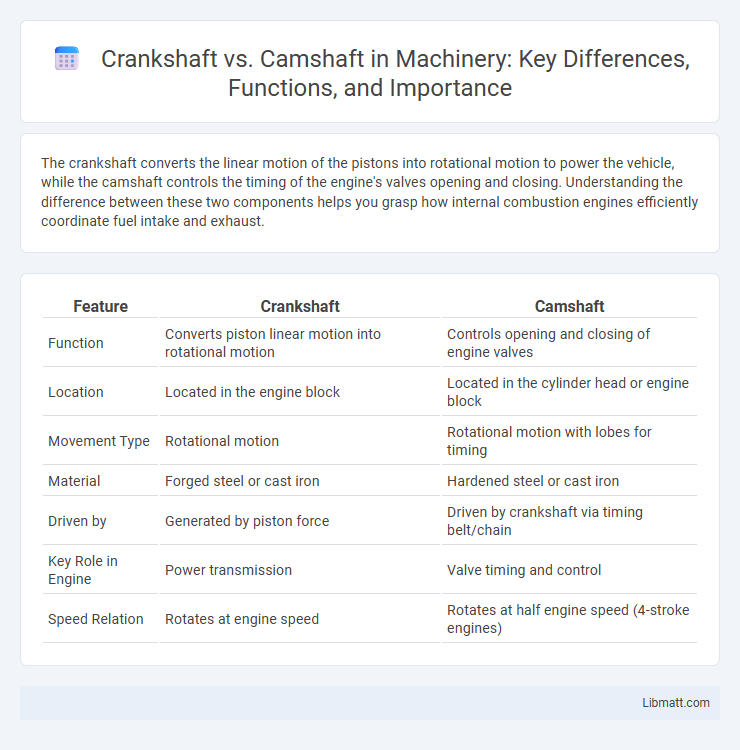

The crankshaft converts the linear motion of the pistons into rotational motion to power the vehicle, while the camshaft controls the timing of the engine's valves opening and closing. Understanding the difference between these two components helps you grasp how internal combustion engines efficiently coordinate fuel intake and exhaust.

Table of Comparison

| Feature | Crankshaft | Camshaft |

|---|---|---|

| Function | Converts piston linear motion into rotational motion | Controls opening and closing of engine valves |

| Location | Located in the engine block | Located in the cylinder head or engine block |

| Movement Type | Rotational motion | Rotational motion with lobes for timing |

| Material | Forged steel or cast iron | Hardened steel or cast iron |

| Driven by | Generated by piston force | Driven by crankshaft via timing belt/chain |

| Key Role in Engine | Power transmission | Valve timing and control |

| Speed Relation | Rotates at engine speed | Rotates at half engine speed (4-stroke engines) |

Introduction to Crankshaft and Camshaft

The crankshaft converts the linear motion of pistons into rotational motion to drive the vehicle's wheels, playing a critical role in engine performance and power delivery. The camshaft controls the timing and operation of the engine's valves, ensuring precise air-fuel intake and exhaust gas expulsion for efficient combustion. Both components are essential to internal combustion engines, with the crankshaft typically situated in the engine block and the camshaft located in the cylinder head or engine block depending on the engine design.

Basic Functions Explained

The crankshaft converts the linear motion of pistons into rotational motion to power the vehicle's drivetrain, while the camshaft controls the opening and closing of valves for proper air-fuel mixture and exhaust flow. The crankshaft relies on the pistons' up-and-down movement to generate torque, and the camshaft synchronizes valve timing with the engine cycle for optimal performance. Understanding the distinct roles of your engine's crankshaft and camshaft helps in diagnosing mechanical issues and maintaining efficient engine operation.

Structural Differences

The crankshaft is a robust, irregularly shaped component with offset crankpins designed to convert linear piston motion into rotational motion, made typically from forged steel or cast iron for high strength. The camshaft features cylindrical shape with cam lobes strategically placed along its length to control valve timing and lift, crafted from cast iron or billet steel for precision and wear resistance. Structurally, the crankshaft operates under torsional stress while the camshaft is designed for rotational motion synchronization with the crankshaft via timing chains or belts.

Location in the Engine

The crankshaft is located at the bottom of the engine block, connected directly to the pistons via connecting rods, converting linear piston motion into rotational motion. The camshaft is situated above the crankshaft, often within the cylinder head in overhead cam designs, controlling the opening and closing of the engine's valves through its lobes. Precise positioning of the camshaft in relation to the crankshaft is critical to ensure accurate valve timing for optimal engine performance.

Role in Engine Timing

The crankshaft converts the linear motion of pistons into rotational motion, driving the engine's power output and synchronizing with the camshaft to ensure precise engine timing. The camshaft controls the opening and closing of the engine's intake and exhaust valves, which is critical for the correct air-fuel mixture and exhaust flow. Your engine's optimal performance depends on the exact coordination between the crankshaft and camshaft to maintain accurate valve timing throughout the combustion cycle.

Materials and Manufacturing

Crankshafts are typically made from forged steel or cast iron to withstand high stress and fatigue, while camshafts are often manufactured from cast iron, steel alloys, or billet steel for durability and precision. Advanced manufacturing techniques like CNC machining and heat treatment enhance the performance and longevity of both components by improving strength and wear resistance. Your engine's efficiency depends on the quality and material properties of these shafts, as they endure constant mechanical and thermal loads during operation.

Common Issues and Failures

Crankshaft and camshaft failures often stem from wear and tear, lack of lubrication, or improper maintenance, leading to issues like bearing damage, shaft misalignment, and timing problems. Crankshaft problems may include cracks or warping due to excessive force, while camshaft issues often involve worn lobes or camshaft bearings causing poor engine performance. To protect your engine, regular oil changes and timely inspections are crucial to detecting early signs of crankshaft or camshaft damage.

Maintenance and Longevity

Crankshaft maintenance involves regular inspections for cracks and bearing wear to ensure long-term engine performance, while camshafts require periodic lubrication and timing checks to prevent wear and maintain valve operation. Proper oil quality and timely replacement extend the lifespan of both components, reducing costly repairs and enhancing engine reliability. Your engine's overall health depends on balanced upkeep of the crankshaft and camshaft to maximize durability and efficiency.

Performance Impact

The crankshaft directly influences engine torque and power delivery by converting linear piston motion into rotational force, crucial for overall performance. The camshaft controls valve timing and lift, optimizing air-fuel mixture intake and exhaust flow, which significantly affects engine efficiency and horsepower. Precise synchronization between crankshaft and camshaft ensures maximum combustion efficiency, enhancing acceleration, fuel economy, and engine responsiveness.

Crankshaft vs Camshaft: Key Differences

Crankshaft vs camshaft key differences lie in their functions and locations within the engine; the crankshaft converts the linear motion of pistons into rotational motion to drive the vehicle, while the camshaft controls the opening and closing of valves for air-fuel mixture and exhaust gases. The crankshaft is connected to the pistons via connecting rods and rotates at engine speed, whereas the camshaft operates at half the crankshaft speed and is linked through a timing belt or chain. Understanding these distinctions helps you diagnose engine issues and optimize vehicle maintenance effectively.

Crankshaft vs camshaft Infographic

libmatt.com

libmatt.com