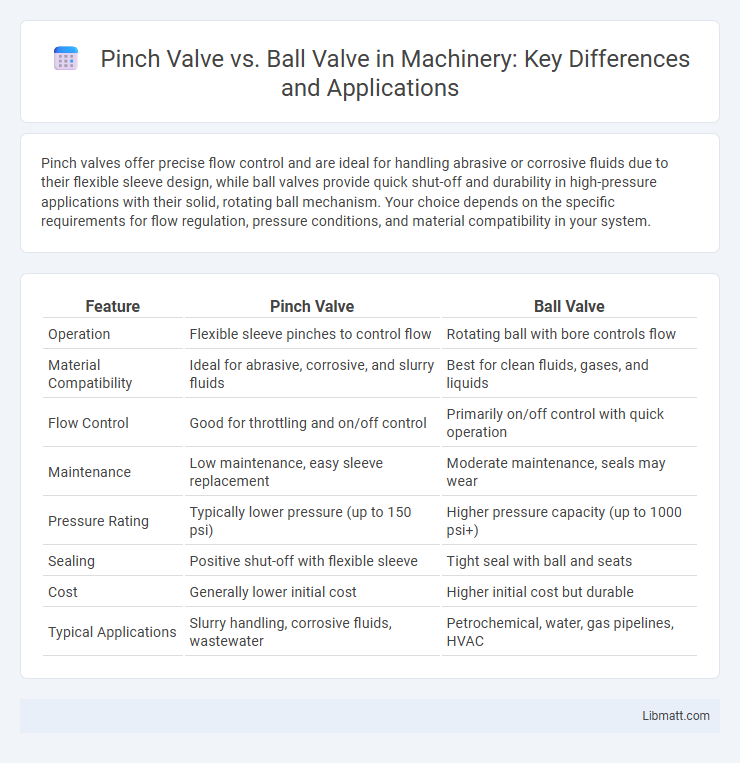

Pinch valves offer precise flow control and are ideal for handling abrasive or corrosive fluids due to their flexible sleeve design, while ball valves provide quick shut-off and durability in high-pressure applications with their solid, rotating ball mechanism. Your choice depends on the specific requirements for flow regulation, pressure conditions, and material compatibility in your system.

Table of Comparison

| Feature | Pinch Valve | Ball Valve |

|---|---|---|

| Operation | Flexible sleeve pinches to control flow | Rotating ball with bore controls flow |

| Material Compatibility | Ideal for abrasive, corrosive, and slurry fluids | Best for clean fluids, gases, and liquids |

| Flow Control | Good for throttling and on/off control | Primarily on/off control with quick operation |

| Maintenance | Low maintenance, easy sleeve replacement | Moderate maintenance, seals may wear |

| Pressure Rating | Typically lower pressure (up to 150 psi) | Higher pressure capacity (up to 1000 psi+) |

| Sealing | Positive shut-off with flexible sleeve | Tight seal with ball and seats |

| Cost | Generally lower initial cost | Higher initial cost but durable |

| Typical Applications | Slurry handling, corrosive fluids, wastewater | Petrochemical, water, gas pipelines, HVAC |

Introduction to Pinch Valves and Ball Valves

Pinch valves control fluid flow by pinching a flexible sleeve, offering excellent resistance to abrasive and corrosive materials, making them ideal for slurry or hazardous media. Ball valves use a rotating spherical ball with a hole to regulate flow, providing tight sealing and rapid shutoff for gases and liquids in high-pressure systems. Your choice between these valves depends on the application's specific requirements for durability, flow control precision, and maintenance needs.

Design and Construction Differences

Pinch valves feature a flexible elastomer sleeve that closes by pinching, ideal for handling abrasive or corrosive fluids without direct metal contact, while ball valves utilize a rotating hollow sphere to control flow, offering tight seals and quick operation. The construction of pinch valves is simpler and involves fewer moving parts, which reduces maintenance needs compared to the durable, metal-based body and internal ball mechanism of ball valves. Your choice depends on the application, with pinch valves better suited for slurry or viscous media and ball valves preferred for precise flow control and high-pressure systems.

How Pinch Valves Work

Pinch valves operate by using a resilient elastomer sleeve that is pinched closed to stop the flow of fluid, creating a tight seal without contact between the valve components and the media. This design allows for unobstructed flow when the sleeve is open, minimizing wear and making them ideal for abrasive or corrosive fluids. In contrast to ball valves, which rely on a rotating ball to control flow, pinch valves provide a gentler and more flexible flow control method suitable for slurries and solids-laden fluids.

How Ball Valves Work

Ball valves control fluid flow using a rotating hollow sphere with a bore, which aligns with the pipe for full flow or turns perpendicular to block flow. The quarter-turn operation provides quick shutoff with minimal pressure drop, making ball valves ideal for applications requiring reliable, tight sealing. You benefit from their durability and ease of maintenance compared to pinch valves, especially in high-pressure or high-temperature systems.

Applications: Pinch Valve vs Ball Valve

Pinch valves excel in handling abrasive, corrosive, or slurries in industries like wastewater treatment, chemical processing, and mining due to their flexible sleeve design that isolates the valve mechanism from the fluid. Ball valves are preferred for applications requiring tight shutoff and high-pressure control in oil and gas, HVAC, and water supply systems because of their durable ball mechanism offering quick and reliable flow regulation. Your choice depends on the medium's characteristics and operational demands, with pinch valves suited for harsh, particulate-laden fluids and ball valves ideal for clean, high-pressure environments.

Advantages of Pinch Valves

Pinch valves offer superior control over fluid flow by providing a tight seal that prevents leaks, making them ideal for handling abrasive or corrosive materials. Their simple design with minimal moving parts reduces maintenance requirements and enhances durability in harsh industrial environments. Pinch valves also enable easy cleaning and sterilization, which is crucial in industries like pharmaceuticals and food processing.

Advantages of Ball Valves

Ball valves offer superior sealing capabilities due to their spherical closure mechanism, ensuring reliable shutoff in high-pressure systems. Their robust construction provides excellent durability and resistance to wear, making them ideal for abrasive or corrosive fluids. Additionally, ball valves enable quick and easy operation with a simple quarter-turn, enhancing efficiency in fluid control applications.

Limitations and Challenges

Pinch valves face limitations with high-pressure applications due to their elastomer sleeve, which can wear out quickly when exposed to abrasive or corrosive materials, reducing longevity. Ball valves encounter challenges in handling slurries or viscous fluids that can cause clogging and increased maintenance requirements. Your choice depends on the specific operational environment, balancing durability against fluid compatibility and pressure demands.

Maintenance and Lifespan Comparison

Pinch valves require minimal maintenance due to their simple design and fewer moving parts, resulting in reduced downtime and lower repair costs. Ball valves, while durable, need regular lubrication and seal replacement to maintain optimal function, especially in high-pressure applications. The lifespan of pinch valves often exceeds that of ball valves in abrasive or corrosive environments, as the elastomer sleeve protects internal components from wear.

Choosing the Right Valve for Your Application

Pinch valves and ball valves serve distinct purposes in fluid control applications, with pinch valves excelling in abrasive or corrosive media due to their elastomer sleeve design, which offers gentle and clog-free operation. Ball valves provide reliable, high-pressure sealing and quick shutoff in clean or moderately contaminated fluids, ideal for precise flow control and isolation. Selecting the right valve depends on factors like fluid type, pressure requirements, maintenance frequency, and application environment to ensure optimal performance and longevity.

Pinch valve vs ball valve Infographic

libmatt.com

libmatt.com