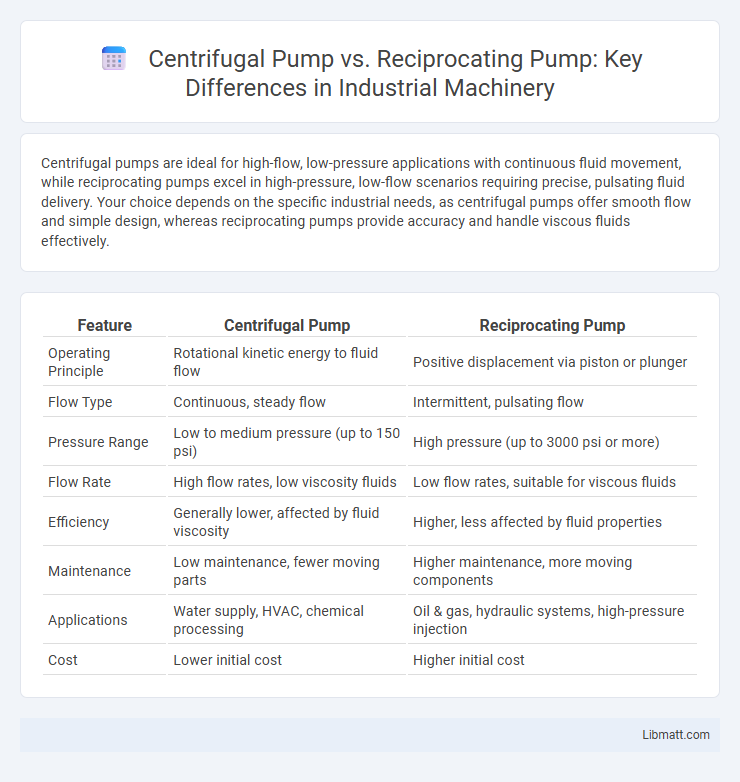

Centrifugal pumps are ideal for high-flow, low-pressure applications with continuous fluid movement, while reciprocating pumps excel in high-pressure, low-flow scenarios requiring precise, pulsating fluid delivery. Your choice depends on the specific industrial needs, as centrifugal pumps offer smooth flow and simple design, whereas reciprocating pumps provide accuracy and handle viscous fluids effectively.

Table of Comparison

| Feature | Centrifugal Pump | Reciprocating Pump |

|---|---|---|

| Operating Principle | Rotational kinetic energy to fluid flow | Positive displacement via piston or plunger |

| Flow Type | Continuous, steady flow | Intermittent, pulsating flow |

| Pressure Range | Low to medium pressure (up to 150 psi) | High pressure (up to 3000 psi or more) |

| Flow Rate | High flow rates, low viscosity fluids | Low flow rates, suitable for viscous fluids |

| Efficiency | Generally lower, affected by fluid viscosity | Higher, less affected by fluid properties |

| Maintenance | Low maintenance, fewer moving parts | Higher maintenance, more moving components |

| Applications | Water supply, HVAC, chemical processing | Oil & gas, hydraulic systems, high-pressure injection |

| Cost | Lower initial cost | Higher initial cost |

Introduction to Centrifugal and Reciprocating Pumps

Centrifugal pumps use a rotating impeller to convert kinetic energy into fluid flow, making them ideal for high flow rate applications with low viscosity liquids. Reciprocating pumps operate with a piston or diaphragm, providing high pressure output suitable for precise, low flow rate tasks involving viscous or shear-sensitive fluids. Choosing the right pump depends on your specific requirements for flow rate, pressure, and fluid characteristics.

Working Principle: Centrifugal vs Reciprocating Pump

Centrifugal pumps operate by converting rotational kinetic energy from an impeller into hydrodynamic energy to move fluid, relying on continuous flow and velocity increase. Reciprocating pumps use a piston or plunger mechanism to create positive displacement, generating pressure by trapping fluid and mechanically forcing it through the discharge pipe in discrete strokes. The centrifugal pump excels in high flow, low-pressure applications, while reciprocating pumps are preferred for high pressure, low flow scenarios requiring precise displacement.

