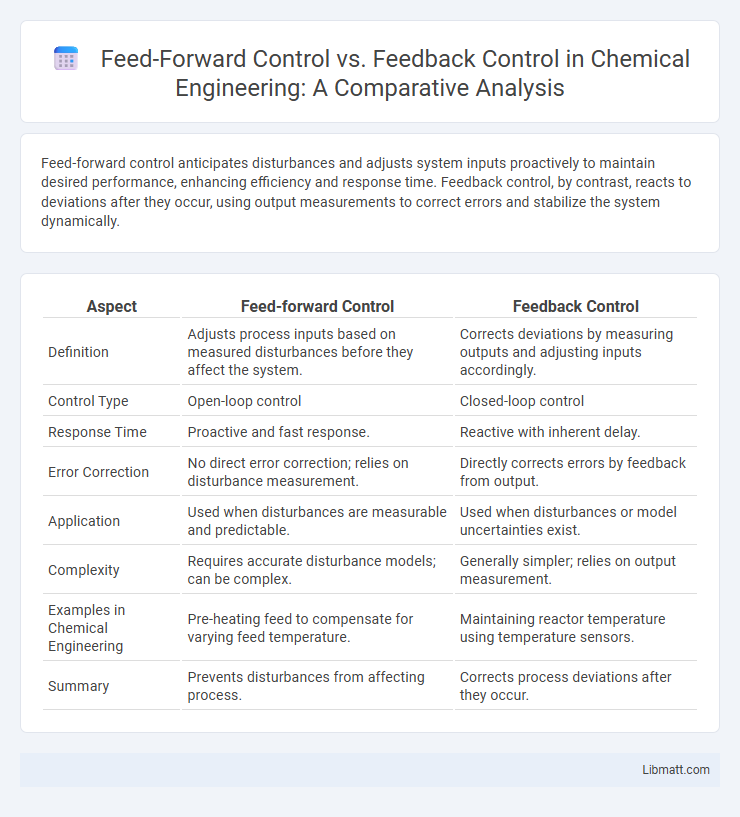

Feed-forward control anticipates disturbances and adjusts system inputs proactively to maintain desired performance, enhancing efficiency and response time. Feedback control, by contrast, reacts to deviations after they occur, using output measurements to correct errors and stabilize the system dynamically.

Table of Comparison

| Aspect | Feed-forward Control | Feedback Control |

|---|---|---|

| Definition | Adjusts process inputs based on measured disturbances before they affect the system. | Corrects deviations by measuring outputs and adjusting inputs accordingly. |

| Control Type | Open-loop control | Closed-loop control |

| Response Time | Proactive and fast response. | Reactive with inherent delay. |

| Error Correction | No direct error correction; relies on disturbance measurement. | Directly corrects errors by feedback from output. |

| Application | Used when disturbances are measurable and predictable. | Used when disturbances or model uncertainties exist. |

| Complexity | Requires accurate disturbance models; can be complex. | Generally simpler; relies on output measurement. |

| Examples in Chemical Engineering | Pre-heating feed to compensate for varying feed temperature. | Maintaining reactor temperature using temperature sensors. |

| Summary | Prevents disturbances from affecting process. | Corrects process deviations after they occur. |

Introduction to Control Systems

Feed-forward control predicts disturbances by using a model of the system to adjust inputs before deviations occur, enhancing system stability and reducing lag. Feedback control continuously monitors output variables and corrects errors by comparing actual performance with desired setpoints, ensuring accuracy despite unpredictable disturbances. Both control strategies are fundamental in control systems for maintaining desired operational conditions and improving overall system reliability.

What is Feed-Forward Control?

Feed-forward control is a proactive control strategy that anticipates disturbances and adjusts system inputs before errors occur, enhancing system stability and performance. It relies on predictive models and external measurements rather than detected output deviations, enabling timely corrections without waiting for feedback signals. This approach is particularly effective in processes with measurable disturbances and allows for faster response compared to traditional feedback control.

Understanding Feedback Control

Feedback control continuously monitors system output and compares it with the desired setpoint to correct deviations in real-time, ensuring stability and accuracy. It relies on sensors to detect errors and adjust inputs, making it essential in dynamic and unpredictable environments. Feedback control systems are widely used in applications like temperature regulation, speed control, and automated manufacturing processes.

Key Differences Between Feed-Forward and Feedback Control

Feed-forward control anticipates disturbances and adjusts system inputs proactively based on predictive models, whereas feedback control reacts to errors by correcting deviations after they occur. Feed-forward systems rely on accurate modeling and sensor data to prevent errors, while feedback systems depend on continuous monitoring of output to maintain desired performance. The primary difference lies in timing: feed-forward control acts before disturbance affects the system, feedback control acts after detecting deviation in output.

Advantages of Feed-Forward Control

Feed-forward control enhances system performance by anticipating disturbances before they affect the process, enabling faster corrective actions compared to feedback control which reacts after changes occur. This proactive approach improves accuracy and stability, reducing the likelihood of errors and minimizing system oscillations. Your operations benefit from increased efficiency and reduced downtime by implementing feed-forward control in dynamic environments.

Benefits of Feedback Control

Feedback control improves system stability by continuously monitoring outputs and making real-time adjustments to minimize errors or deviations from set points. It enhances accuracy and reliability in processes by automatically correcting disturbances and compensating for uncertainties. Your system benefits from increased robustness and adaptability, ensuring consistent performance even under varying conditions.

Limitations of Feed-Forward Control

Feed-forward control struggles with unpredicted disturbances and model inaccuracies, as it relies solely on preset inputs without real-time error correction. Its effectiveness diminishes when system dynamics change or external factors deviate from assumptions, leading to potential performance degradation. Unlike feedback control, feed-forward cannot compensate for unexpected variations, limiting its reliability in dynamic or uncertain environments.

Drawbacks of Feedback Control

Feedback control systems often experience delays because they react only after a deviation from the desired output occurs, which can lead to instability or oscillations. Measurement noise and sensor inaccuracies can degrade the performance and reliability of feedback control, causing erroneous corrective actions. You may find feed-forward control more effective in situations where predicting disturbances is possible, reducing reliance on delayed feedback responses.

Practical Applications of Both Control Strategies

Feed-forward control is widely used in manufacturing processes where anticipating disturbances ensures product quality, such as temperature regulation in chemical reactors. Feedback control dominates in robotics and automotive systems, continuously adjusting performance based on sensor data to maintain stability and accuracy. Combining both strategies enhances industrial automation by preempting issues while correcting deviations in real-time for optimal efficiency.

Choosing the Right Control Method for Your System

Selecting the appropriate control method depends on the system's dynamics and disturbance characteristics; feed-forward control excels in predictable environments by anticipating changes, while feedback control effectively corrects errors in systems with variable or unknown disturbances. Integration of both methods enhances overall system stability and performance, especially in complex or sensitive processes. Understanding the system's response time, noise levels, and control objectives guides the optimal balance between feed-forward and feedback control implementation.

Feed-forward control vs feedback control Infographic

libmatt.com

libmatt.com