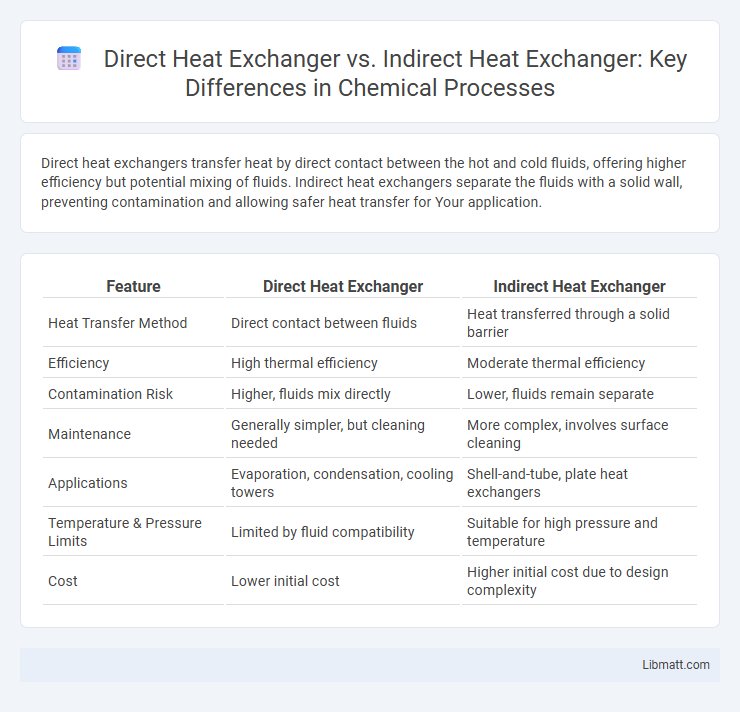

Direct heat exchangers transfer heat by direct contact between the hot and cold fluids, offering higher efficiency but potential mixing of fluids. Indirect heat exchangers separate the fluids with a solid wall, preventing contamination and allowing safer heat transfer for Your application.

Table of Comparison

| Feature | Direct Heat Exchanger | Indirect Heat Exchanger |

|---|---|---|

| Heat Transfer Method | Direct contact between fluids | Heat transferred through a solid barrier |

| Efficiency | High thermal efficiency | Moderate thermal efficiency |

| Contamination Risk | Higher, fluids mix directly | Lower, fluids remain separate |

| Maintenance | Generally simpler, but cleaning needed | More complex, involves surface cleaning |

| Applications | Evaporation, condensation, cooling towers | Shell-and-tube, plate heat exchangers |

| Temperature & Pressure Limits | Limited by fluid compatibility | Suitable for high pressure and temperature |

| Cost | Lower initial cost | Higher initial cost due to design complexity |

Introduction to Heat Exchangers

Direct heat exchangers transfer thermal energy by allowing two fluids to come into direct contact, facilitating efficient heat exchange without barriers. Indirect heat exchangers use a solid wall or partition to separate fluids, preventing mixing while enabling heat transfer through conduction. These fundamental types serve diverse industrial applications by optimizing thermal efficiency and operational requirements.

Understanding Direct Heat Exchangers

Direct heat exchangers transfer heat through direct contact between the hot and cold fluids, enabling efficient energy exchange without barriers. They are commonly used in applications where mixing of fluids is acceptable or desired, such as evaporative cooling or gas scrubbing processes. Your choice of a direct heat exchanger depends on factors like fluid compatibility, temperature control, and maintenance requirements to optimize performance.

Understanding Indirect Heat Exchangers

Indirect heat exchangers transfer heat between two fluids without mixing them, using a solid barrier like a metal wall to separate the heat exchange surfaces. This design prevents contamination and allows precise control over temperature, making them ideal for processes requiring hygiene or fluid purity. Understanding your system's needs will help determine if an indirect heat exchanger suits applications where fluid separation is critical.

Key Differences Between Direct and Indirect Heat Exchangers

Direct heat exchangers transfer heat by allowing fluids to come into direct contact, maximizing heat transfer efficiency but risking contamination. Indirect heat exchangers separate fluids with a solid barrier, preventing mixing while maintaining thermal exchange through conduction. Your choice depends on factors like contamination risk, maintenance requirements, and the specific thermal performance needed for your application.

Efficiency Comparison: Direct vs Indirect Heat Exchangers

Direct heat exchangers generally offer higher thermal efficiency due to the direct contact between hot and cold fluids, enabling rapid heat transfer with minimal energy loss. Indirect heat exchangers, while slightly less efficient because of the intermediary barrier, provide better control over contamination and fluid separation, making them suitable for sensitive applications. Efficiency in direct heat exchangers can exceed 90%, whereas indirect types typically achieve 70-85% efficiency depending on design and materials used.

Applications of Direct Heat Exchangers

Direct heat exchangers are widely used in applications where fluids mix directly, such as evaporative cooling, steam heating, and certain cooling tower operations. These exchangers are ideal for processes requiring rapid heat transfer with low temperature gradients, commonly found in chemical processing, food industry pasteurization, and HVAC systems. Their simplicity and efficiency make them suitable for large-scale industrial applications and energy recovery systems.

Applications of Indirect Heat Exchangers

Indirect heat exchangers are widely used in applications requiring isolation between fluids to prevent contamination, such as in chemical processing, HVAC systems, and power plants. These exchangers efficiently transfer heat through a solid barrier, making them ideal for handling corrosive, flammable, or toxic fluids where safety and product purity are critical. Your choice of an indirect heat exchanger ensures reliable thermal management without direct fluid contact, enhancing operational safety and process control.

Advantages and Disadvantages of Direct Heat Exchangers

Direct heat exchangers offer high thermal efficiency by allowing direct contact between fluids, which facilitates rapid heat transfer and reduces energy loss. However, this design can lead to contamination issues since fluids mix, making it unsuitable for applications requiring strict separation or hygiene standards. Your choice depends on whether maximizing heat transfer efficiency outweighs potential cleanliness and maintenance concerns.

Advantages and Disadvantages of Indirect Heat Exchangers

Indirect heat exchangers offer the advantage of preventing the mixing of fluids, ensuring contamination-free heat transfer essential for sensitive industrial processes. Their design allows handling of fluids at different pressures and temperatures, increasing safety and efficiency in applications such as chemical manufacturing and power plants. You should consider the higher initial cost and maintenance complexity as potential disadvantages when selecting an indirect heat exchanger.

Choosing the Right Heat Exchanger for Your Application

Direct heat exchangers transfer heat through direct contact between the hot and cold fluids, offering higher efficiency but posing contamination risks, making them ideal for applications like evaporators or cooling towers. Indirect heat exchangers use a separating wall to prevent fluid mixing, ensuring purity and safety, which suits chemical processing, HVAC systems, and food industries. Selecting the right heat exchanger depends on factors such as fluid compatibility, contamination sensitivity, maintenance requirements, and thermal efficiency needed for your specific industrial or commercial application.

Direct heat exchanger vs indirect heat exchanger Infographic

libmatt.com

libmatt.com