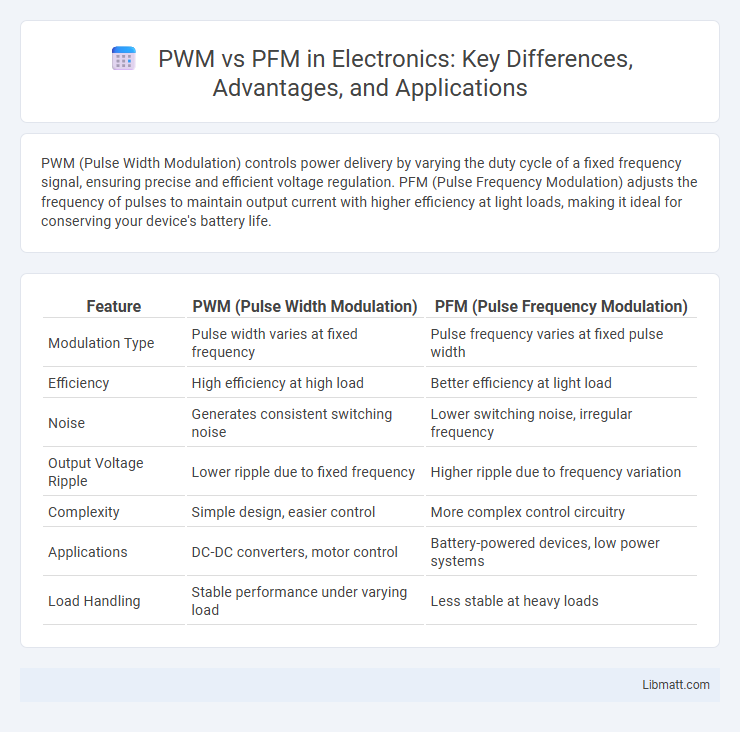

PWM (Pulse Width Modulation) controls power delivery by varying the duty cycle of a fixed frequency signal, ensuring precise and efficient voltage regulation. PFM (Pulse Frequency Modulation) adjusts the frequency of pulses to maintain output current with higher efficiency at light loads, making it ideal for conserving your device's battery life.

Table of Comparison

| Feature | PWM (Pulse Width Modulation) | PFM (Pulse Frequency Modulation) |

|---|---|---|

| Modulation Type | Pulse width varies at fixed frequency | Pulse frequency varies at fixed pulse width |

| Efficiency | High efficiency at high load | Better efficiency at light load |

| Noise | Generates consistent switching noise | Lower switching noise, irregular frequency |

| Output Voltage Ripple | Lower ripple due to fixed frequency | Higher ripple due to frequency variation |

| Complexity | Simple design, easier control | More complex control circuitry |

| Applications | DC-DC converters, motor control | Battery-powered devices, low power systems |

| Load Handling | Stable performance under varying load | Less stable at heavy loads |

Introduction to PWM and PFM

Pulse Width Modulation (PWM) controls power delivery by varying the duty cycle of a constant-frequency signal, enabling precise regulation of voltage and current in applications like motor drives and LED dimming. Pulse Frequency Modulation (PFM) adjusts the frequency of pulses while keeping the pulse width constant, optimizing efficiency at light loads and reducing electromagnetic interference in battery-powered devices. Both techniques are essential in power management for their unique approaches to balancing performance and energy consumption.

What is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a technique used to control the voltage delivered to electrical devices by varying the width of the pulses in a pulse train. PWM signals switch between on and off states at a fixed frequency, with the duty cycle representing the proportion of the 'on' time, directly influencing power output. This method is widely employed in applications such as motor speed control, LED dimming, and power regulation due to its efficiency and precise control.

What is Pulse Frequency Modulation (PFM)?

Pulse Frequency Modulation (PFM) is a power regulation technique where the frequency of the pulses varies to control the output voltage or current, unlike Pulse Width Modulation (PWM) which adjusts pulse width. PFM improves efficiency in low-load conditions by reducing switching losses, making it ideal for battery-powered applications. Your device benefits from PFM by achieving longer battery life through optimized power management.

Key Differences Between PWM and PFM

Pulse Width Modulation (PWM) controls power by varying the duty cycle of a constant frequency signal, providing consistent switching frequency and stable output voltage regulation. Pulse Frequency Modulation (PFM) adjusts the switching frequency while maintaining a fixed pulse width, improving efficiency at light loads by reducing switching losses. PWM is ideal for applications requiring low noise and precise voltage control, whereas PFM suits power-saving designs with varying load conditions.

Applications of PWM in Modern Electronics

Pulse Width Modulation (PWM) is extensively used in motor control systems, power supplies, and LED dimming due to its precise voltage regulation and energy efficiency. PWM enables efficient control of power in DC-DC converters and is fundamental in embedded systems for generating analog signal approximations. Its ability to reduce power loss while maintaining signal integrity makes it ideal for applications in audio amplification and battery management systems.

Applications of PFM in Power Management

PFM (Pulse Frequency Modulation) is widely used in power management applications that require high efficiency at light loads, such as battery-powered devices and portable electronics. Your power systems benefit from PFM's ability to reduce switching losses and extend battery life by dynamically adjusting the switching frequency based on the load demand. This modulation technique excels in low-power environments where maintaining stable voltage with minimal power consumption is critical.

Efficiency Comparison: PWM vs PFM

Pulse Width Modulation (PWM) typically offers higher efficiency at steady and high-load conditions by delivering consistent switching frequencies, minimizing power loss. Pulse Frequency Modulation (PFM) improves efficiency during light-load or idle states by adjusting switching frequency, reducing switching losses and enhancing battery life. Your choice between PWM and PFM depends on load conditions, with PWM excelling in heavy-duty efficiency and PFM providing superior energy savings at lower power levels.

Advantages and Disadvantages of PWM

PWM (Pulse Width Modulation) offers precise control over power delivery, making it highly efficient for applications requiring stable voltage and current regulation. Its main advantage is maintaining consistent output with minimal electromagnetic interference, but PWM can generate higher switching losses and produce audible noise under certain loads. You should consider these trade-offs when choosing between PWM and PFM for your power management needs.

Advantages and Disadvantages of PFM

Pulse Frequency Modulation (PFM) offers improved efficiency at light loads by varying the switching frequency, reducing power loss and electromagnetic interference compared to Pulse Width Modulation (PWM). However, PFM can introduce increased output voltage ripple and noise, potentially affecting sensitive circuits requiring stable voltage. Choosing PFM benefits your design primarily in low-power applications where extending battery life and minimizing switching losses are critical.

Choosing Between PWM and PFM: Which is Better?

Choosing between PWM (Pulse Width Modulation) and PFM (Pulse Frequency Modulation) depends on the specific application requirements such as efficiency, noise, and load conditions. PWM is generally better for applications demanding constant frequency, lower output ripple, and higher load currents, while PFM excels in light-load efficiency and reduced switching losses. Engineers prioritize PWM for stable voltage regulation in power supplies, whereas PFM is favored in battery-powered devices to extend runtime.

PWM vs PFM Infographic

libmatt.com

libmatt.com