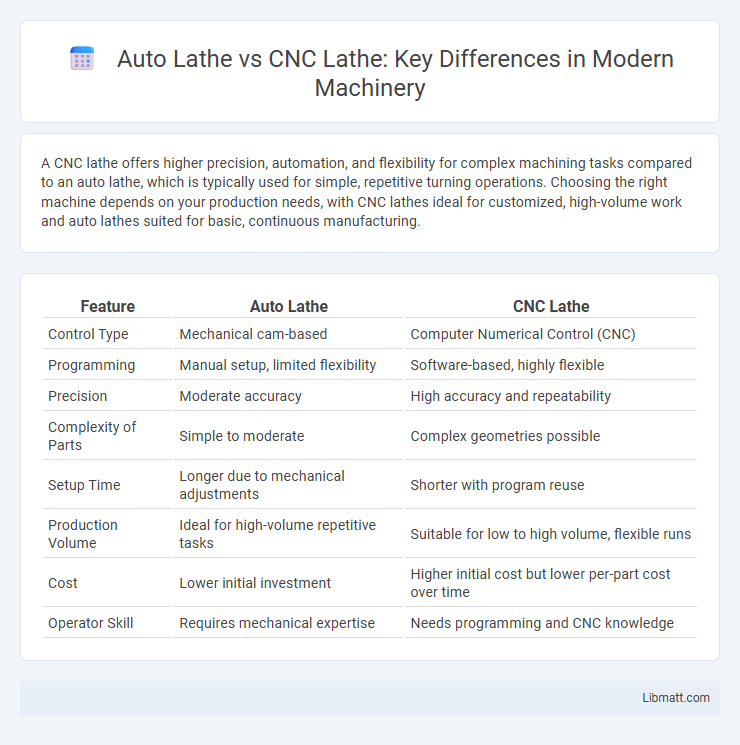

A CNC lathe offers higher precision, automation, and flexibility for complex machining tasks compared to an auto lathe, which is typically used for simple, repetitive turning operations. Choosing the right machine depends on your production needs, with CNC lathes ideal for customized, high-volume work and auto lathes suited for basic, continuous manufacturing.

Table of Comparison

| Feature | Auto Lathe | CNC Lathe |

|---|---|---|

| Control Type | Mechanical cam-based | Computer Numerical Control (CNC) |

| Programming | Manual setup, limited flexibility | Software-based, highly flexible |

| Precision | Moderate accuracy | High accuracy and repeatability |

| Complexity of Parts | Simple to moderate | Complex geometries possible |

| Setup Time | Longer due to mechanical adjustments | Shorter with program reuse |

| Production Volume | Ideal for high-volume repetitive tasks | Suitable for low to high volume, flexible runs |

| Cost | Lower initial investment | Higher initial cost but lower per-part cost over time |

| Operator Skill | Requires mechanical expertise | Needs programming and CNC knowledge |

Introduction to Auto Lathe and CNC Lathe

Auto lathes, also known as automatic lathes, are specialized machines designed for high-volume production of small, precise parts typically using cam-driven operations. CNC lathes utilize computer numerical control to deliver greater flexibility, accuracy, and automation in machining complex geometries with programmable tool paths. Both machines excel in metal turning processes, but CNC lathes offer enhanced programmability and adaptability compared to traditional auto lathes.

Definition of Auto Lathe

An auto lathe is a specialized, automated lathe machine designed primarily for high-volume production of small, precision parts, often using cam-driven mechanisms to control tool movements. Unlike CNC lathes, which utilize computer numerical control for flexibility and complex shaping, auto lathes operate with preset mechanical cams for repetitive machining tasks. This results in faster cycle times for simple geometries, ideal for manufacturing components like screws, pins, and fasteners.

Definition of CNC Lathe

CNC lathe is a computer-controlled machine tool designed for precise and automated turning operations on cylindrical workpieces. Unlike traditional auto lathes, CNC lathes offer enhanced versatility, complex tool movements, and programmability for high-accuracy manufacturing. Your manufacturing process can benefit from CNC lathe technology due to its ability to produce consistent and intricate parts with minimal human intervention.

Key Differences Between Auto Lathe and CNC Lathe

Auto lathes operate using mechanical cams and manual controls, ideal for high-volume production of small, simple parts, while CNC lathes utilize computer numerical control for programmable precision and versatility in complex machining tasks. CNC lathes offer superior flexibility, allowing you to easily switch between different programs and part designs, whereas auto lathes require physical reconfiguration for each job change. The key distinctions lie in automation level, precision, adaptability, and setup time, with CNC lathes excelling in complex, customizable manufacturing environments.

Precision and Accuracy Comparison

Auto lathes offer high precision for simple, repetitive tasks due to their automated cam-driven mechanisms, but CNC lathes excel in precision and accuracy for complex geometries through computer-controlled programming. CNC lathes achieve tighter tolerances, often within +-0.001 mm, making them ideal for advanced manufacturing requiring complex shapes or multi-axis machining. The digital control in CNC systems minimizes human error and ensures consistent accuracy across large production runs compared to the mechanical limitations of auto lathes.

Production Speed and Efficiency

Auto lathes typically offer high production speed for small, simple parts due to their specialized, repetitive operations. CNC lathes provide greater efficiency and versatility, enabling complex, precise machining with faster setup changes and automation integration. Your choice depends on whether maximum output for uniform parts or flexible, high-precision machining best suits your production needs.

Ease of Operation and Automation Level

Auto lathes offer simpler operation with mechanical cams or basic automation, ideal for high-volume, repetitive turning tasks requiring minimal programming. CNC lathes provide advanced ease of operation through computer control, enabling complex geometries, precise adjustments, and integration with CAD/CAM software for versatile production. Automation in CNC lathes is significantly higher, featuring programmable tool changes, real-time monitoring, and adaptive control systems for optimized efficiency and reduced manual intervention.

Suitable Applications for Auto and CNC Lathes

Auto lathes excel in high-volume production runs of small, intricate parts such as pins, screws, and bushings due to their ability to perform multiple operations in a single setup with minimal operator intervention. CNC lathes are suitable for complex, low to medium-volume manufacturing that requires precision and flexibility, including prototyping, custom parts, and components with intricate geometries. Your choice between auto and CNC lathes depends on production volume, part complexity, and the need for customization or automation efficiency.

Cost Analysis: Investment and Maintenance

Auto lathes typically have lower initial investment costs compared to CNC lathes but may incur higher maintenance expenses due to mechanical wear and limited automation. CNC lathes demand a higher upfront investment for advanced technology and software but benefit from reduced maintenance costs and increased precision, leading to potential savings in the long run. Your choice depends on balancing budget constraints against the need for automation efficiency and long-term operational savings.

Choosing the Right Lathe for Your Needs

Auto lathes excel in high-volume production with consistent, repetitive turning for small, simple parts, making them ideal for manufacturing environments prioritizing speed and efficiency. CNC lathes offer greater flexibility and precision, capable of handling complex designs and varied materials through programmable controls, suited for custom or low-volume jobs requiring intricate details. Selecting the right lathe depends on factors such as production volume, part complexity, material type, and desired accuracy to optimize manufacturing performance and cost-effectiveness.

Auto lathe vs CNC lathe Infographic

libmatt.com

libmatt.com