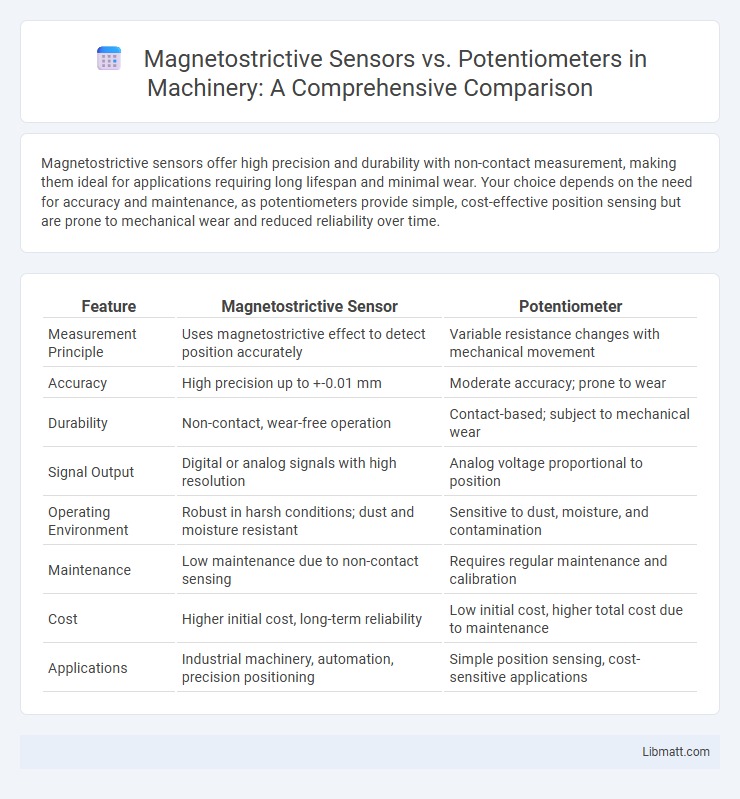

Magnetostrictive sensors offer high precision and durability with non-contact measurement, making them ideal for applications requiring long lifespan and minimal wear. Your choice depends on the need for accuracy and maintenance, as potentiometers provide simple, cost-effective position sensing but are prone to mechanical wear and reduced reliability over time.

Table of Comparison

| Feature | Magnetostrictive Sensor | Potentiometer |

|---|---|---|

| Measurement Principle | Uses magnetostrictive effect to detect position accurately | Variable resistance changes with mechanical movement |

| Accuracy | High precision up to +-0.01 mm | Moderate accuracy; prone to wear |

| Durability | Non-contact, wear-free operation | Contact-based; subject to mechanical wear |

| Signal Output | Digital or analog signals with high resolution | Analog voltage proportional to position |

| Operating Environment | Robust in harsh conditions; dust and moisture resistant | Sensitive to dust, moisture, and contamination |

| Maintenance | Low maintenance due to non-contact sensing | Requires regular maintenance and calibration |

| Cost | Higher initial cost, long-term reliability | Low initial cost, higher total cost due to maintenance |

| Applications | Industrial machinery, automation, precision positioning | Simple position sensing, cost-sensitive applications |

Introduction to Magnetostrictive Sensors and Potentiometers

Magnetostrictive sensors operate based on the magnetostrictive effect, converting mechanical displacement into electrical signals through variations in magnetic fields, enabling precise, non-contact position measurements. Potentiometers function as variable resistors that adjust voltage output corresponding to shaft or slider displacement, offering direct, analog position feedback with a simpler electrical design. Both devices serve in position sensing applications, but magnetostrictive sensors excel in durability and accuracy for industrial automation, while potentiometers provide cost-effective, straightforward solutions for less demanding environments.

Operating Principles: How Each Sensor Works

Magnetostrictive sensors operate based on the interaction between magnetic fields and torsional strain pulses generated within a waveguide when an electric current induces magnetic fields; the time delay of the pulse traveling along the waveguide determines position or displacement. Potentiometers function by translating mechanical position into an electrical voltage output through a resistive element contacted by a sliding wiper, allowing measurement of angular or linear movement. Unlike potentiometers, magnetostrictive sensors provide non-contact, high-precision measurements with longer lifespan due to lack of mechanical wear.

