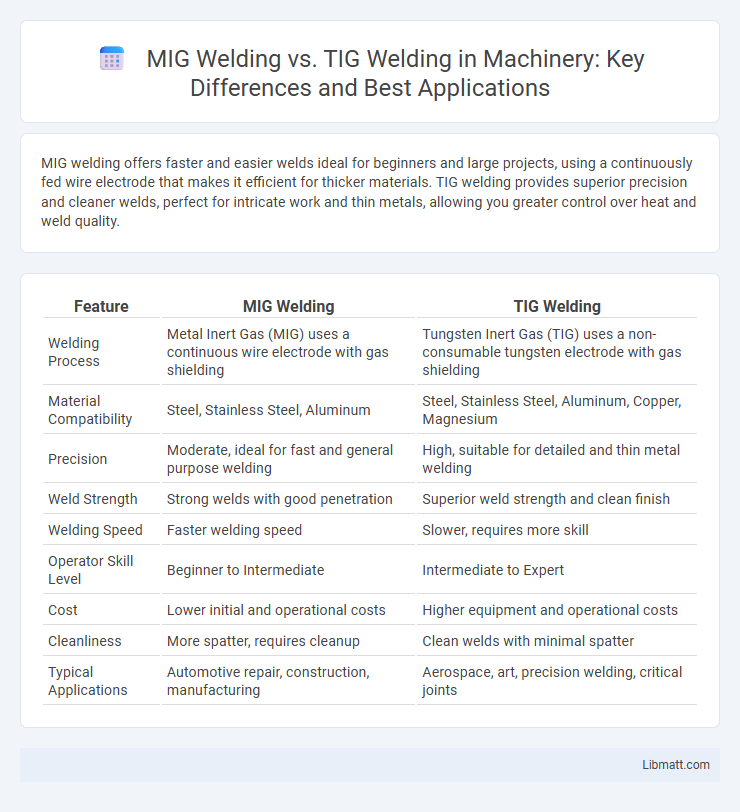

MIG welding offers faster and easier welds ideal for beginners and large projects, using a continuously fed wire electrode that makes it efficient for thicker materials. TIG welding provides superior precision and cleaner welds, perfect for intricate work and thin metals, allowing you greater control over heat and weld quality.

Table of Comparison

| Feature | MIG Welding | TIG Welding |

|---|---|---|

| Welding Process | Metal Inert Gas (MIG) uses a continuous wire electrode with gas shielding | Tungsten Inert Gas (TIG) uses a non-consumable tungsten electrode with gas shielding |

| Material Compatibility | Steel, Stainless Steel, Aluminum | Steel, Stainless Steel, Aluminum, Copper, Magnesium |

| Precision | Moderate, ideal for fast and general purpose welding | High, suitable for detailed and thin metal welding |

| Weld Strength | Strong welds with good penetration | Superior weld strength and clean finish |

| Welding Speed | Faster welding speed | Slower, requires more skill |

| Operator Skill Level | Beginner to Intermediate | Intermediate to Expert |

| Cost | Lower initial and operational costs | Higher equipment and operational costs |

| Cleanliness | More spatter, requires cleanup | Clean welds with minimal spatter |

| Typical Applications | Automotive repair, construction, manufacturing | Aerospace, art, precision welding, critical joints |

Introduction to MIG and TIG Welding

MIG welding uses a continuous wire electrode fed through a welding gun, making it ideal for fast, high-production applications on various metals like steel and aluminum. TIG welding employs a non-consumable tungsten electrode to produce precise, clean welds, suited for thin materials and detailed work on stainless steel and other metals. Understanding the fundamental differences in technique and application helps you select the right welding process for your project's requirements.

Basic Principles of MIG Welding

MIG welding, or Metal Inert Gas welding, uses a continuous solid wire electrode fed through a welding gun while an inert gas, typically argon or a mix of argon and carbon dioxide, shields the weld pool from contamination. The process operates on the principle of an electric arc formed between the wire electrode and the base metal, melting both to create a strong, clean weld. MIG welding is widely recognized for its speed and ease of use, making it ideal for welding thin to medium-thickness metals such as steel, aluminum, and stainless steel.

Basic Principles of TIG Welding

TIG welding, or Tungsten Inert Gas welding, uses a non-consumable tungsten electrode to produce the weld, while an inert gas such as argon shields the weld area from contamination. This process allows for greater control and precision, making it ideal for welding thin metals and non-ferrous materials like aluminum and magnesium. Unlike MIG welding, TIG welding does not use a wire feed but requires a separate filler material, resulting in clean, high-quality welds with minimal spatter.

Equipment and Setup Differences

MIG welding equipment includes a wire feeder, welding gun, and a shielding gas supply, making setup relatively simple and faster for beginners or high-production environments. TIG welding requires a more complex setup with a torch that uses a non-consumable tungsten electrode and a separate filler rod, along with precise gas control, typically argon, for superior weld quality. The difference in equipment complexity directly affects the preparation time, skill level needed, and the applications best suited for each welding process.

Materials Compatible with MIG and TIG Welding

MIG welding effectively joins a wide range of materials including mild steel, stainless steel, and aluminum, making it versatile for automotive and fabrication industries. TIG welding excels in precision applications, compatible with materials such as stainless steel, aluminum, magnesium, and copper alloys, providing superior control for thin sections and critical welds. Each welding method's material compatibility influences its ideal use based on project requirements for strength, finish, and material thickness.

Welding Speed and Efficiency Comparison

MIG welding offers significantly faster welding speeds due to continuous wire feed, making it ideal for high-production environments and large-scale fabrication. TIG welding, while slower, provides greater precision and control, resulting in higher-quality welds for intricate or thin materials. Efficiency in MIG welding is generally higher for thick materials and long welds, whereas TIG excels in applications requiring fine detail and superior weld aesthetics.

Weld Quality and Finish

MIG welding typically produces faster welds with moderate spatter and a somewhat rougher finish, making it suitable for thicker materials and industrial applications. TIG welding delivers superior weld quality with precise control, resulting in clean, aesthetically pleasing, and smooth finishes ideal for thin metals and stainless steel projects. The high arc stability and lower heat input in TIG welding minimize distortion and ensure stronger, more refined welds compared to the broader, more rugged weld beads characteristic of MIG welding.

Skill Level and Learning Curve

MIG welding requires a lower skill level and has a shorter learning curve, making it ideal for beginners and quick project completion. TIG welding demands higher precision and control, resulting in a steeper learning curve but offering superior weld quality and aesthetics. Professionals often choose TIG for detailed work despite the increased skill requirement, while MIG suits faster, less complex applications.

Cost Considerations

MIG welding generally offers lower initial equipment costs and faster welding speeds, making it more economical for large-scale production and thicker materials. TIG welding requires more expensive machinery and skilled labor, increasing overall expenses but providing superior precision and quality for thin or complex metalwork. Cost-effectiveness depends on project requirements, with MIG favored for budget-conscious tasks and TIG preferred when weld quality and detail are critical.

Choosing the Right Welding Method

MIG welding offers faster operation and easier learning curves, making it ideal for thicker metals and high-production environments. TIG welding provides superior precision and cleaner welds, better suited for thin materials and intricate projects requiring high-quality finishes. Selecting the right welding method depends on material type, project complexity, and desired weld appearance for optimal results.

MIG welding vs TIG welding Infographic

libmatt.com

libmatt.com