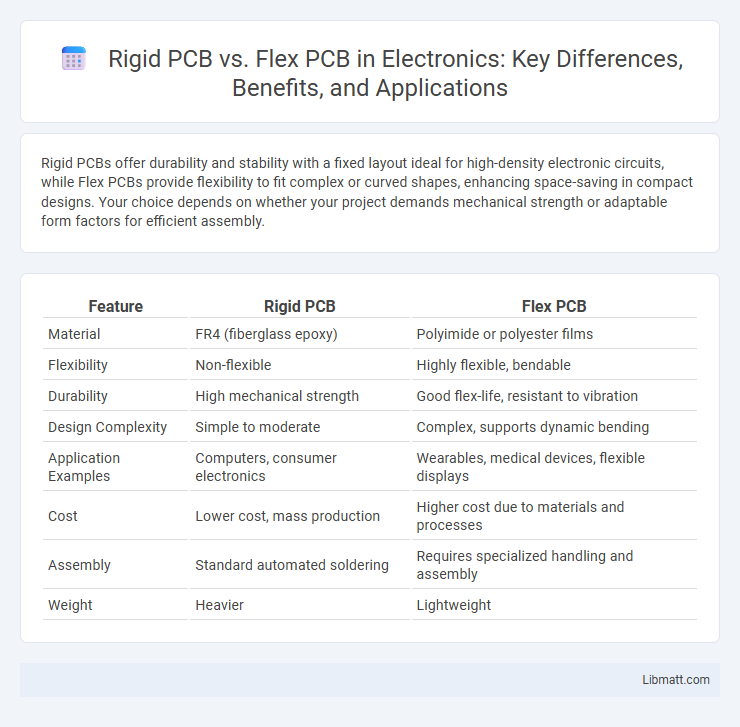

Rigid PCBs offer durability and stability with a fixed layout ideal for high-density electronic circuits, while Flex PCBs provide flexibility to fit complex or curved shapes, enhancing space-saving in compact designs. Your choice depends on whether your project demands mechanical strength or adaptable form factors for efficient assembly.

Table of Comparison

| Feature | Rigid PCB | Flex PCB |

|---|---|---|

| Material | FR4 (fiberglass epoxy) | Polyimide or polyester films |

| Flexibility | Non-flexible | Highly flexible, bendable |

| Durability | High mechanical strength | Good flex-life, resistant to vibration |

| Design Complexity | Simple to moderate | Complex, supports dynamic bending |

| Application Examples | Computers, consumer electronics | Wearables, medical devices, flexible displays |

| Cost | Lower cost, mass production | Higher cost due to materials and processes |

| Assembly | Standard automated soldering | Requires specialized handling and assembly |

| Weight | Heavier | Lightweight |

Introduction to Rigid PCB and Flex PCB

Rigid PCBs feature a solid, inflexible substrate that provides stable and durable circuit connections ideal for traditional electronics. Flex PCBs consist of flexible materials like polyimide, enabling your device to bend and conform to unique shapes while maintaining electrical performance. Choosing between rigid and flex PCB depends on your specific application needs, such as space constraints, durability, and design complexity.

Construction and Material Differences

Rigid PCBs are constructed with multiple layers of fiberglass epoxy laminate, which provides a solid, inflexible foundation ideal for stable electronic assemblies. Flex PCBs use flexible polyimide or polyester films as the base material, allowing circuits to bend and conform to dynamic or compact designs. Your choice between rigid and flex PCBs will depend on the mechanical requirements and environmental conditions of your electronic project.

Design Flexibility and Adaptability

Rigid PCBs offer limited design flexibility due to their fixed, inflexible substrate, making them ideal for straightforward, stable circuit layouts. Flex PCBs provide exceptional adaptability with bendable materials that accommodate complex geometries and dynamic movement, optimizing space in compact and irregularly shaped devices. The inherent design versatility of flex PCBs enables integration into wearable technology, aerospace, and medical devices where durability and spatial efficiency are critical.

Mechanical Durability and Reliability

Rigid PCBs offer superior mechanical durability due to their solid construction, making them ideal for applications subject to high stress and vibration. Flex PCBs provide enhanced reliability in dynamic environments by accommodating movement and bending without compromising electrical integrity. The choice between rigid and flex PCBs depends on the mechanical demands and flexibility requirements of the specific electronic device.

Space and Weight Considerations

Rigid PCBs provide stability and durability but are bulkier and heavier compared to Flex PCBs, which offer significant space and weight savings due to their thin, lightweight design. Flex PCBs are ideal for compact devices and applications where minimizing weight is crucial, such as in aerospace or wearable technology. Your choice between Rigid and Flex PCBs should consider the specific space constraints and weight requirements of your project to optimize performance and design efficiency.

Manufacturing Process Comparison

Rigid PCBs require a multi-step manufacturing process involving substrate lamination, drilling, etching, and solder mask application, typically using fiberglass or composite materials for firmness. Flex PCBs utilize flexible polyimide or polyester films, necessitating precise layering and bending steps, often incorporating additive techniques to reduce stress and maintain circuit integrity during flexing. The manufacturing complexity of flex PCBs usually demands specialized equipment and quality control measures to ensure durability and performance in dynamic applications.

Cost Analysis: Rigid PCB vs Flex PCB

Rigid PCBs generally incur lower manufacturing costs due to simpler materials and standardized production processes, making them ideal for high-volume applications. Flex PCBs, constructed from flexible substrates like polyimide, entail higher costs driven by complex fabrication, specialized materials, and intricate design requirements. Cost analysis should factor in not only initial production expenses but also long-term benefits such as space savings, reduced assembly labor, and improved durability associated with flex PCBs.

Typical Applications and Use Cases

Rigid PCBs are commonly used in consumer electronics, automotive controls, and industrial machinery due to their durability and structural stability. Flex PCBs excel in applications requiring dynamic movement or tight space constraints, such as wearable devices, medical implants, and aerospace systems. Your choice between rigid and flex PCB depends on the mechanical demands and spatial requirements of the specific application.

Performance in Extreme Environments

Rigid PCBs offer exceptional mechanical stability and thermal resistance, making them suitable for high-temperature and vibration-heavy environments such as aerospace and automotive applications. Flex PCBs excel in dynamic environments due to their ability to bend and absorb shocks without compromising electrical performance, ideal for wearable technology and medical devices. Both PCB types maintain signal integrity under extreme conditions, but Flex PCBs provide superior adaptability for compact and irregularly shaped designs.

Choosing the Right PCB for Your Project

Selecting the right PCB for your project depends on factors such as space constraints, mechanical flexibility, and reliability requirements. Rigid PCBs offer durability and stable performance for fixed applications, while flex PCBs provide lightweight, bendable solutions ideal for compact, dynamic environments. Evaluating design complexity, cost, and environmental conditions ensures optimal PCB choice for efficient functionality and long-term performance.

Rigid PCB vs Flex PCB Infographic

libmatt.com

libmatt.com