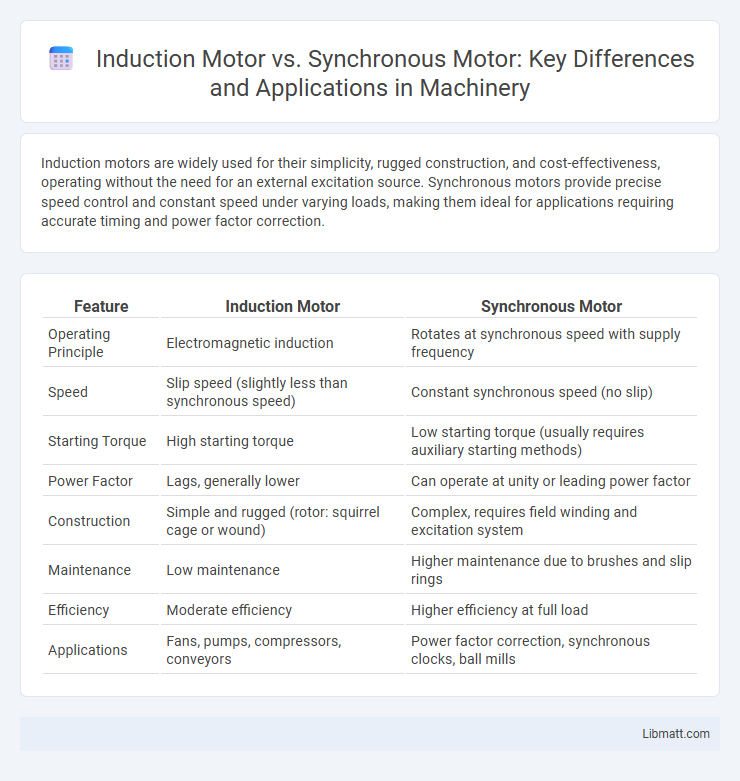

Induction motors are widely used for their simplicity, rugged construction, and cost-effectiveness, operating without the need for an external excitation source. Synchronous motors provide precise speed control and constant speed under varying loads, making them ideal for applications requiring accurate timing and power factor correction.

Table of Comparison

| Feature | Induction Motor | Synchronous Motor |

|---|---|---|

| Operating Principle | Electromagnetic induction | Rotates at synchronous speed with supply frequency |

| Speed | Slip speed (slightly less than synchronous speed) | Constant synchronous speed (no slip) |

| Starting Torque | High starting torque | Low starting torque (usually requires auxiliary starting methods) |

| Power Factor | Lags, generally lower | Can operate at unity or leading power factor |

| Construction | Simple and rugged (rotor: squirrel cage or wound) | Complex, requires field winding and excitation system |

| Maintenance | Low maintenance | Higher maintenance due to brushes and slip rings |

| Efficiency | Moderate efficiency | Higher efficiency at full load |

| Applications | Fans, pumps, compressors, conveyors | Power factor correction, synchronous clocks, ball mills |

Introduction to Induction and Synchronous Motors

Induction motors operate based on electromagnetic induction, where the rotor is induced by the stator's rotating magnetic field, leading to slip between rotor speed and synchronous speed. Synchronous motors, by contrast, run at a constant speed equal to the supply frequency, with the rotor magnetically locked in step with the stator's rotating magnetic field. These fundamental differences determine their applications, with induction motors favored for simplicity and robustness, while synchronous motors excel in precision speed control and power factor correction.

Basic Operating Principles

Induction motors operate on the principle of electromagnetic induction, where the rotor is induced by a rotating magnetic field in the stator without direct electrical connection. Synchronous motors rely on the rotor rotating at the same speed as the stator's magnetic field, maintaining constant synchronous speed through direct current excitation of the rotor winding. Understanding these basic operating principles helps you select the appropriate motor type based on speed consistency and torque requirements.

Construction Differences

Induction motors feature a rotor made of laminated iron cores with squirrel-cage conductors, while synchronous motors have rotors equipped with field windings or permanent magnets. The stator construction in both motors includes three-phase windings, but synchronous motors require additional excitation sources to create a constant magnetic field. Your choice depends on the application's construction preferences and performance needs.

Types and Variations

Induction motors are primarily classified into squirrel cage and wound rotor types, with squirrel cage being the most common due to its robustness and simplicity, while wound rotor motors offer controllable starting torque and speed variation. Synchronous motors include salient pole and cylindrical rotor (non-salient) types, designed for applications requiring precise speed and position control, often coupled with synchronous condensers for power factor correction. Both motor types have specialized versions such as single-phase and three-phase inductive motors, and synchronous brushless or permanent magnet synchronous motors to meet diverse industrial requirements.

Performance and Efficiency Comparison

Induction motors generally offer robust performance with moderate efficiency, typically ranging from 85% to 95%, making them suitable for variable-speed applications and environments with fluctuating loads. Synchronous motors, however, provide higher efficiency levels, often exceeding 95%, due to their constant speed operation and ability to correct power factor, which enhances overall system performance. Your choice between induction and synchronous motors should consider efficiency requirements and load consistency for optimal energy savings and reliable performance.

Starting Methods and Controls

Induction motors typically use direct-on-line, star-delta, or autotransformer starting methods to limit inrush current and ensure smooth acceleration, with control options including variable frequency drives (VFDs) for speed regulation. Synchronous motors require external starting mechanisms such as pony motors or variable frequency drives to bring the rotor up to synchronous speed before the motor locks in, with advanced control systems managing excitation and maintaining synchronism. Both motor types benefit from electronic controllers for precise speed, torque control, and protection against electrical faults during starting and operation.

Speed Regulation Capabilities

Induction motors exhibit slip during operation, resulting in less precise speed regulation under varying loads, typically around 2-5% speed variation. Synchronous motors maintain a constant speed equal to the supply frequency, offering superior speed regulation with near-zero slip regardless of load changes. This inherent characteristic makes synchronous motors ideal for applications requiring exact speed control, such as in precision drives and timing systems.

Applications in Industry

Induction motors dominate industrial applications such as conveyors, pumps, fans, and compressors due to their rugged construction, low cost, and ease of maintenance. Synchronous motors are preferred in industries requiring precise speed control and power factor correction, including steel mills, paper production, and large manufacturing plants. The ability of synchronous motors to operate at constant speed under varying loads makes them ideal for processes demanding high efficiency and synchronization with the power grid.

Advantages and Limitations

Induction motors offer advantages such as simple construction, robustness, low cost, and ease of maintenance, making them ideal for industrial applications with varying load conditions. Synchronous motors provide precise speed control and higher efficiency at constant speeds, suitable for applications requiring accurate timing and power factor correction. Your choice depends on the need for speed stability and control versus cost-effectiveness and durability.

Selection Criteria and Recommendations

Induction motors are preferred for applications requiring ruggedness, low cost, and simple maintenance, making them ideal for pumps, fans, and conveyors where speed variation is less critical. Synchronous motors offer precise speed control and power factor correction, suited for applications demanding constant speed under varying loads, such as compressors and generators. Your selection should consider load characteristics, speed requirements, and efficiency goals to optimize performance and operational cost.

Induction motor vs synchronous motor Infographic

libmatt.com

libmatt.com