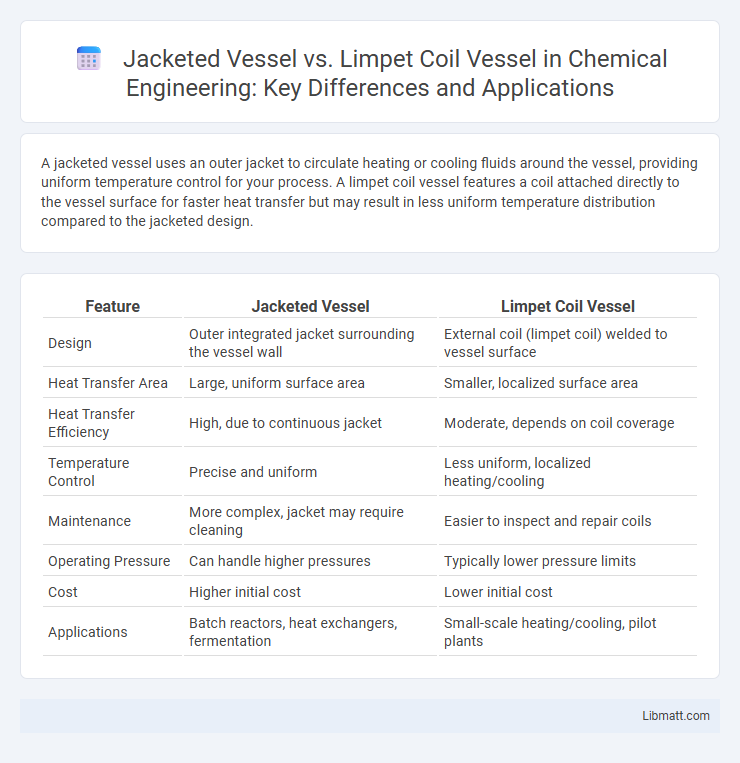

A jacketed vessel uses an outer jacket to circulate heating or cooling fluids around the vessel, providing uniform temperature control for your process. A limpet coil vessel features a coil attached directly to the vessel surface for faster heat transfer but may result in less uniform temperature distribution compared to the jacketed design.

Table of Comparison

| Feature | Jacketed Vessel | Limpet Coil Vessel |

|---|---|---|

| Design | Outer integrated jacket surrounding the vessel wall | External coil (limpet coil) welded to vessel surface |

| Heat Transfer Area | Large, uniform surface area | Smaller, localized surface area |

| Heat Transfer Efficiency | High, due to continuous jacket | Moderate, depends on coil coverage |

| Temperature Control | Precise and uniform | Less uniform, localized heating/cooling |

| Maintenance | More complex, jacket may require cleaning | Easier to inspect and repair coils |

| Operating Pressure | Can handle higher pressures | Typically lower pressure limits |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Batch reactors, heat exchangers, fermentation | Small-scale heating/cooling, pilot plants |

Introduction to Jacketed and Limpet Coil Vessels

Jacketed vessels feature an outer shell that creates a space for heating or cooling fluids to regulate the temperature of the vessel's contents efficiently. Limpet coil vessels incorporate external coils welded directly onto the vessel's wall, enabling precise thermal control by circulating heating or cooling media within the coil. Both vessel types are essential in industries requiring stringent temperature management, such as chemical processing and pharmaceuticals.

Design Features of Jacketed Vessels

Jacketed vessels feature a surrounding outer layer that allows temperature control through the circulation of heating or cooling fluids, providing uniform heat transfer and efficient process temperature regulation. Their design includes various jacket types such as conventional jacket, half-pipe coil jacket, or dimple jacket, each optimized for specific heat exchange requirements and pressure capabilities. You benefit from precise temperature maintenance and ease of cleaning with jacketed vessels due to their versatile construction and accessible internal components.

Design Features of Limpet Coil Vessels

Limpet coil vessels feature an external coil attached directly to the vessel wall, providing efficient heat transfer through fluid circulation within the coil. This design allows for precise temperature control and easier maintenance compared to jacketed vessels, which use a hollow outer shell for heating or cooling. Your choice of a limpet coil vessel can optimize thermal performance in processes requiring rapid or localized temperature adjustment.

Heat Transfer Efficiency Comparison

Jacketed vessels typically provide lower heat transfer efficiency due to the limited surface area contact between the heating medium and the vessel wall, resulting in slower temperature changes. Limpet coil vessels enhance heat transfer efficiency significantly by offering a larger heat exchange surface through coiled tubing attached directly to the vessel, enabling faster and more uniform heating or cooling. Your process benefits from choosing limpet coil vessels when precise temperature control and rapid heat transfer are critical for optimal performance.

Advantages of Jacketed Vessels

Jacketed vessels offer superior heat transfer efficiency due to the direct contact between the heating or cooling medium and the vessel jacket, enabling precise temperature control for sensitive processes. These vessels provide enhanced versatility by accommodating a wide range of fluids and operating conditions, including high pressures and temperatures. Maintenance and cleaning are simplified in jacketed vessels, minimizing downtime and ensuring consistent product quality in industrial applications.

Advantages of Limpet Coil Vessels

Limpet coil vessels offer superior heat transfer efficiency due to their direct contact heating or cooling design, enabling precise temperature control for chemical and pharmaceutical processes. Their compact coil arrangement minimizes fouling and allows easy maintenance, reducing downtime and operational costs. Enhanced thermal uniformity and rapid temperature adjustments make limpet coil vessels ideal for sensitive reactions requiring stringent thermal management.

Applications and Industry Usage

Jacketed vessels are widely used in the chemical, pharmaceutical, and food industries for precise temperature control during reactions, fermentations, and storage processes. Limpet coil vessels find applications mainly in chemical processing and petrochemical industries, where efficient heat transfer is required for heating or cooling fluids in continuous operations. Industrial sectors prioritize jacketed vessels for versatile temperature regulation, while limpet coil vessels are preferred for their efficient thermal performance in high-temperature, corrosive environments.

Maintenance and Cleaning Considerations

Jacketed vessels offer straightforward maintenance and cleaning due to their easily accessible outer jacket, which minimizes contamination risks and simplifies external inspection. Limpet coil vessels, with their internal coil design, often require more specialized cleaning methods and careful monitoring to prevent fouling or corrosion inside the coils. Your choice will impact downtime frequency and cleaning procedures, making jacketed vessels preferable for processes demanding quick and routine maintenance.

Cost Analysis: Jacketed vs Limpet Coil

Jacketed vessels generally incur higher initial costs due to complex fabrication and thicker materials required for the jacket, while limpet coil vessels often offer a more cost-effective solution with simpler design and easier installation. Operational costs for jacketed vessels may be reduced through better heat transfer efficiency, whereas limpet coil vessels may lead to higher energy consumption due to uneven heating. Your choice between the two should weigh upfront investments against long-term energy savings and maintenance expenses.

Choosing the Right Vessel for Your Process

Selecting the right vessel impacts heat transfer efficiency and process control, where jacketed vessels provide uniform external heating or cooling through a jacket filled with heat transfer fluid. Limpet coil vessels utilize internal coils welded to the vessel wall for direct thermal exchange, offering faster response and precise temperature management in smaller volumes. Evaluate your process requirements, fluid properties, and temperature targets to determine whether the uniform surface heating of a jacketed vessel or the rapid, targeted control of a limpet coil vessel best suits your operational needs.

jacketed vessel vs limpet coil vessel Infographic

libmatt.com

libmatt.com