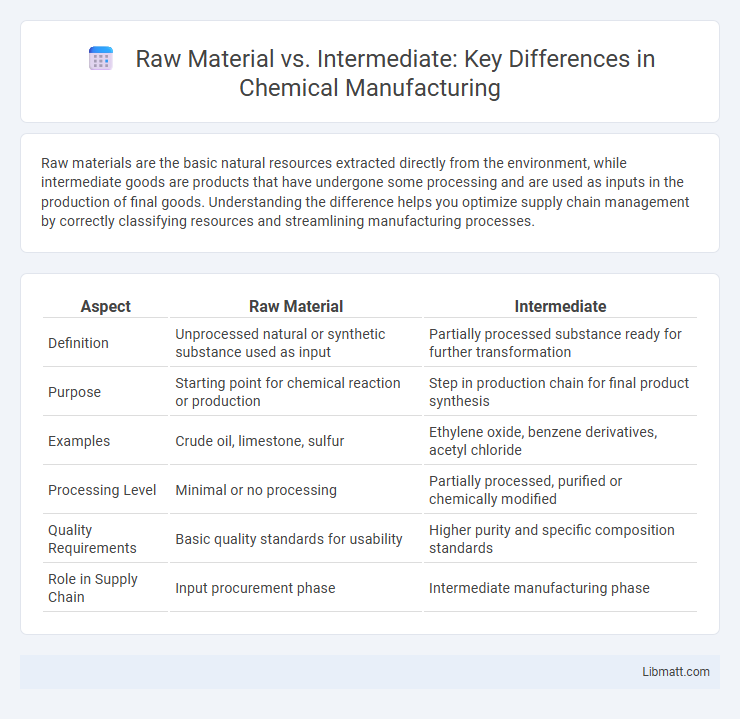

Raw materials are the basic natural resources extracted directly from the environment, while intermediate goods are products that have undergone some processing and are used as inputs in the production of final goods. Understanding the difference helps you optimize supply chain management by correctly classifying resources and streamlining manufacturing processes.

Table of Comparison

| Aspect | Raw Material | Intermediate |

|---|---|---|

| Definition | Unprocessed natural or synthetic substance used as input | Partially processed substance ready for further transformation |

| Purpose | Starting point for chemical reaction or production | Step in production chain for final product synthesis |

| Examples | Crude oil, limestone, sulfur | Ethylene oxide, benzene derivatives, acetyl chloride |

| Processing Level | Minimal or no processing | Partially processed, purified or chemically modified |

| Quality Requirements | Basic quality standards for usability | Higher purity and specific composition standards |

| Role in Supply Chain | Input procurement phase | Intermediate manufacturing phase |

Understanding Raw Materials: Definition and Importance

Raw materials are unprocessed natural substances extracted directly from the earth, serving as the essential foundation for manufacturing and production processes. Their quality and availability significantly impact the efficiency and cost-effectiveness of your supply chain. Understanding raw materials is crucial for optimizing production workflows and ensuring the consistent quality of intermediate goods.

What Are Intermediates? Key Characteristics

Intermediates are substances produced during the middle stages of a manufacturing process, serving as essential inputs for the creation of final products. They differ from raw materials, which are unprocessed natural resources or basic inputs, by undergoing partial processing or refinement before further use. Understanding the key characteristics of intermediates helps optimize your production workflow and improve overall supply chain efficiency.

Differences Between Raw Materials and Intermediates

Raw materials are the basic, unprocessed substances extracted directly from nature, serving as the foundational inputs in manufacturing processes. Intermediates are partially processed materials transformed from raw materials, used as inputs in further production stages to create finished goods. Understanding the difference helps optimize your supply chain by efficiently managing the flow from raw resource acquisition to intermediate production before final assembly.

Role of Raw Materials in Manufacturing Processes

Raw materials serve as the essential foundational inputs in manufacturing processes, providing the basic substances and compounds necessary for production. They undergo initial processing to become intermediate goods, which are then further refined or assembled into final products. Efficient utilization of raw materials directly impacts product quality, production cost, and overall supply chain effectiveness.

How Intermediates Bridge Production Stages

Intermediates function as crucial links between raw materials and final products by undergoing initial processing that transforms basic inputs into partially finished goods. These semi-processed materials streamline production workflows, enabling manufacturers to efficiently scale operations and maintain consistent quality across multiple stages. By serving as standardized components, intermediates facilitate supply chain integration and reduce the complexity of converting raw resources into finished products.

Procurement Strategies: Sourcing Raw Materials vs Intermediates

Procurement strategies for raw materials prioritize bulk purchasing and long-term supplier contracts to ensure consistent quality and cost efficiency, often involving direct relationships with primary producers. Sourcing intermediates demands flexibility and responsiveness due to their position within the manufacturing process, emphasizing just-in-time procurement and supplier diversification to mitigate supply chain disruptions. Effective procurement balances cost, lead time, and quality control between raw materials and intermediates to optimize overall production efficiency.

Quality Control in Raw Materials and Intermediates

Quality control in raw materials ensures the purity, composition, and consistency critical for reliable production, preventing defects early in the supply chain. Intermediate quality control focuses on verifying chemical and physical properties meet specifications before further processing, reducing waste and ensuring product efficacy. Implementing standardized testing protocols and real-time monitoring systems in both stages optimizes overall manufacturing quality and compliance with industry standards.

Cost Implications: Raw Materials vs Intermediate Products

Raw materials typically incur lower upfront costs but require additional processing, increasing overall production expenses. Intermediate products often have higher purchase prices but reduce in-house manufacturing costs by simplifying production stages. Understanding your supply chain's cost structure helps optimize budget allocation between raw materials and intermediates.

Environmental Impact: Raw Material Extraction vs Intermediate Processing

Raw material extraction often leads to significant environmental impacts such as habitat destruction, soil erosion, and high carbon emissions due to mining or harvesting processes. Intermediate processing, while consuming energy and generating waste, typically has a lower environmental footprint compared to raw extraction since it adds value by converting raw inputs into usable products with improved efficiency. Optimizing Your supply chain by prioritizing sustainable intermediate processing can reduce overall environmental impact and support greener manufacturing practices.

Future Trends in Raw Material and Intermediate Management

Advancements in digital technologies and AI-driven analytics are transforming raw material and intermediate management by enabling more precise demand forecasting and inventory optimization. Sustainable sourcing practices and circular economy models are increasingly prioritized to reduce environmental impact and regulatory risks in supply chains. Integration of blockchain technology enhances traceability and transparency, ensuring authenticity and compliance for raw materials and intermediates.

raw material vs intermediate Infographic

libmatt.com

libmatt.com