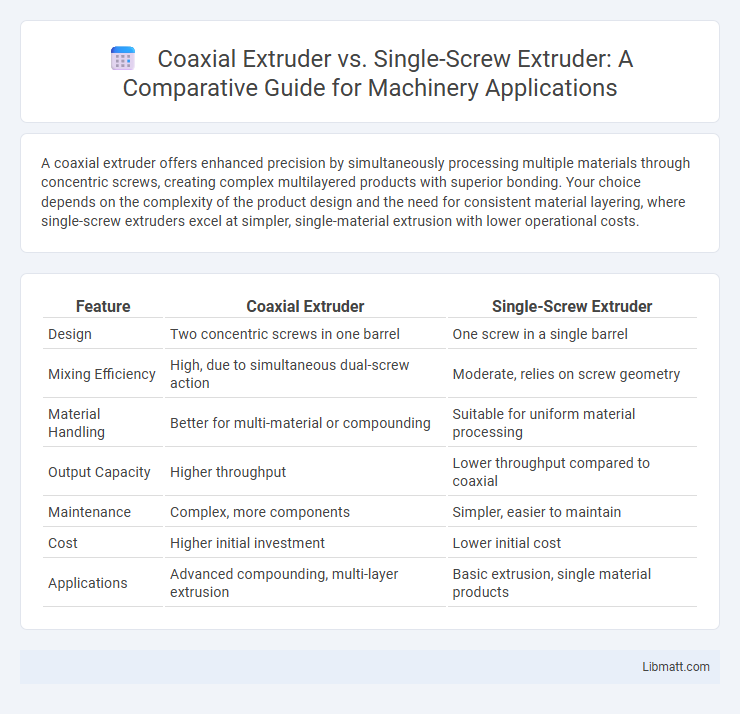

A coaxial extruder offers enhanced precision by simultaneously processing multiple materials through concentric screws, creating complex multilayered products with superior bonding. Your choice depends on the complexity of the product design and the need for consistent material layering, where single-screw extruders excel at simpler, single-material extrusion with lower operational costs.

Table of Comparison

| Feature | Coaxial Extruder | Single-Screw Extruder |

|---|---|---|

| Design | Two concentric screws in one barrel | One screw in a single barrel |

| Mixing Efficiency | High, due to simultaneous dual-screw action | Moderate, relies on screw geometry |

| Material Handling | Better for multi-material or compounding | Suitable for uniform material processing |

| Output Capacity | Higher throughput | Lower throughput compared to coaxial |

| Maintenance | Complex, more components | Simpler, easier to maintain |

| Cost | Higher initial investment | Lower initial cost |

| Applications | Advanced compounding, multi-layer extrusion | Basic extrusion, single material products |

Introduction to Extrusion Technologies

Coaxial extruders feature a concentric screw design allowing for precise multilayer processing, making them ideal for complex material blending and advanced applications. Single-screw extruders, known for their simplicity and versatility, handle a broad range of thermoplastics with consistent melting and mixing performance. Understanding the capabilities of both extrusion technologies helps optimize your production process and material quality.

What is a Single-Screw Extruder?

A single-screw extruder is a widely used machine in plastic processing that consists of a single rotating screw within a heated barrel to melt, mix, and convey raw material. It operates by pushing the polymer material through a die to form continuous shapes, making it essential for producing pipes, sheets, and films. This type of extruder is valued for its simplicity, reliability, and cost-effectiveness in handling thermoplastics.

Understanding Coaxial Extruders

Coaxial extruders feature two concentric screws, allowing simultaneous processing of multiple materials or enhancing mixing efficiency compared to single-screw extruders that rely on one screw for melting and conveying. Your production benefits from improved material homogeneity and the ability to create complex multilayer structures using coaxial technology, which single-screw extruders cannot achieve as effectively. Understanding coaxial extruders helps optimize processes in applications like multilayer film extrusion, enhancing product quality and performance.

Core Design Differences

Coaxial extruders feature a dual-barrel configuration that allows simultaneous processing of multiple materials, enabling the creation of complex multi-layered products with precise core-to-skin ratio control. In contrast, single-screw extruders utilize a single rotating screw within a barrel, primarily designed for homogeneous material mixing and consistent melt flow. Understanding these core design differences helps you select the right extruder based on desired product complexity and material compatibility.

Material Compatibility and Processing

Coaxial extruders offer enhanced material compatibility by enabling simultaneous processing of multiple polymers or composites, leading to better interfacial bonding and customized material properties. Single-screw extruders excel in processing homogeneous thermoplastics, providing efficient melting and consistent flow for standard polymer formulations. The choice between the two depends on the desired material complexity and specific processing requirements for optimal product performance.

Output Quality: Precision and Consistency

Coaxial extruders deliver superior output quality characterized by enhanced precision and consistency due to their dual-screw design, which ensures uniform material mixing and temperature control. Single-screw extruders often face challenges with shear variation and less uniform melting, resulting in occasional product inconsistencies and dimensional deviations. For industries requiring high precision, such as medical tubing or wire insulation, coaxial extruders provide more reliable and consistent extrusion results.

Energy Efficiency Comparison

Coaxial extruders exhibit higher energy efficiency than single-screw extruders due to their enhanced mixing capabilities and reduced mechanical shear, which lower power consumption during processing. Studies show coaxial extruders can decrease energy usage by up to 20% in polymer compounding applications compared to conventional single-screw designs. Optimized screw geometry and improved heat transfer in coaxial systems contribute significantly to these energy savings.

Maintenance and Operational Costs

Coaxial extruders generally incur higher maintenance and operational costs compared to single-screw extruders due to their complex design and multiple moving parts requiring specialized servicing. Single-screw extruders offer lower maintenance demands and reduced operational expenses, making them more cost-effective for standard applications. Your choice will impact long-term expenses, with coaxial units better suited for intricate processes despite increased upkeep.

Application Areas and Industry Use Cases

Coaxial extruders are widely used in the production of multilayer films, medical tubing, and specialty cables, offering superior precision in layering and material compatibility for industries such as healthcare and electronics. Single-screw extruders dominate in the processing of bulk plastics like pellets and powders, commonly applied in packaging, automotive parts, and construction materials due to their efficiency and versatility. The choice between coaxial and single-screw extrusion hinges on product complexity and specific industry requirements, particularly where multilayer structures or high-volume output are critical factors.

Choosing the Right Extruder for Your Needs

Choosing the right extruder depends on the specific application and material requirements, with coaxial extruders offering precise multi-layer extrusion for complex products like medical tubing or wire coatings. Single-screw extruders are ideal for general-purpose applications, efficiently processing a wide range of thermoplastics with simpler operation and lower maintenance costs. Your decision should weigh factors like product complexity, material compatibility, and production volume to optimize performance and cost-effectiveness.

Coaxial extruder vs single-screw extruder Infographic

libmatt.com

libmatt.com