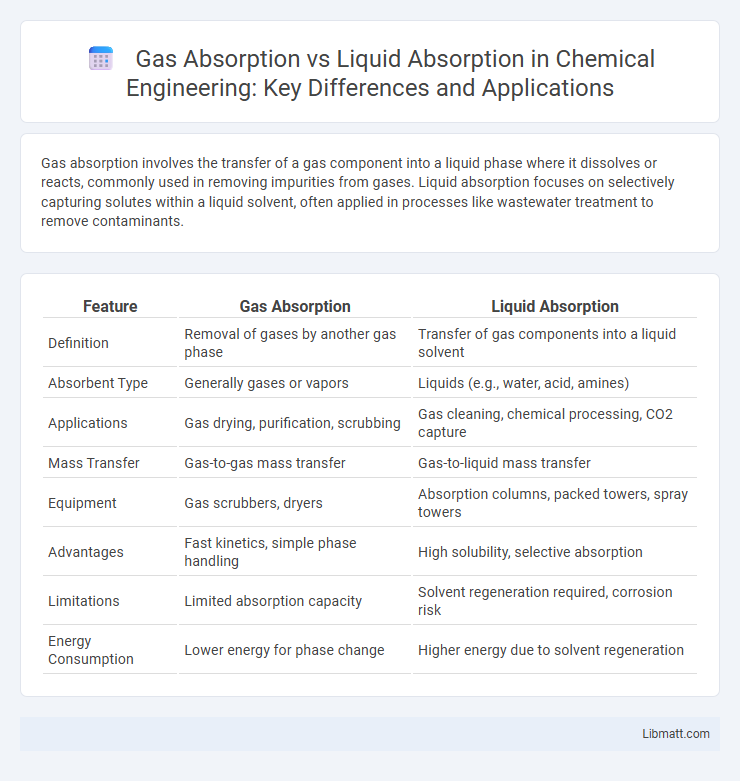

Gas absorption involves the transfer of a gas component into a liquid phase where it dissolves or reacts, commonly used in removing impurities from gases. Liquid absorption focuses on selectively capturing solutes within a liquid solvent, often applied in processes like wastewater treatment to remove contaminants.

Table of Comparison

| Feature | Gas Absorption | Liquid Absorption |

|---|---|---|

| Definition | Removal of gases by another gas phase | Transfer of gas components into a liquid solvent |

| Absorbent Type | Generally gases or vapors | Liquids (e.g., water, acid, amines) |

| Applications | Gas drying, purification, scrubbing | Gas cleaning, chemical processing, CO2 capture |

| Mass Transfer | Gas-to-gas mass transfer | Gas-to-liquid mass transfer |

| Equipment | Gas scrubbers, dryers | Absorption columns, packed towers, spray towers |

| Advantages | Fast kinetics, simple phase handling | High solubility, selective absorption |

| Limitations | Limited absorption capacity | Solvent regeneration required, corrosion risk |

| Energy Consumption | Lower energy for phase change | Higher energy due to solvent regeneration |

Introduction to Gas Absorption and Liquid Absorption

Gas absorption involves the transfer of a gaseous component into a liquid phase where it dissolves, commonly used in processes like scrubbing to remove pollutants from exhaust streams. Liquid absorption refers to the uptake of substances by a liquid, encompassing phenomena such as solvent extraction and the dissolution of solutes in solvents. Both gas and liquid absorption are critical in chemical engineering for separating mixtures, enhancing mass transfer efficiency and ensuring process optimization.

Fundamental Principles of Absorption Processes

Gas absorption involves the transfer of specific gas components into a liquid phase based on differences in partial pressure, relying on mass transfer principles and solubility. Liquid absorption, often referred to as liquid-liquid extraction, uses differences in solubility and chemical affinity between two immiscible liquids to selectively separate components. Both processes depend on equilibrium stages, mass transfer coefficients, and diffusion rates to optimize separation efficiency in industrial applications.

Key Differences Between Gas and Liquid Absorption

Gas absorption involves the transfer of specific gas components into a liquid solvent, whereas liquid absorption refers to the uptake of substances within one or more liquid phases. Gas absorption typically focuses on separating gaseous contaminants like CO2 or SO2 using solvents such as amines, while liquid absorption often deals with dissolving solutes within liquid mixtures for processes like extraction or purification. Your choice between gas and liquid absorption depends on the phase interaction, solvent properties, and target component characteristics.

Mechanisms of Gas Absorption

Gas absorption involves the transfer of gaseous molecules into a liquid phase through physical dissolution or chemical reaction mechanisms, where molecular diffusion drives the gas from the bulk phase into the liquid boundary layer. Physical absorption depends on the solubility of the gas in the liquid, influenced by factors like temperature, pressure, and Henry's law constants. Chemical absorption occurs when the gas reacts with components in the liquid to form new compounds, enhancing mass transfer rates and selectivity in processes such as CO2 capture using amine solutions.

Mechanisms of Liquid Absorption

Liquid absorption involves the transfer of gas molecules into a liquid phase where they dissolve and chemically or physically react. The mechanism includes molecular diffusion across the gas-liquid interface followed by solubility-dependent dissolution, often enhanced by chemical reactions within the liquid to increase absorption capacity. Your understanding of liquid absorption can improve process efficiency by optimizing factors such as temperature, pressure, and solvent selection to maximize gas uptake.

Factors Affecting Gas and Liquid Absorption Efficiency

Gas absorption efficiency depends on factors such as gas solubility, temperature, pressure, and contact time with the liquid absorbent. Liquid absorption efficiency is influenced by liquid composition, flow rate, viscosity, and the surface area available for mass transfer. Both processes benefit from optimized temperature and pressure conditions to enhance mass transfer rates and improve overall absorption performance.

Industrial Applications of Gas Absorption

Gas absorption plays a crucial role in industrial applications such as air pollution control, where it removes harmful gases like sulfur dioxide and ammonia from flue gases. Liquid absorption is widely employed in chemical manufacturing processes for extracting valuable components, such as in natural gas treatment to remove carbon dioxide and hydrogen sulfide. Efficient gas absorption systems improve environmental compliance and enhance process safety in industries like petrochemical refineries and power plants.

Industrial Applications of Liquid Absorption

Liquid absorption plays a crucial role in industrial applications such as gas purification, solvent recovery, and chemical processing. It effectively removes contaminants like sulfur compounds and carbon dioxide from gas streams, improving air quality and process efficiency. Your operations benefit from liquid absorption systems by achieving higher purification levels and enabling the recycling of valuable solvents.

Advantages and Disadvantages: Gas vs Liquid Absorption

Gas absorption offers rapid mass transfer rates and is ideal for removing volatile compounds, but it often requires complex equipment and higher operational costs. Liquid absorption provides better handling of soluble pollutants with easier regeneration of absorbents, though it may suffer from lower efficiency and slower processing times. Choosing between gas and liquid absorption depends on factors like pollutant properties, process conditions, and economic considerations.

Future Trends and Innovations in Absorption Technologies

Future trends in gas absorption emphasize advanced materials such as metal-organic frameworks (MOFs) and ionic liquids that enhance selectivity and capacity for carbon capture applications. Innovations in liquid absorption focus on energy-efficient solvents, including amine blends and phase-change solvents, to reduce regeneration costs and improve environmental sustainability. Emerging technologies integrate smart process control and hybrid absorption systems to optimize performance and minimize operational expenses in industrial gas treatment.

gas absorption vs liquid absorption Infographic

libmatt.com

libmatt.com