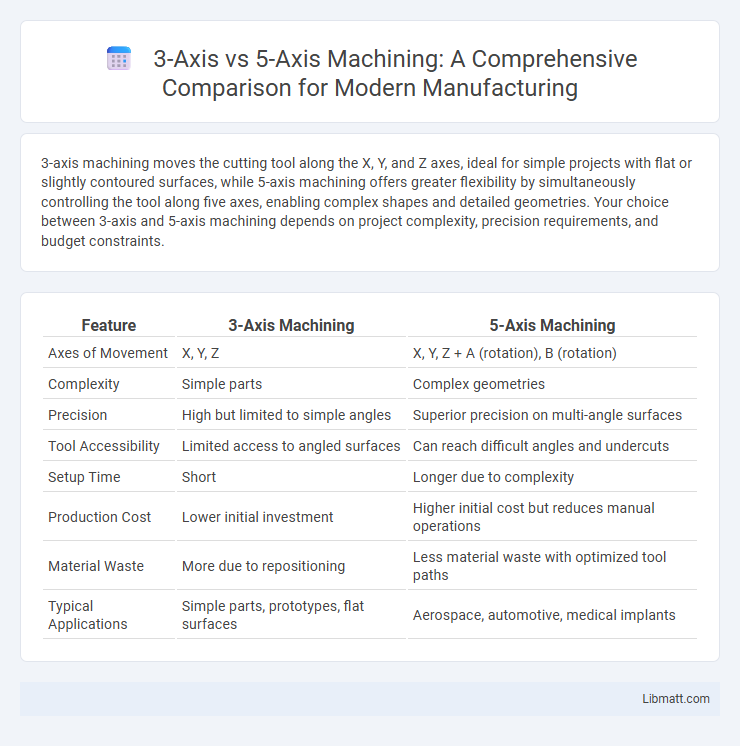

3-axis machining moves the cutting tool along the X, Y, and Z axes, ideal for simple projects with flat or slightly contoured surfaces, while 5-axis machining offers greater flexibility by simultaneously controlling the tool along five axes, enabling complex shapes and detailed geometries. Your choice between 3-axis and 5-axis machining depends on project complexity, precision requirements, and budget constraints.

Table of Comparison

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Axes of Movement | X, Y, Z | X, Y, Z + A (rotation), B (rotation) |

| Complexity | Simple parts | Complex geometries |

| Precision | High but limited to simple angles | Superior precision on multi-angle surfaces |

| Tool Accessibility | Limited access to angled surfaces | Can reach difficult angles and undercuts |

| Setup Time | Short | Longer due to complexity |

| Production Cost | Lower initial investment | Higher initial cost but reduces manual operations |

| Material Waste | More due to repositioning | Less material waste with optimized tool paths |

| Typical Applications | Simple parts, prototypes, flat surfaces | Aerospace, automotive, medical implants |

Introduction to CNC Machining

CNC machining involves automated control of machine tools with computer programming, where 3-axis machines move cutting tools along the X, Y, and Z axes, enabling precise shaping and drilling primarily on flat or simple contoured surfaces. 5-axis machining extends these capabilities by adding rotational movement along two additional axes, allowing complex geometries and intricate parts to be manufactured with higher precision and reduced setup time. The choice between 3-axis and 5-axis CNC machining depends on the complexity of the design, material requirements, and production efficiency.

What is 3-Axis Machining?

3-axis machining involves the movement of a cutting tool along three linear axes: X, Y, and Z, allowing for precise shaping of materials in a fixed orientation. This method is ideal for simpler parts with flat or prismatic surfaces, where complex angles or undercuts are not required. You can achieve efficient and cost-effective production for components that do not demand the advanced flexibility of multi-axis machining.

What is 5-Axis Machining?

5-axis machining is an advanced manufacturing process that allows a cutting tool to move simultaneously along five different axes, enabling the creation of complex and precise parts with intricate geometries. Compared to 3-axis machining, which moves in three directions (X, Y, and Z), 5-axis machining adds rotational movements around two additional axes, enhancing tool access and reducing the need for multiple setups. This technology is widely used in aerospace, automotive, and medical industries where precision, surface finish, and complex shapes are critical.

Key Differences Between 3-Axis and 5-Axis Machining

3-axis machining operates on three linear axes (X, Y, and Z), limiting tool movement to vertical and horizontal directions, making it ideal for simple, flat parts. 5-axis machining adds two rotational axes, enabling the tool or part to tilt and rotate, which allows for complex geometries, undercuts, and multi-sided machining without repositioning. Your choice between 3-axis and 5-axis machining impacts precision, speed, and the ability to produce intricate components efficiently.

Advantages of 3-Axis Machining

3-axis machining offers simplicity and cost-effectiveness, making it ideal for straightforward parts with less complex geometries. It provides faster setup times and easier programming due to limited tool movement along the X, Y, and Z axes. This approach enhances manufacturing efficiency for high-volume production, reducing machine and operational costs compared to 5-axis machining.

Advantages of 5-Axis Machining

5-axis machining offers superior precision and versatility by enabling complex geometries to be machined in a single setup, reducing the need for multiple fixtures and manual repositioning. This advanced capability enhances surface finish quality and shortens production time, making it ideal for intricate parts in aerospace, automotive, and medical industries. The extended range of motion in 5-axis machines also improves tool life and reduces wear by optimizing cutting angles and tool engagement.

Limitations of 3-Axis Machining

3-axis machining is limited by its inability to approach the workpiece from multiple angles, restricting complex geometries and intricate details. The fixed tool orientation results in increased setup times and potential inaccuracies for parts requiring undercuts or complex contours. Your production may be constrained by these limitations, especially when precision and multi-dimensional machining are critical.

Limitations of 5-Axis Machining

5-axis machining offers enhanced precision and the ability to create complex geometries, but it has limitations such as higher equipment and maintenance costs compared to 3-axis machining. The increased complexity requires skilled operators and advanced programming, which can extend setup times and increase the potential for errors. Your manufacturing process might also encounter limitations in part size and access, as some workpieces may not fit or be properly oriented within the 5-axis machine's workspace.

Applications: When to Choose 3-Axis or 5-Axis Machining

3-axis machining is ideal for simple geometries and flat surfaces, making it suitable for applications like automotive parts, basic molds, and prototyping. 5-axis machining excels in complex, contoured components such as aerospace parts, medical implants, and intricate molds, providing greater precision and flexibility. Your choice depends on the part complexity, required accuracy, and production speed, with 5-axis offering enhanced capability for detailed and multi-dimensional machining tasks.

Cost Considerations and ROI Analysis

3-axis machining typically involves lower upfront costs and simpler programming, making it ideal for small to medium production runs with straightforward geometries. In contrast, 5-axis machining requires a higher initial investment due to advanced machinery and software but offers significant ROI through reduced setups, enhanced precision, and the ability to produce complex parts in fewer operations. Businesses must weigh the cost savings of 3-axis against the efficiency and quality gains of 5-axis to maximize profitability and meet production demands.

3-axis vs 5-axis machining Infographic

libmatt.com

libmatt.com