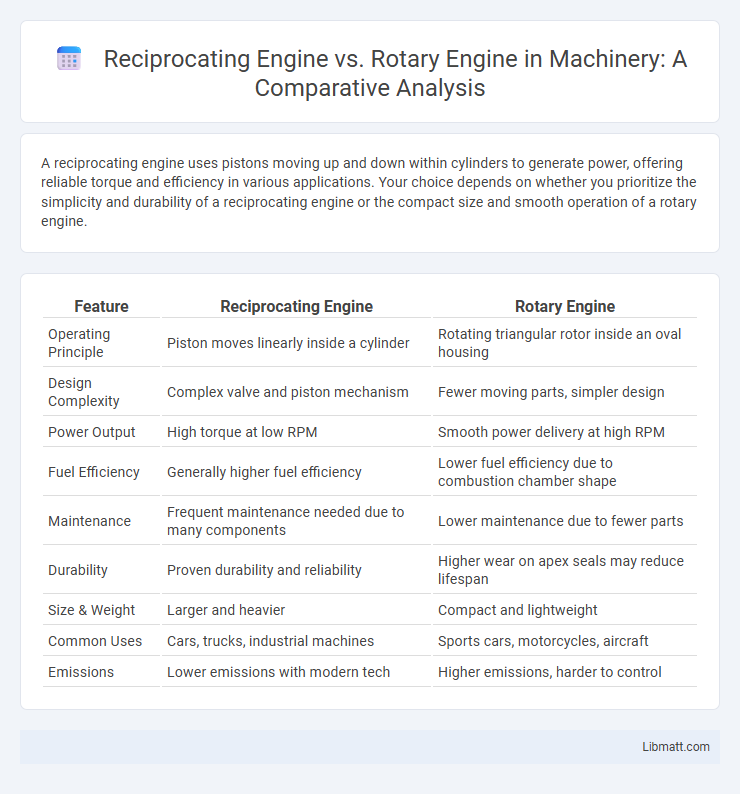

A reciprocating engine uses pistons moving up and down within cylinders to generate power, offering reliable torque and efficiency in various applications. Your choice depends on whether you prioritize the simplicity and durability of a reciprocating engine or the compact size and smooth operation of a rotary engine.

Table of Comparison

| Feature | Reciprocating Engine | Rotary Engine |

|---|---|---|

| Operating Principle | Piston moves linearly inside a cylinder | Rotating triangular rotor inside an oval housing |

| Design Complexity | Complex valve and piston mechanism | Fewer moving parts, simpler design |

| Power Output | High torque at low RPM | Smooth power delivery at high RPM |

| Fuel Efficiency | Generally higher fuel efficiency | Lower fuel efficiency due to combustion chamber shape |

| Maintenance | Frequent maintenance needed due to many components | Lower maintenance due to fewer parts |

| Durability | Proven durability and reliability | Higher wear on apex seals may reduce lifespan |

| Size & Weight | Larger and heavier | Compact and lightweight |

| Common Uses | Cars, trucks, industrial machines | Sports cars, motorcycles, aircraft |

| Emissions | Lower emissions with modern tech | Higher emissions, harder to control |

Introduction to Reciprocating and Rotary Engines

Reciprocating engines operate through the linear motion of pistons that move up and down within cylinders, converting pressure into rotational motion via a crankshaft. Rotary engines, such as the Wankel engine, utilize a triangular rotor that spins inside an epitrochoidal chamber, creating continuous rotational motion without the reciprocating components found in traditional engines. The fundamental difference lies in the mechanism of converting combustion energy into mechanical work, with reciprocating engines relying on piston cycles and rotary engines employing a rotating rotor design.

Fundamental Design Differences

Reciprocating engines use pistons moving up and down inside cylinders to convert fuel combustion into mechanical energy, featuring a complex arrangement of valves, crankshafts, and connecting rods. Rotary engines, such as the Wankel engine, rely on a triangular rotor that spins inside an epitrochoid-shaped housing, simplifying the design by reducing moving parts and eliminating valves. Your choice between these engines depends on priorities like mechanical simplicity, weight, and smoothness of power delivery.

How Reciprocating Engines Work

Reciprocating engines operate by converting the linear motion of pistons, driven by the combustion of fuel-air mixture, into rotational motion through a crankshaft. Each cylinder undergoes four distinct strokes: intake, compression, power, and exhaust, enabling efficient energy generation with controlled timing. This piston-driven mechanism provides reliable power suited for various automotive and industrial applications.

How Rotary Engines Operate

Rotary engines operate by using a triangular rotor that spins inside an epitrochoidal-shaped housing, creating combustion chambers that expand and contract to generate power. Unlike reciprocating engines with pistons moving up and down, the smooth rotational motion of the rotor provides fewer moving parts and reduced vibration. You benefit from a lightweight design and higher RPM capabilities, making rotary engines efficient for applications requiring compactness and high-speed performance.

Performance Comparison: Power and Efficiency

Reciprocating engines typically offer higher torque at lower RPMs, making them more efficient for applications requiring sustained power output, whereas rotary engines excel at delivering high RPM power with smoother operation and a higher power-to-weight ratio. The efficiency of reciprocating engines is generally better due to their advanced thermal management and fuel combustion processes, while rotary engines often experience higher fuel consumption and emissions because of their unique design. Your choice between these engines should consider the trade-off between the rotary engine's compact size and high power density against the reciprocating engine's superior fuel economy and durability.

Reliability and Maintenance Considerations

Reciprocating engines are known for their high reliability due to standardized parts and well-established maintenance practices, making spare parts readily available and repairs straightforward. Rotary engines, such as Wankel engines, have fewer moving parts which can reduce mechanical failure points but tend to experience faster wear in seals, requiring more frequent and specialized maintenance. Maintenance costs for reciprocating engines are typically lower over time, while rotary engines demand careful monitoring to prevent power loss and ensure durability.

Fuel Economy and Emissions

Reciprocating engines typically offer better fuel economy due to their higher thermal efficiency and more precise fuel combustion control compared to rotary engines. Rotary engines, while compact and lightweight, generally produce higher emissions because of incomplete combustion and oil consumption inherent in their design. You can expect lower fuel consumption and reduced pollutant output with a reciprocating engine, making it more environmentally friendly for daily driving.

Typical Applications in Vehicles and Machinery

Reciprocating engines power most cars, trucks, and motorcycles, known for their efficiency and ease of maintenance in vehicles requiring variable speeds and torque. Rotary engines excel in high-performance sports cars and drones due to their compact size and high power-to-weight ratio, making them ideal for specialized machinery needing smooth, high-rev operation. Your choice depends on the vehicle or machine's performance requirements, size constraints, and maintenance capabilities.

Pros and Cons of Each Engine Type

Reciprocating engines offer high torque at low RPM, making them efficient for heavy-duty applications, but they tend to be heavier and produce more vibrations compared to rotary engines. Rotary engines boast a compact design and smooth operation with fewer moving parts, yet they often face challenges with fuel efficiency and emissions. Your choice depends on whether you prioritize durability and torque or compactness and smooth performance.

Future Trends and Innovations in Engine Technology

Future trends in engine technology emphasize the shift towards electrification and hybrid systems, integrating reciprocating engines with advanced energy management for improved efficiency and reduced emissions. Rotary engines are being revisited through innovative materials and novel designs to enhance durability and fuel economy while maintaining their compact size and smooth operation. Your decision between these engine types may hinge on emerging developments like solid-state fuels and variable compression technologies driving next-generation performance advancements.

Reciprocating engine vs rotary engine Infographic

libmatt.com

libmatt.com