Measurement Accuracy and Precision

Magnetostrictive sensors offer higher measurement accuracy and precision compared to potentiometers due to their non-contact sensing technology, minimizing wear and signal degradation over time. The precise detection of magnetic field changes allows magnetostrictive sensors to deliver repeatability within microns, outperforming the mechanical contact variability inherent in potentiometers. Your choice for applications demanding consistent, high-resolution displacement data should favor magnetostrictive sensors for enhanced reliability.

Range and Application Suitability

Magnetostrictive sensors offer precise, long-range position measurements up to several meters, making them ideal for industrial automation and heavy machinery applications requiring high accuracy and durability. Potentiometers typically provide shorter measurement ranges, usually a few centimeters to a meter, and suit simpler, low-cost applications such as user controls and basic position feedback. The extended range and robust performance of magnetostrictive sensors outperform potentiometers in environments where precision and harsh conditions are critical.

Durability and Environmental Resistance

Magnetostrictive sensors offer superior durability and environmental resistance compared to potentiometers, as they are non-contact devices with solid-state construction that resists wear and corrosion. These sensors perform reliably under extreme temperatures, moisture, dust, and vibration, making them ideal for harsh industrial environments. In contrast, potentiometers, with their mechanical sliding contacts, suffer from wear, contamination, and reduced lifespan in demanding conditions.

Installation and Maintenance Requirements

Magnetostrictive sensors offer precise, non-contact measurement with minimal installation complexity, requiring alignment along a metal waveguide and simple electrical connections, while potentiometers need physical contact and careful mechanical mounting to avoid wear and calibration drift. You benefit from reduced maintenance in magnetostrictive sensors since they have no sliding parts, leading to less frequent replacements and reliable long-term performance. In contrast, potentiometers demand regular maintenance due to mechanical wear, sensitivity to dust and debris, and the necessity for periodic recalibration.

Signal Output and Integration Capabilities

Magnetostrictive sensors provide high-resolution, linear analog or digital signal outputs, offering greater precision and noise immunity compared to potentiometers, which generate variable resistance signals prone to wear and drift. Integration capabilities of magnetostrictive sensors include easy interfacing with digital control systems via protocols like SSI or analog voltage/current, while potentiometers require additional signal conditioning and are less compatible with modern automation systems. The robust, contactless sensing method of magnetostrictive sensors enhances longevity and reliability in industrial and automotive applications versus the mechanical wear limitations of potentiometers.

Cost Considerations and Economic Factors

Magnetostrictive sensors generally have a higher upfront cost compared to potentiometers due to advanced materials and precise calibration requirements. Potentiometers offer a more cost-effective solution for basic linear position sensing but may incur greater long-term maintenance expenses from wear and signal degradation. The total economic value of magnetostrictive sensors often aligns with applications demanding higher accuracy and durability despite their initial premium.

Industry Applications: Use Cases Compared

Magnetostrictive sensors excel in industrial automation and robotics due to their high precision and durability in harsh environments, commonly used for position feedback and linear displacement measurement. Potentiometers find frequent use in consumer electronics, automotive controls, and simple manual adjustments where cost-effectiveness and ease of integration are prioritized. Your choice between the two depends on application requirements: magnetostrictive sensors for long-life, non-contact measurement in demanding settings, and potentiometers for straightforward, low-cost variable resistance sensing.

Choosing Between Magnetostrictive Sensors and Potentiometers

Choosing between magnetostrictive sensors and potentiometers depends on your application's precision, durability, and environmental requirements. Magnetostrictive sensors offer highly accurate, non-contact position measurement with excellent resistance to wear, making them ideal for harsh industrial environments. Potentiometers provide a cost-effective, simple solution for position sensing but may suffer from wear and reduced accuracy over time in demanding conditions.

Magnetostrictive sensor vs potentiometer Infographic

libmatt.com

libmatt.com