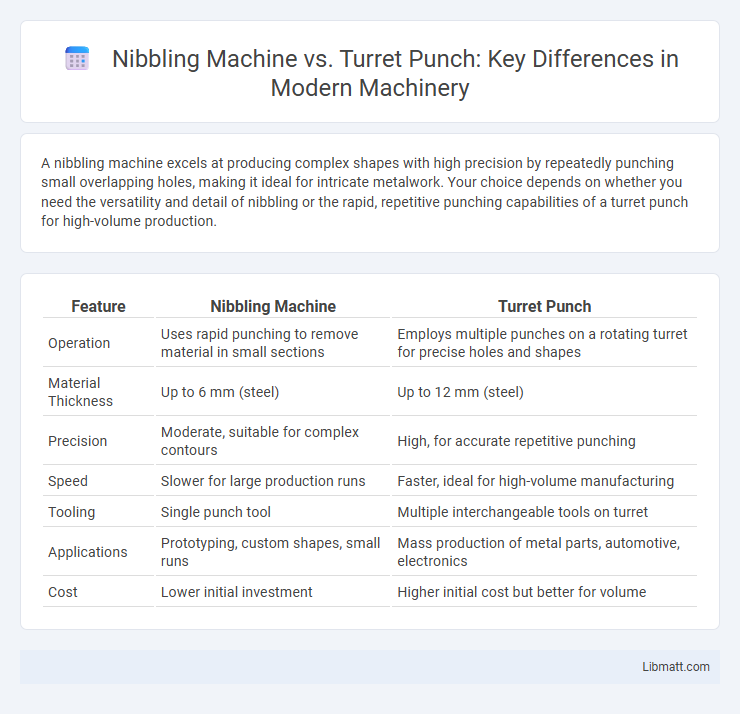

A nibbling machine excels at producing complex shapes with high precision by repeatedly punching small overlapping holes, making it ideal for intricate metalwork. Your choice depends on whether you need the versatility and detail of nibbling or the rapid, repetitive punching capabilities of a turret punch for high-volume production.

Table of Comparison

| Feature | Nibbling Machine | Turret Punch |

|---|---|---|

| Operation | Uses rapid punching to remove material in small sections | Employs multiple punches on a rotating turret for precise holes and shapes |

| Material Thickness | Up to 6 mm (steel) | Up to 12 mm (steel) |

| Precision | Moderate, suitable for complex contours | High, for accurate repetitive punching |

| Speed | Slower for large production runs | Faster, ideal for high-volume manufacturing |

| Tooling | Single punch tool | Multiple interchangeable tools on turret |

| Applications | Prototyping, custom shapes, small runs | Mass production of metal parts, automotive, electronics |

| Cost | Lower initial investment | Higher initial cost but better for volume |

Introduction to Nibbling Machines and Turret Punches

Nibbling machines utilize a series of small, rapid punches to cut intricate shapes and contours in sheet metal, providing flexibility for complex designs. Turret punches feature a rotating turret equipped with multiple punching tools, enabling efficient and precise punching of repetitive patterns in metal fabrication. Both machines play critical roles in metalworking, with nibbling machines excelling in custom, detailed cuts and turret punches optimizing speed and repeatability.

Overview of Sheet Metal Fabrication Techniques

Nibbling machines and turret punches are key technologies in sheet metal fabrication, offering distinct approaches to material cutting and shaping. Nibbling machines excel at producing intricate cuts and contours by removing small metal segments, enabling precise and customizable designs. Your choice depends on project requirements, with turret punches providing rapid, repetitive punching operations ideal for standardized hole patterns and high-volume production.

How Nibbling Machines Work: Key Features and Functions

Nibbling machines operate by repeatedly punching small, overlapping holes along a designated path to cut sheet metal with high precision and minimal distortion. Key features include a robust punch mechanism, adjustable feed rates, and the ability to create complex shapes and intricate patterns in various metal gauges. Their automated control systems enhance productivity by allowing continuous, accurate cutting without manual intervention.

Turret Punch Press: Mechanism and Capabilities

Turret punch presses operate using a rotating turret with multiple fixed punching tools that rapidly create precise holes and shapes in sheet metal by driving the selected tool through the material. These machines excel in versatility, allowing quick tool changes and high-speed production, ideal for complex patterns and repetitive tasks. Their mechanism supports a wide range of punch sizes and shapes, enabling efficient processing of diverse metal gauges and thicknesses.

Precision and Cutting Quality: A Comparative Analysis

Nibbling machines provide high precision by executing continuous, intricate cuts through overlapping punches, ideal for complex shapes and fine detailing in sheet metal. Turret punch presses excel in cutting quality with rapid, repeatable strokes and a variety of punch tools, delivering consistent hole patterns and smooth edges on thicker materials. Your choice between nibbling machines and turret punches depends on the required precision level and the specific cutting quality for your metal fabrication needs.

Production Speed and Efficiency Differences

Nibbling machines offer high precision and flexibility for complex, small-cut patterns but typically operate at slower production speeds compared to turret punches. Turret punch machines excel in rapid, repetitive hole punching and forming tasks, achieving higher throughput and efficiency for large-volume sheet metal fabrication. Choosing between the two depends on balancing the need for intricate detail versus maximizing cycle time and output capacity.

Versatility and Applications in Manufacturing

Nibbling machines offer exceptional versatility by enabling complex shapes and fine details in sheet metal fabrication, making them ideal for prototypes and small batch runs. Turret punch presses excel in high-speed, repetitive punching of standardized patterns, suitable for large-scale production in automotive and appliance industries. Choosing between the two depends on the specific manufacturing needs, with nibbling machines favored for customization and turret punches for efficiency and volume.

Material and Thickness Limitations

Nibbling machines excel in processing a wide range of materials including steel, aluminum, and copper with thicknesses typically up to 6mm, allowing for detailed and intricate cuts. Turret punch presses handle thicker materials more efficiently, often up to 16mm, with faster punching speeds suitable for high-volume production. Material type and thickness govern the choice between nibbling machines and turret punches, influencing precision, speed, and application suitability.

Cost Considerations: Initial Investment and Maintenance

Nibbling machines generally have a lower initial investment compared to turret punches, making them more accessible for small to medium-sized businesses. Maintenance costs for nibbling machines tend to be higher due to wear on the tooling, which requires frequent replacement and adjustments. Your decision should weigh the upfront affordability of nibbling machines against the potentially lower long-term maintenance expenses of turret punch systems.

Choosing the Right Machine for Your Fabrication Needs

Choosing the right machine for your fabrication needs depends on factors like material thickness, precision, and production volume. A nibbling machine excels in complex, intricate shapes on thinner materials, offering flexibility and minimal distortion, while a turret punch provides high-speed, repetitive punching ideal for thicker sheets and standard shapes. Assess your project specifications to determine whether the nibbling machine's adaptability or the turret punch's efficiency aligns better with your manufacturing goals.

Nibbling machine vs turret punch Infographic

libmatt.com

libmatt.com