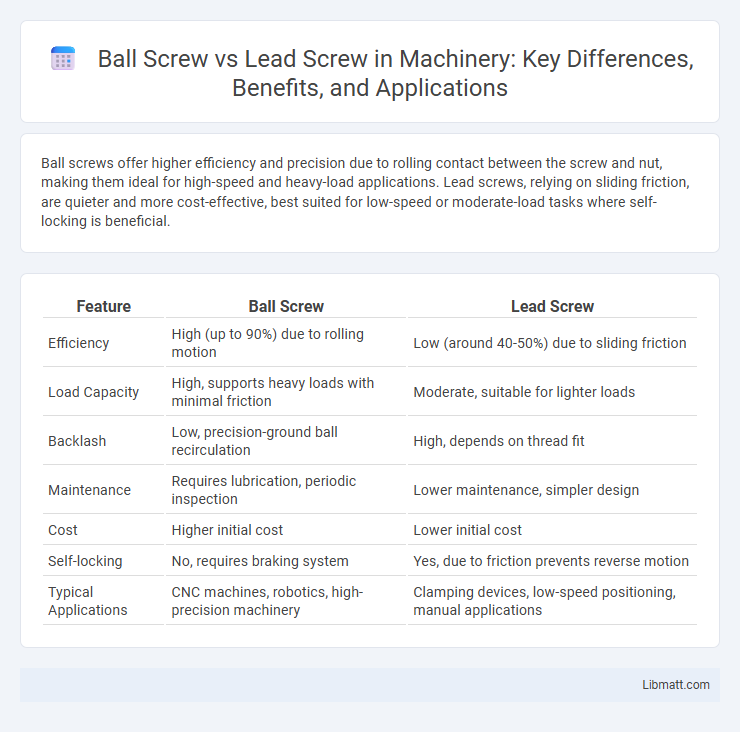

Ball screws offer higher efficiency and precision due to rolling contact between the screw and nut, making them ideal for high-speed and heavy-load applications. Lead screws, relying on sliding friction, are quieter and more cost-effective, best suited for low-speed or moderate-load tasks where self-locking is beneficial.

Table of Comparison

| Feature | Ball Screw | Lead Screw |

|---|---|---|

| Efficiency | High (up to 90%) due to rolling motion | Low (around 40-50%) due to sliding friction |

| Load Capacity | High, supports heavy loads with minimal friction | Moderate, suitable for lighter loads |

| Backlash | Low, precision-ground ball recirculation | High, depends on thread fit |

| Maintenance | Requires lubrication, periodic inspection | Lower maintenance, simpler design |

| Cost | Higher initial cost | Lower initial cost |

| Self-locking | No, requires braking system | Yes, due to friction prevents reverse motion |

| Typical Applications | CNC machines, robotics, high-precision machinery | Clamping devices, low-speed positioning, manual applications |

Introduction to Ball Screws and Lead Screws

Ball screws and lead screws are precision mechanical components used to convert rotational motion into linear motion, commonly found in CNC machines and automation systems. Ball screws offer higher efficiency and reduced friction due to recirculating ball bearings, making them suitable for high-speed, high-accuracy applications. Lead screws, using sliding contact threads, provide simpler, cost-effective solutions with self-locking properties, ideal for lower-speed, heavy-load scenarios where precise positioning is essential for Your projects.

Key Differences Between Ball Screws and Lead Screws

Ball screws use recirculating ball bearings to reduce friction and improve efficiency, while lead screws rely on sliding contact between the screw and nut, resulting in higher friction and lower efficiency. Ball screws provide higher precision, faster speeds, and longer service life, making them ideal for applications requiring accuracy and durability, whereas lead screws are simpler, cost-effective, and suitable for lower load or less precise operations. Your choice depends on factors like load capacity, required speed, accuracy, and budget.

How Ball Screws Work

Ball screws convert rotational motion into linear motion using a threaded shaft and a ball nut containing recirculating ball bearings that minimize friction. These ball bearings roll between the screw shaft and the nut, enabling high efficiency and precise movement with minimal wear. Your machinery benefits from improved accuracy and lower torque requirements compared to lead screws, making ball screws ideal for applications demanding smooth and reliable linear motion.

How Lead Screws Work

Lead screws convert rotational motion into linear motion through their threaded shaft, where the nut travels along the threads as the screw rotates. Your precision in movement is driven by the pitch and thread design, which directly influences the efficiency and load capacity of the lead screw. This mechanism is ideal for applications requiring smooth, controlled motion with moderate speed and high accuracy.

Efficiency Comparison: Ball Screw vs Lead Screw

Ball screws offer higher efficiency, typically between 90% to 95%, compared to lead screws which usually range from 20% to 70% efficiency due to their sliding friction design. The rolling motion in ball screws reduces energy loss and heat generation, making them ideal for high-speed, precision applications. Choosing a ball screw can enhance your system's performance by delivering smoother motion and improved energy efficiency over lead screws.

Precision and Accuracy

Ball screws provide higher precision and accuracy due to their rolling motion, which significantly reduces friction and backlash compared to lead screws. Lead screws, relying on sliding contact, tend to generate more friction and wear, resulting in lower positional accuracy over time. You should choose ball screws for applications demanding tight tolerances and consistent repeatability.

Load Capacity and Durability

Ball screws offer higher load capacity due to their rolling element design, which reduces friction and wear compared to lead screws that rely on sliding contact. The hardened steel balls in ball screws enable smoother motion and greater durability under heavy loads and continuous operation. Lead screws, while simpler and more cost-effective, experience faster wear and lower load tolerance, making them less suitable for high-precision, high-load applications.

Maintenance Requirements

Ball screws require less frequent maintenance due to their recirculating ball bearings, which reduce friction and wear, making them ideal for high-precision applications. Lead screws demand more regular lubrication and inspection because their sliding motion causes higher friction and potential debris buildup, impacting long-term performance. Proper maintenance of your chosen screw type ensures optimal efficiency and prolongs the lifespan of mechanical systems.

Cost Analysis and Application Suitability

Ball screws generally cost more than lead screws due to their precision engineering and advanced materials, making them ideal for high-accuracy and high-load applications such as CNC machinery. Lead screws offer a more affordable solution for lower-speed, lighter-load uses like 3D printers and manual positioning systems, where efficiency and precision demands are less critical. Evaluating your project's budget and performance requirements will help determine the most cost-effective and suitable screw type for your application.

Choosing the Right Screw for Your Project

Ball screws offer higher efficiency and precision, making them ideal for applications requiring fast, smooth motion and long service life. Lead screws are simpler, cost-effective, and provide better holding torque with less back-driving, suited for slower, low-load tasks. Your choice depends on the need for speed, accuracy, load capacity, and budget constraints in your project.

Ball screw vs lead screw Infographic

libmatt.com

libmatt.com