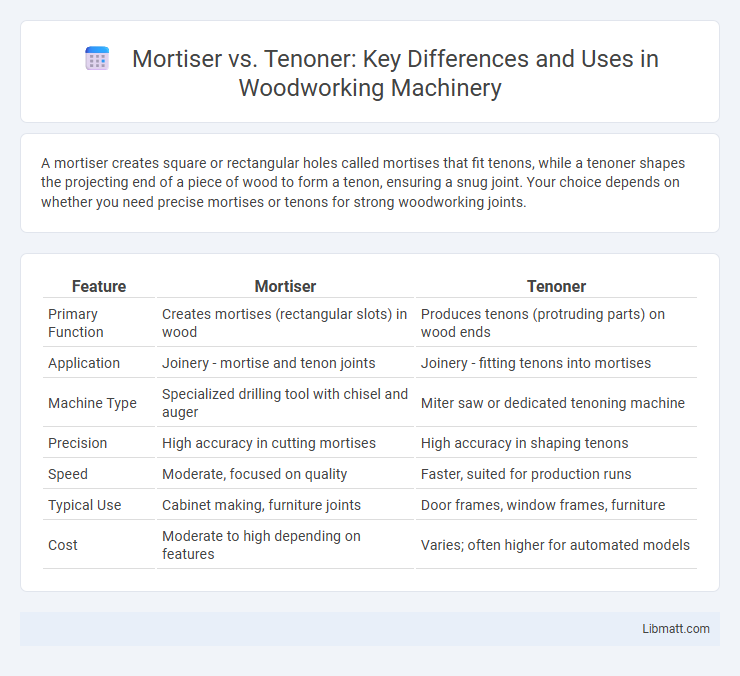

A mortiser creates square or rectangular holes called mortises that fit tenons, while a tenoner shapes the projecting end of a piece of wood to form a tenon, ensuring a snug joint. Your choice depends on whether you need precise mortises or tenons for strong woodworking joints.

Table of Comparison

| Feature | Mortiser | Tenoner |

|---|---|---|

| Primary Function | Creates mortises (rectangular slots) in wood | Produces tenons (protruding parts) on wood ends |

| Application | Joinery - mortise and tenon joints | Joinery - fitting tenons into mortises |

| Machine Type | Specialized drilling tool with chisel and auger | Miter saw or dedicated tenoning machine |

| Precision | High accuracy in cutting mortises | High accuracy in shaping tenons |

| Speed | Moderate, focused on quality | Faster, suited for production runs |

| Typical Use | Cabinet making, furniture joints | Door frames, window frames, furniture |

| Cost | Moderate to high depending on features | Varies; often higher for automated models |

Introduction to Mortisers and Tenoners

Mortisers are specialized woodworking machines designed to cut precise square or rectangular holes for mortise joints, essential in frame and panel construction. Tenoners, on the other hand, are used to produce tenons, the projecting parts that fit into mortises to form strong, interlocking joints. Both tools are critical in joinery, enabling efficient production of durable and accurate wood connections.

What is a Mortiser?

A mortiser is a specialized woodworking tool designed to cut precise rectangular or square holes, known as mortises, into wood to create strong, interlocking joints called mortise and tenon. This tool enhances accuracy and efficiency in joinery tasks compared to manual chiseling, especially in repetitive or large-scale projects. Your woodworking projects benefit from the clean, consistent cuts a mortiser delivers, ensuring tight-fitting joints and durable construction.

What is a Tenoner?

A tenoner is a specialized woodworking machine designed to cut precise tenons, which are projecting pieces of wood used to join two parts together. It operates by shaping the end of a workpiece to fit perfectly into a corresponding mortise, ensuring strong and accurate joinery. Tenoners are essential for producing high-quality, repeatable joints in furniture and cabinetry manufacturing.

Key Differences Between Mortisers and Tenoners

Mortisers are specialized woodworking machines designed primarily for cutting square or rectangular holes (mortises) in wood, facilitating the creation of mortise and tenon joints, while tenoners focus on precisely shaping the tenon end of the joint to fit into the mortise. Mortisers typically use a chisel and drill system for hollowing out wood sections, whereas tenoners employ saws, routers, or spindle molder cutters to form accurate tenon shoulders and cheeks. The key differences lie in their operational functions, tool configurations, and their roles within the mortise and tenon joinery process, with mortisers preparing the receiving cavity and tenoners crafting the projecting tongue.

Mortiser: Types and Functions

Mortisers come in various types, including hollow chisel mortisers, chain mortisers, and horizontal mortisers, each designed for specific woodworking tasks. Hollow chisel mortisers excel at cutting square or rectangular mortises by combining a drill bit and chisel, while chain mortisers use a chain to carve deep mortises in heavy timber. Your choice of mortiser should align with the function needed, whether precision joinery or large-scale timber framing.

Tenoner: Types and Uses

Tenoners come in various types, including horizontal, vertical, and chain tenoners, each designed to create precise tenons for different joinery needs. Horizontal tenoners are ideal for trimming tenons on small to medium-sized workpieces, while vertical tenoners excel in producing long or large tenons with high accuracy. Chain tenoners are suited for high-volume production, offering speed and repeatability in crafting mortise and tenon joints for furniture and cabinetry.

Pros and Cons of Mortisers

Mortisers offer precise and clean cuts ideal for creating strong, square mortises, enhancing joint stability in woodworking projects. They greatly increase efficiency, especially for repetitive tasks, saving time compared to manual chiseling. However, mortisers tend to be more expensive and bulky, requiring space in a workshop and regular maintenance to ensure accuracy.

Pros and Cons of Tenoners

Tenoners offer precise and consistent cuts, making them ideal for producing strong, high-quality joints in woodworking projects. Their efficiency and accuracy can significantly reduce labor time, but they often come with a higher initial cost and require more maintenance compared to mortisers. Your choice depends on the scale and complexity of your projects, as tenoners excel in professional settings demanding repeatable, precise tenons.

Choosing the Right Machine for Your Woodworking Project

Selecting between a mortiser and a tenoner depends on the specific joinery requirements of your woodworking project. A mortiser is ideal for cutting precise rectangular or square holes (mortises) into wood, perfect for creating strong mortise-and-tenon joints, while a tenoner is designed to shape the tenon on the end of a wooden piece for a snug fit into the mortise. Evaluate factors like project scale, joint accuracy, and available workspace to choose the machine that ensures durability and efficiency in your craft.

Conclusion: Mortiser vs Tenoner – Which Should You Choose?

Choosing between a mortiser and a tenoner depends on your woodworking needs and project scope; a mortiser excels at creating precise square holes for strong mortise-and-tenon joints, while a tenoner is ideal for producing tenons quickly and accurately. Your decision should consider factors like the volume of work, desired joint quality, and available equipment space. For professional-grade joinery demanding high precision, combining both tools often delivers the best results.

Mortiser vs tenoner Infographic

libmatt.com

libmatt.com