Pressure die casting uses high-pressure to force molten metal into a mold, resulting in precise, complex shapes with excellent surface finish and dimensional accuracy. Gravity die casting relies on gravity to fill the mold, offering cost-effective production for simpler, thicker parts but with less precision and surface quality compared to pressure die casting.

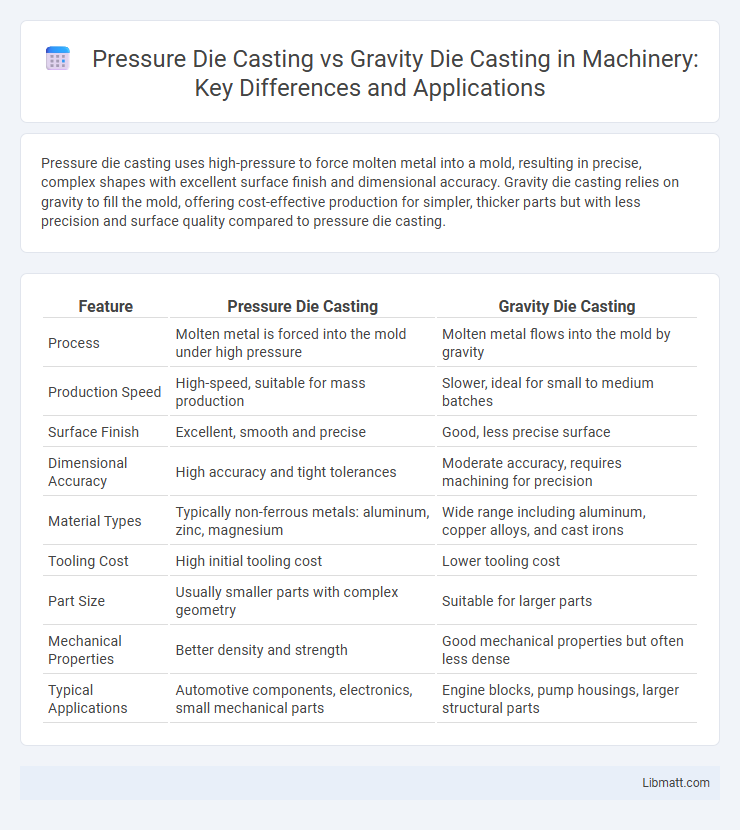

Table of Comparison

| Feature | Pressure Die Casting | Gravity Die Casting |

|---|---|---|

| Process | Molten metal is forced into the mold under high pressure | Molten metal flows into the mold by gravity |

| Production Speed | High-speed, suitable for mass production | Slower, ideal for small to medium batches |

| Surface Finish | Excellent, smooth and precise | Good, less precise surface |

| Dimensional Accuracy | High accuracy and tight tolerances | Moderate accuracy, requires machining for precision |

| Material Types | Typically non-ferrous metals: aluminum, zinc, magnesium | Wide range including aluminum, copper alloys, and cast irons |

| Tooling Cost | High initial tooling cost | Lower tooling cost |

| Part Size | Usually smaller parts with complex geometry | Suitable for larger parts |

| Mechanical Properties | Better density and strength | Good mechanical properties but often less dense |

| Typical Applications | Automotive components, electronics, small mechanical parts | Engine blocks, pump housings, larger structural parts |

Introduction to Die Casting Methods

Pressure die casting forces molten metal into a steel mold under high pressure, resulting in precise, complex shapes with excellent surface finish and dimensional accuracy. Gravity die casting uses gravity to fill the mold, producing parts with good mechanical properties and less internal stress, often suited for larger, simpler components. Your choice depends on the required detail, production volume, and material properties for the casting application.

Overview of Pressure Die Casting

Pressure die casting uses high-pressure injection of molten metal into a steel mold, enabling rapid production of complex, high-precision metal parts with excellent surface finish and dimensional accuracy. This method is ideal for mass manufacturing of components from non-ferrous metals like aluminum, zinc, and magnesium due to its efficiency and repeatability. You benefit from faster cycle times and superior mechanical properties compared to gravity die casting, which relies on gravity to fill the mold.

Overview of Gravity Die Casting

Gravity die casting involves pouring molten metal into a permanent mold using gravity, resulting in precise, high-quality metal components with excellent surface finish and dimensional accuracy. This method is ideal for medium to high production runs of non-ferrous metals like aluminum, brass, and bronze, offering superior mechanical properties and reduced porosity compared to sand casting. Your choice of gravity die casting can enhance the strength and durability of components, making it suitable for automotive and aerospace applications.

Key Differences Between Pressure and Gravity Die Casting

Pressure die casting forces molten metal into a mold cavity under high pressure, resulting in precise, complex shapes with excellent surface finish and tight tolerances. Gravity die casting relies on gravity to fill the mold, producing parts with a coarser texture and less dimensional accuracy, ideal for simpler, larger components. Your choice depends on the required detail, production volume, and material properties, with pressure die casting offering faster cycles and higher repeatability compared to gravity die casting.

Material Suitability Comparison

Pressure die casting excels with non-ferrous metals such as aluminum, zinc, and magnesium due to its high-pressure injection process, which ensures fine detail and superior surface finish. Gravity die casting is more suitable for alloys with higher melting points like copper and brass, enabling better control over solidification and reduced porosity. Both methods offer distinct material compatibilities, with pressure die casting favoring lightweight, high-volume production and gravity die casting ideal for denser, complex castings with enhanced mechanical properties.

Advantages of Pressure Die Casting

Pressure die casting offers superior precision and dimensional accuracy compared to gravity die casting, enabling the production of complex shapes with intricate details and thin walls. The process significantly reduces porosity and improves mechanical properties, resulting in stronger, more durable components suitable for high-stress applications. High-speed production cycles and automation in pressure die casting enhance efficiency and cost-effectiveness for large-scale manufacturing.

Benefits of Gravity Die Casting

Gravity die casting offers superior dimensional accuracy and surface finish compared to pressure die casting, making it ideal for producing complex, high-quality parts with minimal post-processing. It enables better control over metal solidification, reducing porosity and improving mechanical properties such as tensile strength and fatigue resistance. The process is also more cost-effective for medium-sized production runs due to lower tooling costs and simpler equipment requirements.

Common Defects and Quality Control

Pressure die casting often experiences defects such as porosity, cold shuts, and misruns due to high injection speeds and rapid cooling, requiring rigorous process control and real-time monitoring to maintain quality. Gravity die casting commonly faces defects like cold shuts, shrinkage porosity, and surface blowholes, necessitating precise mold design and controlled solidification to minimize issues. Your quality control strategy should incorporate non-destructive testing and consistent parameter adjustments tailored to these methods to ensure defect-free castings.

Application Areas for Each Casting Process

Pressure die casting is widely used in automotive, aerospace, and electronics industries where high precision and complex shapes are essential for components like engine blocks, housings, and connectors. Gravity die casting is ideal for producing larger, simpler parts such as aerospace structural components, marine hardware, and power generation equipment, where design flexibility and reduced porosity are priorities. Choosing the right method depends on your need for production volume, component complexity, and material properties.

Choosing the Right Die Casting Method

Choosing the right die casting method depends on your project's precision, production volume, and material requirements. Pressure die casting offers high accuracy, rapid production cycles, and excellent surface finish, making it ideal for complex, high-volume parts. Gravity die casting provides better control over metal flow and is suited for larger components with thicker walls, offering cost-effective production for lower volumes.

Pressure die casting vs gravity die casting Infographic

libmatt.com

libmatt.com