Clamshell packages feature a hinged design that allows for easy opening and secure closure, ideal for retail displays and reusable purposes. Split mold packages consist of two separate halves that encase the product, offering a more rigid and tamper-evident solution for protection during shipping and handling.

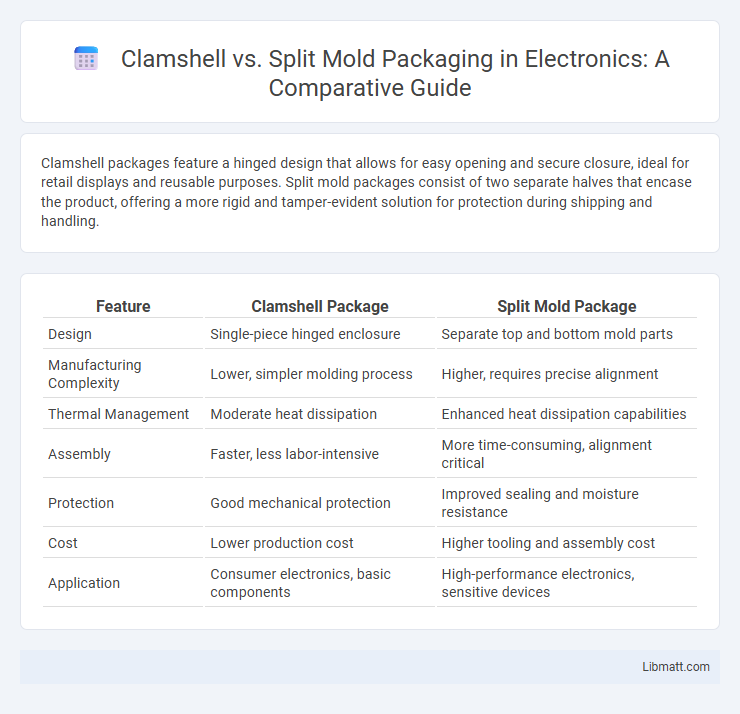

Table of Comparison

| Feature | Clamshell Package | Split Mold Package |

|---|---|---|

| Design | Single-piece hinged enclosure | Separate top and bottom mold parts |

| Manufacturing Complexity | Lower, simpler molding process | Higher, requires precise alignment |

| Thermal Management | Moderate heat dissipation | Enhanced heat dissipation capabilities |

| Assembly | Faster, less labor-intensive | More time-consuming, alignment critical |

| Protection | Good mechanical protection | Improved sealing and moisture resistance |

| Cost | Lower production cost | Higher tooling and assembly cost |

| Application | Consumer electronics, basic components | High-performance electronics, sensitive devices |

Introduction to Clamshell and Split Mold Packaging

Clamshell and split mold packaging are widely used in various industries for protecting and displaying products effectively. Clamshell packaging features a hinged design that securely encloses items, offering tamper resistance and clear product visibility. Split mold packaging consists of two separate molds that fit together, providing precise shaping and enhanced durability for safeguarding your goods during shipping and storage.

What is a Clamshell Package?

A Clamshell Package is a type of plastic enclosure designed for product display and protection, featuring two hinged halves that open and close like a clamshell. It offers high visibility and durability, making it ideal for retail packaging where product presentation is crucial. Your choice of this packaging ensures secure containment and ease of access while minimizing the risk of damage during handling and shipping.

What is a Split Mold Package?

A Split Mold Package is a type of semiconductor packaging that uses two separate mold halves to encapsulate the integrated circuit, allowing for precise control over the sealing process and improved mechanical protection. This packaging technique enhances thermal dissipation and electrical performance by minimizing stress on the chip and providing better uniformity compared to traditional clamshell designs. Split Mold Packages are commonly used in advanced electronic devices where reliability and compact size are critical.

Design Differences: Clamshell vs Split Mold

Clamshell packages feature a hinged design allowing the top and bottom halves to close and open easily, providing user-friendly access and enhanced product protection. Split mold packages are constructed using two separate molds joined together, resulting in a more rigid and precise enclosure ideal for secure sealing and tamper resistance. The clamshell design emphasizes convenience and visibility, while split mold packages prioritize durability and structural integrity.

Material Choices in Packaging

Clamshell and split mold packages differ significantly in material choices, with clamshells often utilizing rigid PET or PVC plastics that offer superior durability and visibility for product display. Split mold packages typically employ more flexible, softer materials like polyethylene or polypropylene, which facilitate easier molding and cost-effectiveness in production. Your choice between these packaging types should consider the balance between protection, aesthetic appeal, and environmental sustainability based on the material characteristics.

Ease of Use and Accessibility

Clamshell molds offer straightforward access and simple operation due to their hinged design, making product installation and removal faster and less labor-intensive. Split mold packages, with their multiple segmented components, provide greater flexibility for complex shapes but can require more careful alignment and assembly, potentially increasing operation time. Ease of use in clamshell molds reduces downtime, while split molds enhance versatility at the cost of slightly higher handling complexity.

Security and Tamper Resistance

Clamshell packages offer moderate security by enclosing items in a sealed plastic casing that deters casual tampering but can be pried open with tools. Split mold packages provide enhanced tamper resistance through a two-part molded design that interlocks tightly, making unauthorized access more difficult without visible damage. For high-security applications, split mold packaging is preferred due to its robust structural integrity and clear evidence of tampering.

Cost Comparison

Clamshell mold packages generally offer lower initial tooling costs compared to split mold packages due to their simpler design and reduced machining requirements. Split mold packages, while more expensive upfront, provide greater flexibility and precision for complex geometries which can reduce long-term manufacturing expenses. Your choice should consider both immediate budget constraints and the potential impact on production efficiency and part quality.

Sustainability and Environmental Impact

Clamshell and split mold packages differ significantly in sustainability, with clamshell designs often relying on single-material plastics that are easier to recycle and reduce environmental waste. Split mold packages typically involve multiple materials or composites, complicating recycling processes and increasing landfill contributions. Choosing clamshell packaging supports improved recyclability and lower carbon footprints in product distribution and disposal.

Choosing the Right Packaging for Your Product

Choosing the right packaging between clamshell and split mold packages depends on product protection, visibility, and ease of handling. Clamshell packaging offers a durable, tamper-resistant enclosure ideal for retail display and secure transport, while split mold packaging provides customizable compartments for delicate, multi-component products. Evaluating your product's shape, fragility, and retail environment helps determine the optimal packaging solution to enhance customer appeal and reduce damage.

Clamshell vs Split Mold Package Infographic

libmatt.com

libmatt.com