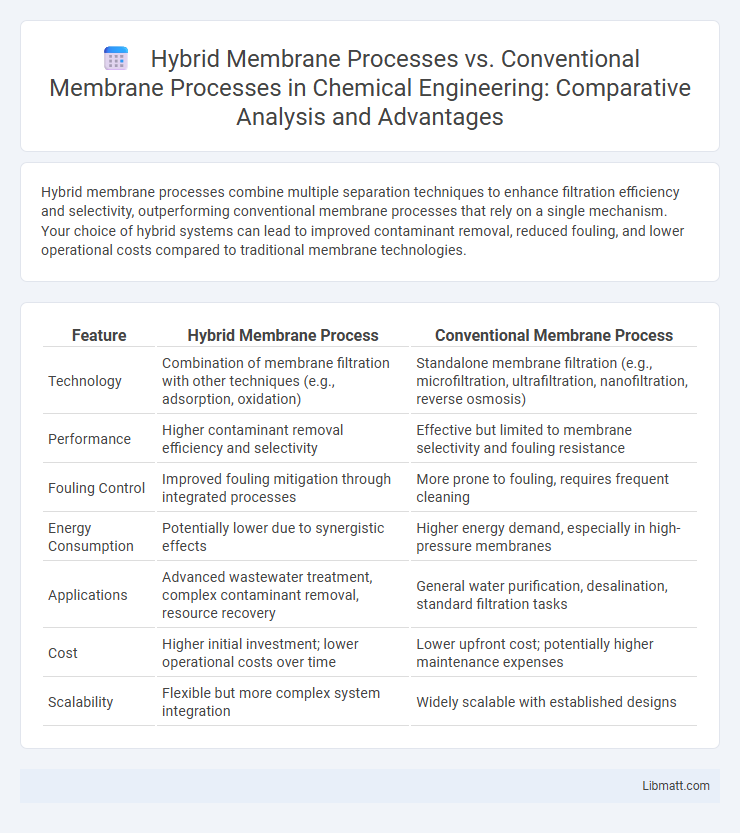

Hybrid membrane processes combine multiple separation techniques to enhance filtration efficiency and selectivity, outperforming conventional membrane processes that rely on a single mechanism. Your choice of hybrid systems can lead to improved contaminant removal, reduced fouling, and lower operational costs compared to traditional membrane technologies.

Table of Comparison

| Feature | Hybrid Membrane Process | Conventional Membrane Process |

|---|---|---|

| Technology | Combination of membrane filtration with other techniques (e.g., adsorption, oxidation) | Standalone membrane filtration (e.g., microfiltration, ultrafiltration, nanofiltration, reverse osmosis) |

| Performance | Higher contaminant removal efficiency and selectivity | Effective but limited to membrane selectivity and fouling resistance |

| Fouling Control | Improved fouling mitigation through integrated processes | More prone to fouling, requires frequent cleaning |

| Energy Consumption | Potentially lower due to synergistic effects | Higher energy demand, especially in high-pressure membranes |

| Applications | Advanced wastewater treatment, complex contaminant removal, resource recovery | General water purification, desalination, standard filtration tasks |

| Cost | Higher initial investment; lower operational costs over time | Lower upfront cost; potentially higher maintenance expenses |

| Scalability | Flexible but more complex system integration | Widely scalable with established designs |

Introduction to Membrane Processes

Membrane processes use selective barriers to separate substances based on size or chemical properties, enabling efficient purification and separation in water treatment and industrial applications. Hybrid membrane processes combine multiple membrane technologies or integrate membranes with other treatment methods to enhance performance, increase flux, and reduce fouling compared to conventional single-stage membrane systems. These hybrid systems offer improved contaminant removal, energy efficiency, and operational flexibility, making them suitable for complex wastewater or brackish water treatment challenges.

Overview of Conventional Membrane Processes

Conventional membrane processes such as microfiltration, ultrafiltration, nanofiltration, and reverse osmosis primarily rely on size exclusion and pressure-driven separation to remove contaminants from water. These methods effectively target specific particle sizes and dissolved substances but can face challenges like fouling and limited removal of certain dissolved organics or gases. Understanding these characteristics helps you evaluate the advantages hybrid membrane processes offer by integrating complementary technologies for enhanced treatment efficiency.

