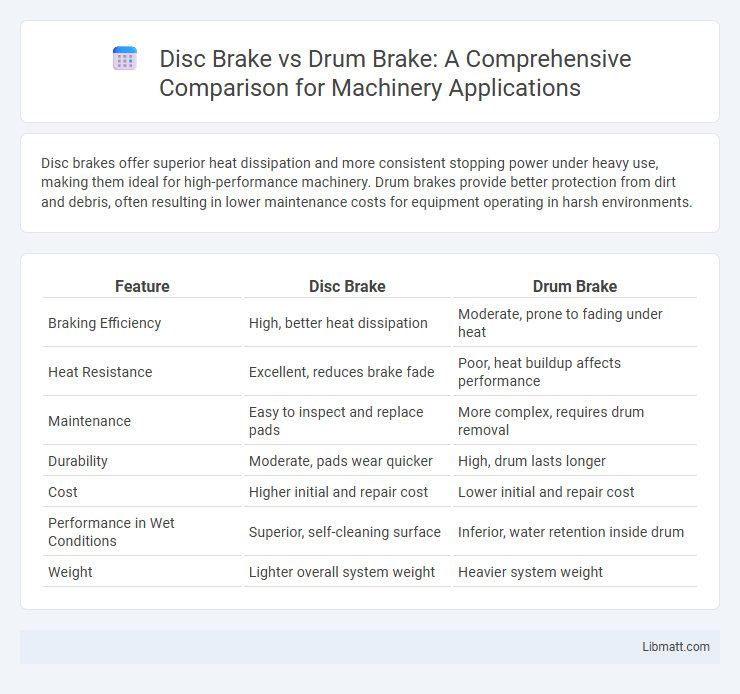

Disc brakes offer superior heat dissipation and more consistent stopping power under heavy use, making them ideal for high-performance machinery. Drum brakes provide better protection from dirt and debris, often resulting in lower maintenance costs for equipment operating in harsh environments.

Table of Comparison

| Feature | Disc Brake | Drum Brake |

|---|---|---|

| Braking Efficiency | High, better heat dissipation | Moderate, prone to fading under heat |

| Heat Resistance | Excellent, reduces brake fade | Poor, heat buildup affects performance |

| Maintenance | Easy to inspect and replace pads | More complex, requires drum removal |

| Durability | Moderate, pads wear quicker | High, drum lasts longer |

| Cost | Higher initial and repair cost | Lower initial and repair cost |

| Performance in Wet Conditions | Superior, self-cleaning surface | Inferior, water retention inside drum |

| Weight | Lighter overall system weight | Heavier system weight |

Introduction to Disc and Drum Brakes in Machinery

Disc brakes in machinery use a rotor attached to the wheel and calipers to squeeze brake pads, providing efficient heat dissipation and consistent stopping power. Drum brakes consist of brake shoes inside a drum that expand outward to create friction, commonly used in heavy-duty or cost-sensitive equipment due to their durability. Understanding your machinery's operational demands helps determine whether the superior performance of disc brakes or the robustness of drum brakes best suits your braking needs.

Fundamental Working Principles

Disc brakes operate by pressing brake pads against a rotating metal disc to create friction and slow machinery, offering efficient heat dissipation and consistent stopping power. Drum brakes function by expanding brake shoes inside a drum to generate friction and decelerate equipment, but they typically suffer from heat buildup and reduced performance under heavy use. Understanding these fundamental principles helps you choose the optimal braking system tailored to your machinery's operational demands.

Key Structural Differences

Disc brakes feature a rotor and caliper system where brake pads clamp around a spinning disc, providing efficient heat dissipation and consistent stopping power under heavy loads. Drum brakes use a drum that rotates with the wheel and brake shoes that press outward, often resulting in more complex maintenance and less effective heat management. Your choice depends on machinery requirements for performance, durability, and maintenance ease, with disc brakes typically offering superior structural advantages in industrial applications.

Performance and Stopping Power

Disc brakes offer superior performance and stopping power compared to drum brakes due to their efficient heat dissipation and consistent friction application. Your machinery benefits from disc brakes' ability to maintain braking effectiveness under heavy loads and high-speed conditions. Drum brakes may suffer from fade during prolonged use, reducing their reliability in demanding industrial environments.

Durability and Maintenance Requirements

Disc brakes offer superior durability and lower maintenance requirements compared to drum brakes, as their open design dissipates heat more effectively, reducing wear and overheating risks. Drum brakes often require frequent adjustments and replacement of internal components like shoes due to their enclosed construction, which traps heat and promotes faster degradation. Your choice should consider the operational environment and maintenance capabilities, with disc brakes typically providing longer service life and easier inspection.

Heat Dissipation and Fade Resistance

Disc brakes offer superior heat dissipation compared to drum brakes due to their exposed rotor design, which allows air to flow freely and cool the braking surface during operation. This improved heat management results in better fade resistance, ensuring consistent braking performance under heavy or repeated use in machinery applications. Your machinery will benefit from enhanced safety and reliability with disc brakes, especially in demanding environments where overheating is a concern.

Cost Comparison and Economic Considerations

Disc brakes generally have a higher upfront cost compared to drum brakes due to more complex materials and manufacturing processes, but they offer longer service intervals and better heat dissipation, reducing maintenance expenses over time. Drum brakes cost less initially but may require more frequent adjustments and part replacements, increasing long-term operational costs for your machinery. Evaluating total lifecycle expenses is crucial when choosing between disc and drum brakes to optimize your budget and equipment reliability.

Applications in Industrial Machinery

Disc brakes provide superior heat dissipation and consistent stopping power, making them ideal for high-performance industrial machinery such as CNC machines and heavy-duty presses. Drum brakes, known for their durability and cost-effectiveness, are commonly employed in slower-speed equipment like conveyor systems and packaging machines. Selecting between disc and drum brakes depends on operational speed, maintenance requirements, and precision needs in industrial applications.

Safety and Reliability Factors

Disc brakes offer superior heat dissipation and consistent stopping power, enhancing safety by reducing brake fade in heavy machinery operations. Drum brakes, while more enclosed and protected from dirt and debris, tend to suffer from heat buildup, which can compromise reliability during prolonged use. The exposed design and faster cooling rate of disc brakes generally result in higher reliability and performance consistency under demanding safety-critical conditions.

Choosing the Right Brake for Your Machinery

Choosing the right brake for your machinery depends on factors such as heat dissipation, maintenance requirements, and braking performance. Disc brakes offer superior heat resistance and consistent stopping power, making them ideal for high-speed or heavy-duty applications. Drum brakes provide a cost-effective solution with effective braking force in low-speed machinery but require more frequent maintenance due to potential heat buildup and wear.

Disc brake vs drum brake (for machinery) Infographic

libmatt.com

libmatt.com