Key Components Comparison

Centrifugal pumps consist of key components including an impeller, casing, and a shaft, where the impeller accelerates fluid to create flow. Reciprocating pumps feature components such as a piston, cylinder, suction and discharge valves, which work together to create positive displacement by moving fluid in and out of the cylinder. The centrifugal pump's continuous rotary motion contrasts with the reciprocating pump's back-and-forth motion, influencing their design complexity and maintenance requirements.

Efficiency and Performance Differences

Centrifugal pumps offer high flow rates and are most efficient under steady, low-viscosity fluid conditions, making them ideal for continuous pumping applications. Reciprocating pumps maintain efficiency at high pressures and provide precise flow control, excelling in applications requiring accurate metering and handling viscous fluids. The efficiency of centrifugal pumps typically declines at low flow rates, whereas reciprocating pumps maintain consistent performance across varying pressures.

Applications: Where Each Pump Excels

Centrifugal pumps excel in applications requiring high flow rates and low to moderate pressure, such as water supply, irrigation, and chemical processing where continuous operation is essential. Reciprocating pumps are ideal for high-pressure, low-flow applications like oil and gas extraction, hydraulic systems, and precise dosing where accurate flow control is critical. Choosing between the two depends on the required pressure, flow rate, and the nature of the fluid being handled.

Maintenance and Operational Considerations

Centrifugal pumps generally require less maintenance due to fewer moving parts and simpler design, reducing downtime and operational costs in continuous flow applications. Reciprocating pumps demand frequent inspection and maintenance because of their complex valve mechanisms and pistons, which can wear out faster under high-pressure conditions. Your choice should consider the operational environment and maintenance capabilities, as centrifugal pumps excel in low-viscosity fluids and high flow rates, while reciprocating pumps are better suited for precise dosing and handling viscous or slurry fluids.

Cost Analysis: Initial and Lifetime Expenses

Centrifugal pumps generally have lower initial costs and simpler designs, making them more cost-effective for high-flow, low-pressure applications. Reciprocating pumps, though expensive upfront due to complex construction and precision components, often provide higher efficiency and durability leading to lower lifetime operating expenses in low-flow, high-pressure settings. Maintenance and energy consumption play critical roles in total cost of ownership, with centrifugal pumps requiring less frequent service but potentially higher energy costs over time compared to reciprocating pumps.

Advantages of Centrifugal Pumps

Centrifugal pumps offer high flow rates and are ideal for handling large volumes of low-viscosity fluids with continuous, smooth flow, making them suitable for water supply, irrigation, and chemical processing industries. These pumps have simpler designs with fewer moving parts, resulting in lower maintenance costs and higher reliability compared to reciprocating pumps. Their ability to operate efficiently at varying speeds and pressures provides flexibility and energy savings in applications requiring steady fluid movement.

Advantages of Reciprocating Pumps

Reciprocating pumps offer high-pressure delivery with precise flow control, making them ideal for applications requiring accurate dosing or high-pressure output. Their positive displacement mechanism ensures consistent performance even at low flow rates, unlike centrifugal pumps that depend on velocity. You benefit from their ability to handle viscous fluids and maintain efficiency in conditions where variable flow and pressure are necessary.

Choosing the Right Pump for Your Needs

Selecting the right pump depends on the application requirements: centrifugal pumps excel in high flow rate and low pressure scenarios, making them ideal for water supply and HVAC systems. Reciprocating pumps deliver high pressure at low flow rates, suitable for precise dosing and hydraulic applications. Understanding flow rate, pressure needs, and fluid characteristics ensures optimal pump performance and energy efficiency.

Centrifugal pump vs reciprocating pump Infographic

libmatt.com

libmatt.com