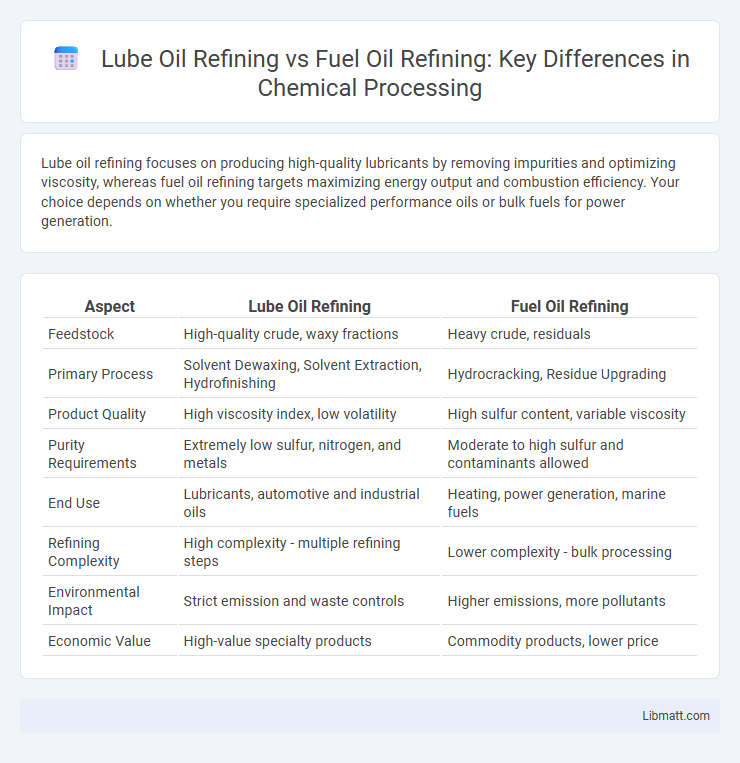

Lube oil refining focuses on producing high-quality lubricants by removing impurities and optimizing viscosity, whereas fuel oil refining targets maximizing energy output and combustion efficiency. Your choice depends on whether you require specialized performance oils or bulk fuels for power generation.

Table of Comparison

| Aspect | Lube Oil Refining | Fuel Oil Refining |

|---|---|---|

| Feedstock | High-quality crude, waxy fractions | Heavy crude, residuals |

| Primary Process | Solvent Dewaxing, Solvent Extraction, Hydrofinishing | Hydrocracking, Residue Upgrading |

| Product Quality | High viscosity index, low volatility | High sulfur content, variable viscosity |

| Purity Requirements | Extremely low sulfur, nitrogen, and metals | Moderate to high sulfur and contaminants allowed |

| End Use | Lubricants, automotive and industrial oils | Heating, power generation, marine fuels |

| Refining Complexity | High complexity - multiple refining steps | Lower complexity - bulk processing |

| Environmental Impact | Strict emission and waste controls | Higher emissions, more pollutants |

| Economic Value | High-value specialty products | Commodity products, lower price |

Introduction to Oil Refining: Lube Oil vs Fuel Oil

Lube oil refining involves a complex process focused on producing high-viscosity, thermally stable base oils essential for engine lubrication, using techniques like solvent extraction and hydroprocessing to enhance purity and performance. Fuel oil refining emphasizes maximizing yield of combustible hydrocarbons with varying viscosity grades, utilizing catalytic cracking and blending to meet energy output and emission standards. Both processes start with crude oil distillation but diverge into specialized treatments to meet distinct quality and application requirements.

Key Differences in Feedstocks

Lube oil refining primarily uses heavy distillates and vacuum gas oils as feedstocks, which contain higher molecular weight hydrocarbons suitable for producing high-viscosity lubricants. Fuel oil refining typically processes heavier residues and cracked stocks with a broader range of hydrocarbons to meet fuel performance standards. Your choice between these refining processes depends on the desired end product and feedstock availability.

