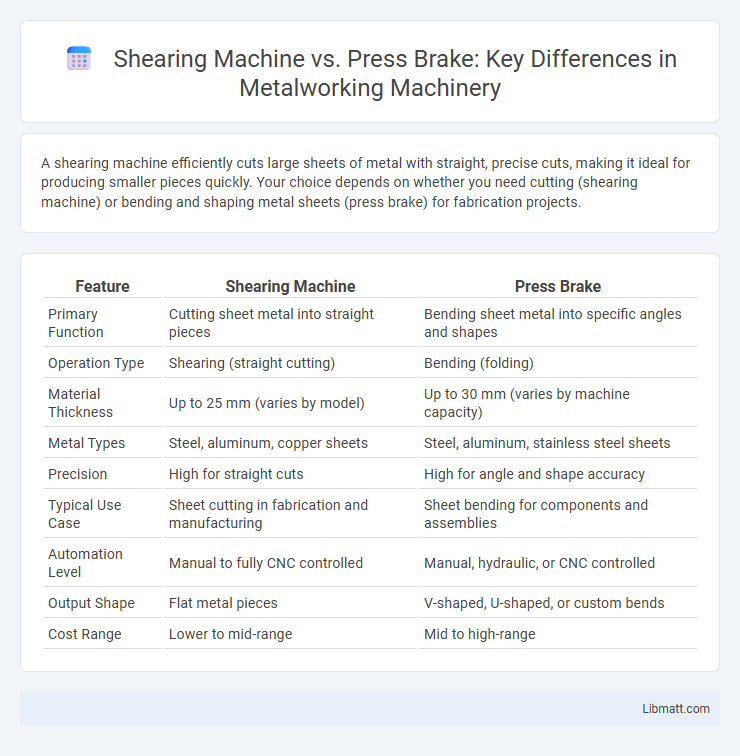

A shearing machine efficiently cuts large sheets of metal with straight, precise cuts, making it ideal for producing smaller pieces quickly. Your choice depends on whether you need cutting (shearing machine) or bending and shaping metal sheets (press brake) for fabrication projects.

Table of Comparison

| Feature | Shearing Machine | Press Brake |

|---|---|---|

| Primary Function | Cutting sheet metal into straight pieces | Bending sheet metal into specific angles and shapes |

| Operation Type | Shearing (straight cutting) | Bending (folding) |

| Material Thickness | Up to 25 mm (varies by model) | Up to 30 mm (varies by machine capacity) |

| Metal Types | Steel, aluminum, copper sheets | Steel, aluminum, stainless steel sheets |

| Precision | High for straight cuts | High for angle and shape accuracy |

| Typical Use Case | Sheet cutting in fabrication and manufacturing | Sheet bending for components and assemblies |

| Automation Level | Manual to fully CNC controlled | Manual, hydraulic, or CNC controlled |

| Output Shape | Flat metal pieces | V-shaped, U-shaped, or custom bends |

| Cost Range | Lower to mid-range | Mid to high-range |

Introduction to Shearing Machines and Press Brakes

Shearing machines are industrial tools designed to cut large metal sheets with precision using a straight blade, making them essential for rapid, clean cuts in fabrication processes. Press brakes use a punch and die to bend and shape metal sheets into specific angles and forms, providing versatility for custom metalworking projects. Your choice between these machines depends on whether you need accurate cutting or precise bending for your metal fabrication tasks.

Core Functions and Applications

Shearing machines excel at cutting large sheets of metal into smaller, uniform pieces with precise straight cuts, making them essential for tasks requiring speed and accuracy in sheet metal fabrication. Press brakes are designed to bend and shape metal by clamping the workpiece between a matching punch and die, enabling the creation of complex angles and folds critical in manufacturing components like brackets and panels. Your choice between a shearing machine and a press brake should depend on whether your project demands cutting or bending operations for efficient metalworking outcomes.

Key Components and Working Principles

Shearing machines feature a fixed and moving blade that slices metal sheets through a guillotine action, driven by mechanical or hydraulic power, focusing on precise straight cuts. Press brakes utilize a punch and die setup, applying downward force to bend metal sheets into specific angles or shapes, controlled by hydraulic or mechanical systems. Key components of shearing machines include the blade, clutch, and motor, while press brakes consist of the ram, bed, punch, die, and CNC control for accurate bending operations.

Material Types and Thickness Capabilities

Shearing machines excel at cutting sheet metals like steel, aluminum, and copper up to medium thicknesses, typically ranging from 1mm to 25mm depending on the machine's tonnage. Press brakes offer superior versatility for bending and shaping various materials including stainless steel, carbon steel, and aluminum, and can handle thicknesses from thin gauges up to 50mm or more. Your choice depends on the precision and complexity of bends versus straight cuts required for the specific material thickness and type in your project.

Accuracy and Tolerance Comparison

Shearing machines deliver cuts with moderate accuracy, typically maintaining tolerances around +-0.5 mm, suitable for straight-line trimming and simple shapes. Press brakes provide higher precision bending with tight tolerances often within +-0.1 mm, ideal for complex, angled, or contoured metalwork requiring exact dimensions. Your choice depends on whether cutting accuracy or bending tolerance is critical for your project's success.

Speed and Production Efficiency

Shearing machines offer high-speed cutting capabilities ideal for straight-line cuts, enabling rapid processing of large sheets and boosting production efficiency in mass fabrication. Press brakes provide versatility with precise bending operations but generally operate at slower cycle times due to setup adjustments and complex bending sequences. Choosing between the two depends on your production demands: shearing machines excel in fast material separation, while press brakes optimize efficiency in forming accurate bends.

Maintenance and Durability

Shearing machines require regular blade sharpening and lubrication to maintain cutting precision and prevent wear, while press brakes need frequent inspection of hydraulic systems and back gauge components to ensure bending accuracy and avoid mechanical failure. The durability of shearing machines depends heavily on the quality of blade materials and support structures, whereas press brakes benefit from robust frame construction and advanced control systems that enhance longevity under heavy-duty operations. Proper preventive maintenance for both machines extends service life, reduces downtime, and preserves optimal performance in metal fabrication environments.

Safety Features and Considerations

Shearing machines incorporate safety features such as blade guards, two-hand control systems, and emergency stop buttons to prevent accidental injuries during metal cutting processes. Press brakes prioritize operator safety with light curtains, pressure-sensitive foot pedals, and anti-crush devices to reduce the risk of hand injuries while bending metal sheets. Both machines require strict adherence to safety protocols, including proper training and regular maintenance, to ensure optimal protection in industrial environments.

Cost Analysis and Investment Value

Shearing machines generally offer a lower initial cost compared to press brakes, making them a cost-effective option for straight cutting applications. Press brakes provide higher versatility and precision for bending and forming metal, which can lead to greater long-term investment value for complex fabrication needs. Your decision should consider project requirements and volume to balance upfront costs with potential returns on productivity and flexibility.

Selecting the Right Machine for Your Needs

Choosing between a shearing machine and a press brake depends on the specific metal fabrication task; shearing machines excel at cutting straight lines in sheet metal with high precision and speed, while press brakes are ideal for bending and forming complex shapes. Consider factors such as material thickness, production volume, and required angles--press brakes handle thicker materials and intricate bends better, whereas shearing machines provide efficient, clean cuts for large quantities. Evaluating your workflow requirements and desired outcomes ensures selecting the right equipment maximizes efficiency and product quality.

Shearing machine vs press brake Infographic

libmatt.com

libmatt.com