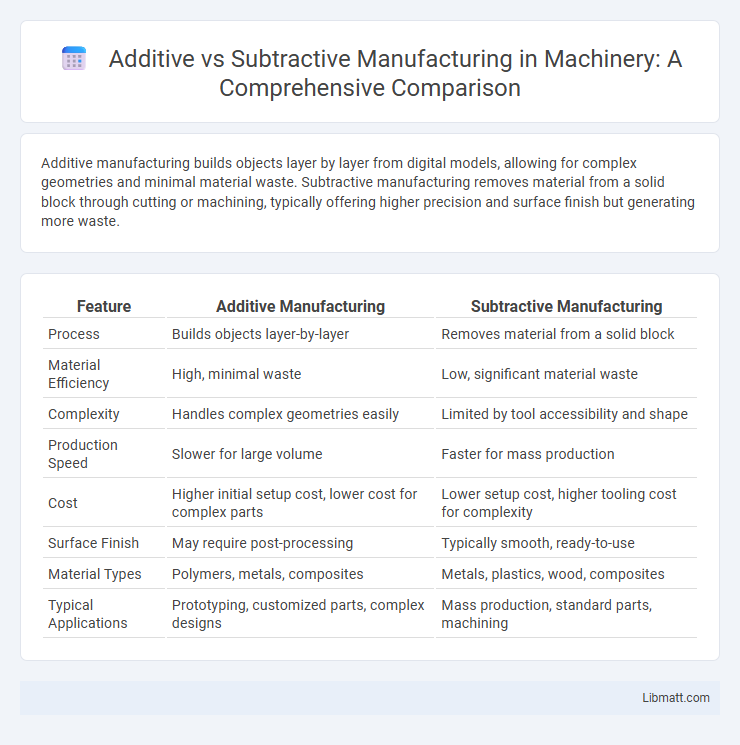

Additive manufacturing builds objects layer by layer from digital models, allowing for complex geometries and minimal material waste. Subtractive manufacturing removes material from a solid block through cutting or machining, typically offering higher precision and surface finish but generating more waste.

Table of Comparison

| Feature | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Builds objects layer-by-layer | Removes material from a solid block |

| Material Efficiency | High, minimal waste | Low, significant material waste |

| Complexity | Handles complex geometries easily | Limited by tool accessibility and shape |

| Production Speed | Slower for large volume | Faster for mass production |

| Cost | Higher initial setup cost, lower cost for complex parts | Lower setup cost, higher tooling cost for complexity |

| Surface Finish | May require post-processing | Typically smooth, ready-to-use |

| Material Types | Polymers, metals, composites | Metals, plastics, wood, composites |

| Typical Applications | Prototyping, customized parts, complex designs | Mass production, standard parts, machining |

Introduction to Additive and Subtractive Manufacturing

Additive manufacturing builds objects layer by layer using materials like plastics or metals, enabling complex geometries and minimal waste. Subtractive manufacturing removes material from a solid block through processes such as milling or turning, offering high precision and surface finish. Understanding these methods helps you select the right technology based on design complexity, material efficiency, and manufacturing goals.

Defining Additive Manufacturing

Additive Manufacturing (AM) is a process that creates objects by layering materials based on digital 3D models, contrasting with subtractive manufacturing which removes material from a solid block. Common AM technologies include Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA), enabling complex geometries and material efficiency. This method enhances customization, reduces waste, and accelerates prototyping in industries like aerospace, automotive, and healthcare.

Understanding Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block through processes like milling, turning, or drilling to create precise parts, ensuring high accuracy and smooth surface finishes. It is ideal for producing complex geometries from materials such as metals, plastics, and composites, especially when tight tolerances are required. Understanding this method helps your production team select the best approach for durability, precision, and cost-effective fabrication.

Core Principles and Processes

Additive manufacturing builds objects layer by layer using materials such as plastics, metals, or resins, enabling complex geometries and reduced waste through precise material deposition. Subtractive manufacturing removes material from a solid block through processes like milling, turning, or drilling, offering high accuracy and smooth surface finishes but often generating more waste. Core principles of additive involve digital 3D modeling and controlled material fusion, while subtractive relies on cutting tools guided by CNC programming to shape parts.

Material Range and Compatibility

Additive manufacturing supports a broad range of materials, including polymers, metals, ceramics, and composites, allowing complex geometries with minimal waste. Subtractive manufacturing primarily utilizes metals, plastics, and wood, but material compatibility depends on tooling and machine capabilities, often limiting intricate shapes. The choice between additive and subtractive methods hinges on material-specific requirements and the desired precision in the final product.

Precision and Surface Finish Comparisons

Additive manufacturing offers high precision with complex geometries achieved layer by layer, yet typically results in rougher surface finishes requiring post-processing. Subtractive manufacturing excels in delivering superior surface finishes and tight tolerances due to material removal from a solid block using CNC machining. Your choice depends on the required detail and finish quality, balancing the complexity of parts with the finishing demands.

Speed and Production Efficiency

Additive manufacturing offers faster prototyping and reduced lead times by building parts layer-by-layer directly from digital models, minimizing setup and tooling requirements. Subtractive manufacturing provides efficient mass production with high precision once tooling is established but involves longer initial setup and material waste. Speed and production efficiency depend on part complexity, volume, and customization needs, with additive excelling in rapid, flexible production and subtractive in high-volume, repeatable tasks.

Cost Analysis and Resource Utilization

Additive manufacturing reduces material waste by building parts layer-by-layer, resulting in lower raw material costs compared to subtractive manufacturing, which removes excess material through cutting or milling. Although initial equipment investment for additive processes can be high, operational costs decrease due to minimal tooling requirements and reduced labor intensity. Subtractive manufacturing often demands more energy and materials, leading to higher expenses in large-scale production and resource consumption.

Applications in Modern Industries

Additive manufacturing is widely used in aerospace for producing lightweight, complex components such as turbine blades and structural parts with reduced material waste. Subtractive manufacturing remains essential in automotive and industrial sectors for creating high-precision metal parts like engine blocks and molds through milling and turning processes. Medical industries leverage additive manufacturing to customize prosthetics and implants, while subtractive techniques ensure tight tolerances in surgical instruments and equipment.

Future Trends and Emerging Technologies

Future trends in additive manufacturing emphasize advanced materials, such as sustainable composites and high-performance alloys, while integrating AI-driven process optimization to enhance precision and reduce waste. Subtractive manufacturing is evolving through automation, robotics, and hybrid systems combining both additive and subtractive techniques for greater efficiency and flexibility. Your production capabilities can benefit from emerging technologies like 3D metal printing and real-time quality monitoring, shaping the next generation of manufacturing innovation.

Additive vs subtractive manufacturing Infographic

libmatt.com

libmatt.com