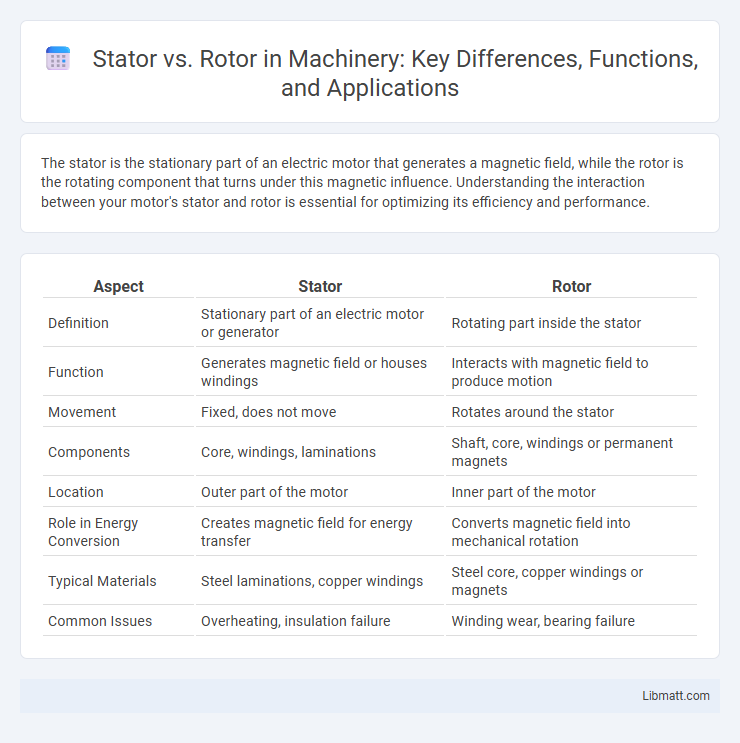

The stator is the stationary part of an electric motor that generates a magnetic field, while the rotor is the rotating component that turns under this magnetic influence. Understanding the interaction between your motor's stator and rotor is essential for optimizing its efficiency and performance.

Table of Comparison

| Aspect | Stator | Rotor |

|---|---|---|

| Definition | Stationary part of an electric motor or generator | Rotating part inside the stator |

| Function | Generates magnetic field or houses windings | Interacts with magnetic field to produce motion |

| Movement | Fixed, does not move | Rotates around the stator |

| Components | Core, windings, laminations | Shaft, core, windings or permanent magnets |

| Location | Outer part of the motor | Inner part of the motor |

| Role in Energy Conversion | Creates magnetic field for energy transfer | Converts magnetic field into mechanical rotation |

| Typical Materials | Steel laminations, copper windings | Steel core, copper windings or magnets |

| Common Issues | Overheating, insulation failure | Winding wear, bearing failure |

Introduction to Stator and Rotor

The stator is the stationary part of an electric motor or generator, comprising coils of wire that create a magnetic field when energized. The rotor is the rotating component located inside the stator, responsible for converting electrical energy into mechanical motion or vice versa. Both components work together to enable efficient electromagnetic energy transfer in various electrical machines.

Fundamental Differences Between Stator and Rotor

The stator is the stationary part of an electric motor that generates a magnetic field, while the rotor is the rotating component that turns and produces mechanical output. Stators typically consist of wire windings or permanent magnets fixed around the motor housing, whereas rotors contain conductors or magnets mounted on a shaft. Understanding the fundamental differences between stator and rotor helps you optimize motor design and troubleshoot performance issues effectively.

Construction and Design Features

The stator features a stationary core made of laminated steel sheets with insulated windings embedded in slots, designed to create a stable magnetic field. The rotor, typically constructed as either a squirrel-cage or wound type, contains conductive bars or coils that rotate within the stator's field to induce motion. Understanding these distinct construction and design features is crucial for optimizing your electric motor's performance and efficiency.

Working Principle of Stator

The stator operates by generating a rotating magnetic field when electrical current passes through its windings, which remains stationary in the motor's frame. This rotating magnetic field induces a current in the rotor, causing it to turn and create mechanical motion. Understanding the working principle of the stator is essential for optimizing your motor's efficiency and performance.

Working Principle of Rotor

The rotor operates on the principle of electromagnetic induction, where a rotating magnetic field generated by the stator induces current in the rotor windings, producing torque that causes it to spin. This interaction between the stator's magnetic field and the rotor's induced current is fundamental to converting electrical energy into mechanical motion. Understanding the rotor's working principle helps optimize your motor's efficiency and performance in various industrial applications.

Types of Stators and Rotors

Stators come in various types including wound stators, permanent magnet stators, and salient pole stators, each designed to generate a magnetic field in different motor applications. Rotors are typically classified as squirrel cage rotors, wound rotors, and permanent magnet rotors, tailored to provide torque and rotational motion based on the motor's operational needs. Understanding the specific types of stators and rotors in your electric motor can enhance performance efficiency and reliability.

Material Selection for Enhanced Performance

Material selection for the stator commonly involves laminated silicon steel to reduce eddy current losses and enhance magnetic properties, while rotors often use high-strength steel alloys or copper bars for superior conductivity and mechanical durability. Advanced composite materials and specialized coatings can improve thermal management and corrosion resistance in both components, directly impacting efficiency and lifespan. Optimizing your motor's performance depends on choosing materials that balance magnetic efficiency, mechanical strength, and thermal stability for both the stator and rotor.

Applications in Electrical Machines

The stator generates a stationary magnetic field essential for the operation of AC motors and synchronous generators, providing the necessary electromagnetic force for energy conversion. The rotor, designed for rotation within the stator's magnetic field, plays a crucial role in torque production in induction motors and acts as the output shaft in generators. In electrical machines like induction motors, synchronous motors, and alternators, the stator and rotor collaborate to convert electrical energy to mechanical energy and vice versa, each optimized for their specific functions to maximize efficiency and performance.

Advantages and Limitations of Stators and Rotors

Stators offer advantages such as providing a stable magnetic field, enabling efficient energy transfer, and reducing mechanical wear due to their stationary nature, but they can be bulky and complicate cooling systems. Rotors enable rotational motion essential for torque generation and mechanical output, allowing compact design and dynamic response, though they face limitations like increased wear, need for precise balance, and susceptibility to electrical and mechanical stresses. Understanding these trade-offs is critical for optimizing motor performance in applications ranging from industrial machinery to electric vehicles.

Key Considerations for Selection and Maintenance

When selecting between a stator and rotor, consider factors like operating environment, power requirements, and cooling methods to ensure optimal performance and efficiency. Maintenance priorities differ, with stators requiring regular insulation checks and rotor upkeep focusing on balancing and bearing inspections. Your equipment's longevity depends on timely lubrication, vibration monitoring, and adherence to manufacturer guidelines for both components.

Stator vs rotor Infographic

libmatt.com

libmatt.com