What is a Hybrid Membrane Process?

A Hybrid Membrane Process combines conventional membrane filtration with supplementary treatment technologies such as advanced oxidation, adsorption, or biological treatment to enhance contaminant removal efficiency and reduce membrane fouling. This integrated approach achieves higher water recovery rates and improved pollutant rejection compared to conventional membrane processes that rely solely on physical separation methods like microfiltration, ultrafiltration, nanofiltration, or reverse osmosis. The hybrid system optimizes operational costs and extends membrane lifespan by mitigating common issues such as membrane scaling and biofouling.

Key Differences Between Hybrid and Conventional Membrane Systems

Hybrid membrane processes combine traditional membrane filtration with complementary technologies such as adsorption or advanced oxidation, enhancing contaminant removal efficiency and extending membrane lifespan. Conventional membrane systems rely solely on pressure-driven filtration methods like microfiltration, ultrafiltration, nanofiltration, or reverse osmosis, which may face limitations with fouling and selectivity. Your choice between these systems impacts operational costs, treatment performance, and environmental footprint, making hybrid solutions attractive for complex water treatment challenges.

Performance Comparison: Hybrid vs Conventional Membranes

Hybrid membrane processes combine multiple separation mechanisms, enhancing contaminant removal efficiency and achieving higher flux rates compared to conventional membranes, which rely on a single separation technique. The integration of techniques such as adsorption or advanced oxidation within hybrid membranes improves selectivity and reduces fouling, resulting in longer membrane lifespan and lower operational costs. Conventional membrane processes typically exhibit lower rejection rates for complex pollutants and are more prone to fouling, leading to increased maintenance frequency and reduced overall system performance.

Efficiency and Energy Consumption Analysis

Hybrid membrane processes exhibit significantly enhanced separation efficiency compared to conventional membrane processes by integrating multiple separation mechanisms, resulting in higher permeate flux and improved rejection rates. Energy consumption in hybrid systems is notably reduced due to optimized process configurations, such as combining membrane filtration with pre-treatment or hybrid driving forces that lower hydraulic pressure requirements. Studies demonstrate energy savings of up to 30-50% in hybrid membrane processes, making them a more sustainable choice for water and wastewater treatment applications.

Cost Considerations and Economic Feasibility

Hybrid membrane processes often offer lower operational costs compared to conventional membrane processes by combining multiple filtration methods to enhance efficiency and reduce energy consumption. Although initial capital expenses for hybrid systems may be higher due to complex equipment integration, the improved membrane lifespan and reduced chemical usage result in better long-term economic feasibility. Your choice between these technologies should factor in the total cost of ownership, including maintenance, energy, and replacement costs, to optimize cost-effectiveness in water treatment applications.

Applications in Water and Wastewater Treatment

Hybrid membrane processes combine membrane filtration with other treatment technologies like coagulation, adsorption, or advanced oxidation, enhancing removal efficiency of contaminants in water and wastewater treatment. These processes effectively target a broader range of pollutants, including micropollutants, pharmaceuticals, and emerging contaminants, which conventional membrane processes alone may not fully remove. Hybrid systems improve overall treatment performance, reduce membrane fouling, and extend membrane lifespan in applications such as drinking water purification, industrial wastewater treatment, and municipal sewage management.

Environmental Impact and Sustainability

Hybrid membrane processes combine multiple filtration techniques, significantly reducing energy consumption and chemical usage compared to conventional membrane processes, enhancing overall environmental sustainability. These systems typically lower greenhouse gas emissions and minimize wastewater production by improving separation efficiency and membrane lifespan. Your choice of hybrid membranes supports greener operations through reduced resource depletion and improved waste management in water treatment applications.

Future Trends in Membrane Technologies

Hybrid membrane processes combine multiple separation techniques to enhance filtration efficiency and energy savings, outperforming conventional membrane processes. Future trends emphasize integrating advanced materials like graphene oxide and nanocomposites to improve membrane selectivity and fouling resistance. You can expect smart membranes with real-time monitoring capabilities and adaptive performance to revolutionize water treatment and industrial separation.

Hybrid membrane process vs conventional membrane process Infographic

libmatt.com

libmatt.com