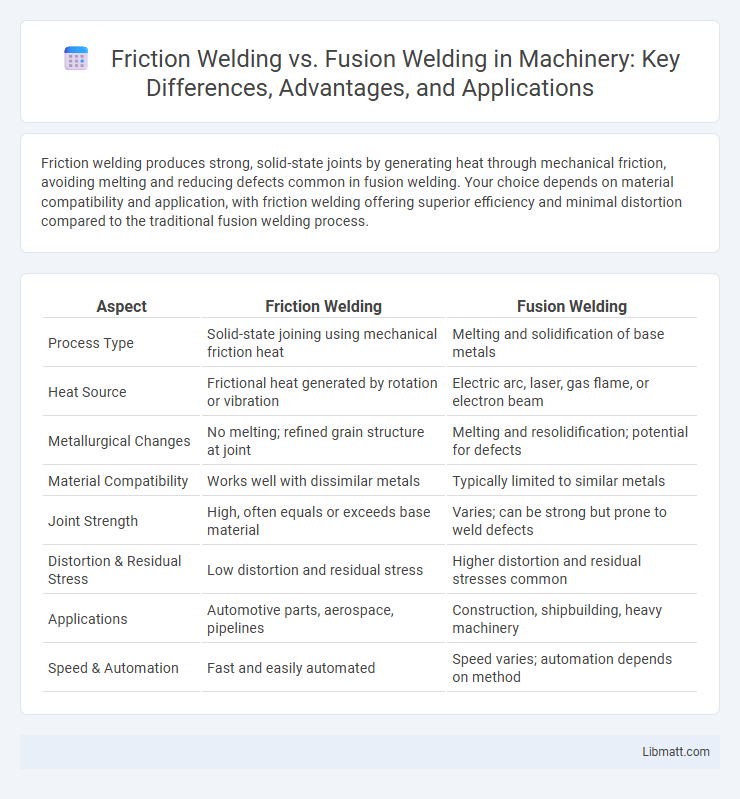

Friction welding produces strong, solid-state joints by generating heat through mechanical friction, avoiding melting and reducing defects common in fusion welding. Your choice depends on material compatibility and application, with friction welding offering superior efficiency and minimal distortion compared to the traditional fusion welding process.

Table of Comparison

| Aspect | Friction Welding | Fusion Welding |

|---|---|---|

| Process Type | Solid-state joining using mechanical friction heat | Melting and solidification of base metals |

| Heat Source | Frictional heat generated by rotation or vibration | Electric arc, laser, gas flame, or electron beam |

| Metallurgical Changes | No melting; refined grain structure at joint | Melting and resolidification; potential for defects |

| Material Compatibility | Works well with dissimilar metals | Typically limited to similar metals |

| Joint Strength | High, often equals or exceeds base material | Varies; can be strong but prone to weld defects |

| Distortion & Residual Stress | Low distortion and residual stress | Higher distortion and residual stresses common |

| Applications | Automotive parts, aerospace, pipelines | Construction, shipbuilding, heavy machinery |

| Speed & Automation | Fast and easily automated | Speed varies; automation depends on method |

Introduction to Welding Techniques

Friction welding and fusion welding are distinct techniques used to join metals, each offering unique advantages depending on the application. Friction welding generates heat through mechanical friction between workpieces, allowing for a solid-state bond without melting, which preserves material properties. Fusion welding, on the other hand, melts the base metals to create a joint, making it suitable for a wide range of materials and thicknesses, but it may introduce thermal stresses and distortions.

What is Friction Welding?

Friction welding is a solid-state joining process that generates heat through mechanical friction between two workpieces, causing them to soften and bond without melting. This technique preserves the material properties and eliminates defects commonly found in fusion welding, such as porosity or cracking. It is widely used in aerospace, automotive, and manufacturing industries for joining dissimilar metals with high strength and structural integrity.

What is Fusion Welding?

Fusion welding is a process that joins materials by melting their base metals together, creating a strong, permanent bond as they cool and solidify. You can achieve this through methods such as arc welding, gas welding, or laser welding, where heat sources directly melt the materials without applying pressure. This technique is widely used in industries requiring metal fabrication due to its ability to produce high-strength joints in various metals and alloys.

Key Differences Between Friction and Fusion Welding

Friction welding joins materials through heat generated by mechanical friction without melting the base metals, while fusion welding melts the materials to create a joint upon solidification. Key differences include temperature control, with friction welding operating below melting points and fusion welding reaching melting temperatures, resulting in distinct microstructures and mechanical properties. Friction welding offers faster process times and minimal distortion, whereas fusion welding provides flexibility in joint design but often requires filler materials and post-weld treatments.

Advantages of Friction Welding

Friction welding offers advantages such as producing high-strength, defect-free joints without melting the base materials, which reduces thermal distortion and residual stresses. The process is energy-efficient and environmentally friendly, eliminating the need for filler materials or shielding gases commonly required in fusion welding. Your projects benefit from faster production cycles and the ability to join dissimilar metals with superior mechanical properties compared to traditional fusion welding methods.

Advantages of Fusion Welding

Fusion welding offers significant advantages, including the ability to join a wide variety of metals and alloys with strong, continuous bonds. This process allows for high weld strength and excellent metallurgical properties, making it ideal for structural applications. You benefit from fusion welding's versatility and efficiency in producing durable, high-quality welds across diverse industrial sectors.

Applications of Friction Welding

Friction welding excels in joining dissimilar metals and components with complex geometries, making it ideal for aerospace, automotive, and industrial machinery applications. Your manufacturing process can benefit from its ability to produce high-strength, defect-free joints without melting the base materials, preserving their mechanical properties. This solid-state welding method also reduces distortion and improves energy efficiency compared to fusion welding techniques.

Applications of Fusion Welding

Fusion welding is extensively used in industries like aerospace, automotive, and construction due to its ability to join dissimilar metals and complex geometries with high strength and precision. This method is ideal for manufacturing pipelines, pressure vessels, and shipbuilding where airtight and strong joints are essential. Your choice of fusion welding can enhance production efficiency and structural integrity in critical applications.

Limitations and Challenges

Friction welding faces limitations such as restrictions on joining dissimilar metals with vastly different melting points and challenges in controlling heat input to avoid defects like flash or overheating. Fusion welding struggles with issues like porosity, cracking, and distortion due to melting and solidification, especially in thick or highly alloyed materials. Understanding these challenges helps you select the appropriate welding method for your specific applications, balancing strength, efficiency, and material compatibility.

Choosing the Right Welding Method

Friction welding offers a solid-state process ideal for joining dissimilar metals with minimal distortion, making it suitable for aerospace and automotive industries requiring high strength and precision. Fusion welding, involving melting and solidification, excels in applications demanding complex joint geometries and thicker materials, commonly used in construction and shipbuilding. Selecting the right welding method depends on factors such as material compatibility, required mechanical properties, production speed, and cost efficiency.

Friction welding vs fusion welding Infographic

libmatt.com

libmatt.com