Refining Process Overview for Lube Oils

Lube oil refining involves specialized vacuum distillation and solvent extraction methods to remove impurities and enhance viscosity, unlike fuel oil refining, which prioritizes maximizing energy content through catalytic cracking and hydro-treating. The refining process for lube oils includes dewaxing and clay treatment to ensure improved thermal stability and oxidation resistance, critical for performance in engines and machinery. Your choice of lube oil refinery must focus on precise temperature control and purification steps tailored for high-quality lubricant production.

Refining Process Overview for Fuel Oils

Fuel oil refining primarily involves distillation followed by processes such as cracking, coking, and desulfurization to convert heavy residual oils into usable fuel products. The refining process separates hydrocarbons based on boiling points, optimizing fuel oil quality for diverse applications including power generation and marine fuels. Advanced techniques like hydrotreating enhance sulfur removal and improve combustion efficiency, aligning with stringent environmental regulations.

Major Technologies Used in Lube Oil Refining

Lube oil refining primarily employs solvent extraction, hydrofinishing, and dewaxing technologies to enhance viscosity, purity, and stability, distinguishing it from fuel oil refining which focuses more on catalytic cracking and coking. Solvent extraction removes aromatic compounds to improve oxidation stability, while hydrofinishing saturates sulfur and nitrogen compounds, producing high-quality base oils. Dewaxing processes use catalytic or solvent methods to ensure low pour points, critical for lube oil performance in cold conditions.

Major Technologies Used in Fuel Oil Refining

Fuel oil refining primarily employs thermal cracking, catalytic cracking, and visbreaking technologies to break down heavy hydrocarbons into more valuable, lighter fractions. Fluid catalytic cracking (FCC) is a dominant process, using a catalyst to enhance efficiency and yield high-quality fuel oils and diesel. Your refinery can optimize fuel oil production by integrating these advanced technologies tailored to feedstock characteristics and market demand.

Product Quality Requirements: Lube Oil vs Fuel Oil

Lube oil refining demands higher product quality requirements, including stricter viscosity control, thermal stability, and low impurities to ensure optimal engine protection and performance. Fuel oil refining prioritizes combustion efficiency and sulfur content limitations, with less stringent viscosity and purity standards compared to lube oils. The refining processes for lube oils involve advanced treatments like solvent extraction and dewaxing, which are typically unnecessary for fuel oil production.

Environmental Considerations in Both Refining Processes

Lube oil refining and fuel oil refining both present significant environmental challenges, particularly in emissions control and waste management. Lube oil refining involves advanced hydrotreating processes to minimize sulfur and aromatic compounds, reducing air pollutants and ensuring compliance with stricter environmental regulations. Your choice in refining method can impact ecological footprints, with fuel oil refining typically generating higher sulfur oxide (SOx) emissions and requiring more extensive treatment to meet environmental standards.

Economic Implications of Lube vs Fuel Oil Refining

Lube oil refining generates higher profit margins due to the production of specialty lubricants that command premium prices, driven by stringent quality standards and complex processing techniques. Fuel oil refining, while operating on larger volumes, often yields lower economic returns because of fluctuating crude oil prices and competitive market conditions for bulk energy commodities. Investment in advanced catalytic processes and additives in lube oil refining enhances value creation compared to the relatively simpler distillation and blending methods used in fuel oil refining.

Future Trends and Innovations in Oil Refining

Future trends in lube oil refining emphasize the development of advanced hydroprocessing technologies to produce higher-quality base oils with improved viscosity and oxidation stability. Innovations in fuel oil refining focus on reducing sulfur content and enhancing fuel efficiency by adopting hydrocracking and catalytic desulfurization processes in response to stringent environmental regulations. Both sectors are increasingly integrating digital refinery management systems and AI-driven process optimization to boost operational efficiency and reduce emissions.

Lube oil refining vs fuel oil refining Infographic

libmatt.com

libmatt.com