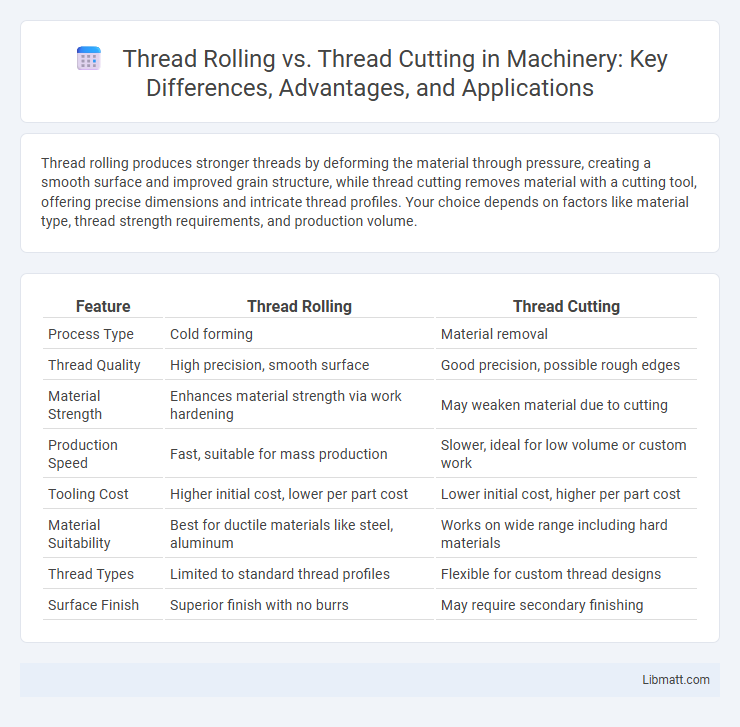

Thread rolling produces stronger threads by deforming the material through pressure, creating a smooth surface and improved grain structure, while thread cutting removes material with a cutting tool, offering precise dimensions and intricate thread profiles. Your choice depends on factors like material type, thread strength requirements, and production volume.

Table of Comparison

| Feature | Thread Rolling | Thread Cutting |

|---|---|---|

| Process Type | Cold forming | Material removal |

| Thread Quality | High precision, smooth surface | Good precision, possible rough edges |

| Material Strength | Enhances material strength via work hardening | May weaken material due to cutting |

| Production Speed | Fast, suitable for mass production | Slower, ideal for low volume or custom work |

| Tooling Cost | Higher initial cost, lower per part cost | Lower initial cost, higher per part cost |

| Material Suitability | Best for ductile materials like steel, aluminum | Works on wide range including hard materials |

| Thread Types | Limited to standard thread profiles | Flexible for custom thread designs |

| Surface Finish | Superior finish with no burrs | May require secondary finishing |

Introduction to Thread Rolling and Thread Cutting

Thread rolling forms threads by plastically deforming the material, creating stronger and smoother threads with enhanced fatigue resistance. Thread cutting removes material using a cutting tool to produce precise thread profiles, typically used for harder metals or customized thread shapes. Your choice between thread rolling and thread cutting depends on factors like material type, production volume, and required thread strength.

Understanding Thread Rolling: Process and Benefits

Thread rolling is a cold-forming process that creates threads by pressing a hardened die against a cylindrical blank, resulting in increased material strength and improved surface finish compared to thread cutting. This method offers superior thread integrity due to grain flow alignment and produces minimal waste, enhancing both durability and environmental efficiency. You can benefit from thread rolling through faster production rates and greater consistency in thread dimensions, making it ideal for high-volume manufacturing.

Exploring Thread Cutting: Techniques and Applications

Thread cutting involves removing material to create precise screw threads, utilizing tools like single-point cutters or taps. This technique is ideal for producing custom or complex thread profiles on harder materials where thread rolling is unsuitable. Your choice of thread cutting ensures high accuracy and is widely applied in manufacturing aerospace components and specialized fasteners.

Key Differences Between Thread Rolling and Thread Cutting

Thread rolling forms threads by plastically deforming the material using hardened dies, resulting in stronger, smoother threads with enhanced surface finish and increased tensile strength. Thread cutting removes material using cutting tools or taps, producing precise, sharp threads but often with a rougher surface and potential material stress. Unlike thread rolling, which is a cold-forming process suitable for high-volume production, thread cutting is versatile for various thread sizes and materials but typically slower and less durable.

Material Suitability for Each Threading Method

Thread rolling is ideal for ductile materials like aluminum, brass, and low to medium carbon steels due to its cold-forming process, which enhances surface finish and increases thread strength. Thread cutting is suitable for harder or brittle materials such as stainless steel, tool steels, and cast iron, where material deformation is minimal and precision threading is required. Your choice depends on the material's hardness and ductility to ensure optimal thread quality and tool life.

Dimensional Accuracy and Surface Finish Comparison

Thread rolling produces superior dimensional accuracy by plastically deforming the material, resulting in uniform thread profiles with tight tolerances and enhanced material strength. Thread cutting removes material, often introducing microscopic irregularities that can lead to slightly less precise thread dimensions and a rougher surface finish. The cold-working effect of thread rolling also yields smoother surfaces with improved fatigue resistance compared to the comparatively coarse finish typical of thread cutting processes.

Production Speed and Cost Implications

Thread rolling offers significantly faster production speeds compared to thread cutting due to its non-cutting deformation process, enabling rapid mass production with minimal cycle times. The cost implications favor thread rolling as it reduces tooling wear and material waste, resulting in lower operational expenses and higher efficiency, especially in high-volume manufacturing. Your choice between these methods should consider thread quality requirements and production volume to optimize speed and cost-effectiveness.

Tool Wear and Maintenance Considerations

Thread rolling produces minimal tool wear due to its cold-forming process, which deforms rather than removes material, resulting in longer tool life and lower maintenance requirements. In contrast, thread cutting involves material removal through shear forces, leading to faster tool wear, frequent sharpening, and replacement to maintain precision. Maintenance strategies for thread rolling tools emphasize periodic inspection and lubrication, while thread cutting tools require regular reconditioning and monitoring of cutting edges to prevent tool failure.

Choosing the Right Threading Method for Your Project

Thread rolling produces stronger, more precise threads by deforming the material without removing it, making it ideal for high-volume production and fatigue-resistant applications. Thread cutting removes material to form threads, offering greater flexibility for custom or low-volume projects and accommodating a wider range of materials. Selecting the appropriate threading method depends on factors such as material type, production volume, thread strength requirements, and desired surface finish.

Future Trends in Thread Manufacture

Future trends in thread manufacture emphasize increased adoption of thread rolling due to its superior material strength, surface finish, and efficiency compared to thread cutting. Advancements in CNC technology and automation enhance precision and reduce production time for rolled threads, meeting demands for high-volume manufacturing in aerospace and automotive industries. Sustainable practices also drive preference for thread rolling, minimizing waste and improving tool life relative to traditional thread cutting methods.

Thread rolling vs thread cutting Infographic

libmatt.com

libmatt.com