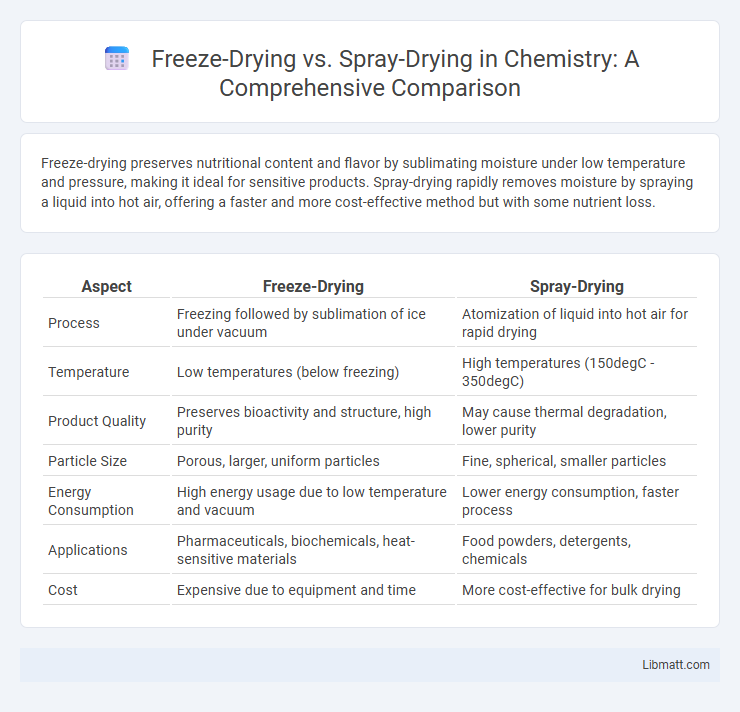

Freeze-drying preserves nutritional content and flavor by sublimating moisture under low temperature and pressure, making it ideal for sensitive products. Spray-drying rapidly removes moisture by spraying a liquid into hot air, offering a faster and more cost-effective method but with some nutrient loss.

Table of Comparison

| Aspect | Freeze-Drying | Spray-Drying |

|---|---|---|

| Process | Freezing followed by sublimation of ice under vacuum | Atomization of liquid into hot air for rapid drying |

| Temperature | Low temperatures (below freezing) | High temperatures (150degC - 350degC) |

| Product Quality | Preserves bioactivity and structure, high purity | May cause thermal degradation, lower purity |

| Particle Size | Porous, larger, uniform particles | Fine, spherical, smaller particles |

| Energy Consumption | High energy usage due to low temperature and vacuum | Lower energy consumption, faster process |

| Applications | Pharmaceuticals, biochemicals, heat-sensitive materials | Food powders, detergents, chemicals |

| Cost | Expensive due to equipment and time | More cost-effective for bulk drying |

Introduction to Freeze-Drying and Spray-Drying

Freeze-drying preserves food and pharmaceuticals by removing moisture through sublimation at low temperatures, maintaining product structure and nutritional value. Spray-drying rapidly converts liquids into powders by atomizing the substance into hot air, ideal for heat-sensitive materials requiring fast moisture removal. Your choice between these methods depends on the desired product quality, stability, and processing speed.

Principle of Freeze-Drying

Freeze-drying, also known as lyophilization, involves freezing the product and then reducing the surrounding pressure to allow the frozen water to sublimate directly from solid to gas. This process preserves the structural integrity and nutritional content of sensitive materials better than spray-drying, which uses heat that can degrade quality. Your choice between freeze-drying and spray-drying depends on the desired product stability, texture, and retention of bioactive compounds.

Principle of Spray-Drying

Spray-drying operates by atomizing a liquid feed into fine droplets that rapidly dry upon contact with hot air, transforming the liquid into a powder. This method preserves heat-sensitive compounds by minimizing exposure time to elevated temperatures and ensures consistent particle size distribution. Your choice of spray-drying can enhance product solubility and shelf-life while optimizing energy efficiency in industrial applications.

Key Differences in Process Mechanisms

Freeze-drying preserves product integrity by sublimating ice directly from frozen material under low pressure, maintaining molecular structure and minimizing thermal degradation. Spray-drying rapidly evaporates moisture by atomizing liquid feed into a hot air chamber, resulting in fine powders but with potential heat-induced changes. The distinct temperature and pressure conditions fundamentally affect product texture, stability, and shelf-life in both methods.

Product Quality and Stability Comparison

Freeze-drying preserves product quality by maintaining the original structure and nutrients, resulting in superior stability and longer shelf life compared to spray-drying. Spray-drying involves high temperatures that can degrade sensitive compounds, leading to reduced nutritional value and shorter stability. Your choice between these methods depends on the desired preservation of delicate ingredients and the target product's storage requirements.

Applications in the Food and Pharmaceutical Industries

Freeze-drying preserves the nutritional value and extends the shelf life of sensitive foods and pharmaceuticals by removing moisture under low temperature, making it ideal for probiotics, vaccines, and premium coffee. Spray-drying rapidly transforms liquid formulations into powders, commonly used for powdered milk, flavorings, and inhalable drugs due to its cost-efficiency and scalability. Your choice depends on whether maintaining molecular integrity or production speed and cost-efficiency is the priority in your food or pharmaceutical application.

Energy Efficiency and Cost Analysis

Freeze-drying typically consumes more energy than spray-drying due to its prolonged low-temperature vacuum process, leading to higher operational costs. Spray-drying offers greater cost efficiency with faster drying cycles and lower energy usage, making it preferable for large-scale production. However, freeze-drying's superior product quality justifies its expense in applications requiring high preservation of bioactive compounds.

Impact on Nutrient Retention and Flavor

Freeze-drying preserves nutrient retention and flavor more effectively than spray-drying by operating at lower temperatures, minimizing heat-induced degradation of vitamins and volatile compounds. Spray-drying exposes products to high temperatures, often resulting in significant losses of heat-sensitive nutrients and altered flavor profiles due to Maillard reactions and oxidation. Consequently, freeze-drying is preferred for preserving delicate bioactive compounds and maintaining the original taste of fruits, vegetables, and dairy products.

Environmental Considerations and Sustainability

Freeze-drying consumes significantly more energy due to its low-temperature vacuum process, impacting environmental sustainability compared to spray-drying, which operates at higher temperatures and is generally more energy-efficient. Spray-drying allows for continuous processing and lower water usage, reducing its overall carbon footprint and resource consumption. However, freeze-drying better preserves product quality and shelf life, potentially decreasing food waste and contributing to long-term environmental benefits.

Choosing the Right Drying Method

Choosing the right drying method depends on your product's sensitivity and intended use; freeze-drying preserves heat-sensitive nutrients and maintains structural integrity, making it ideal for pharmaceuticals and delicate food items. Spray-drying, on the other hand, offers faster processing and cost-efficiency, suitable for heat-stable materials and large-scale production. Understanding the trade-offs between retention of bioactive compounds and processing speed ensures optimal product quality and shelf life.

freeze-drying vs spray-drying Infographic

libmatt.com

libmatt.com