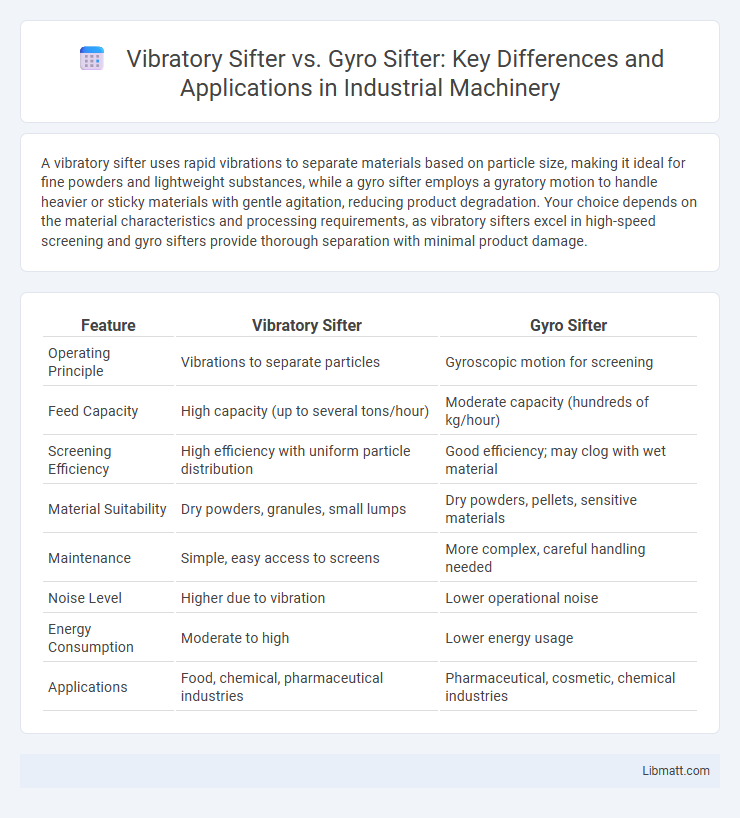

A vibratory sifter uses rapid vibrations to separate materials based on particle size, making it ideal for fine powders and lightweight substances, while a gyro sifter employs a gyratory motion to handle heavier or sticky materials with gentle agitation, reducing product degradation. Your choice depends on the material characteristics and processing requirements, as vibratory sifters excel in high-speed screening and gyro sifters provide thorough separation with minimal product damage.

Table of Comparison

| Feature | Vibratory Sifter | Gyro Sifter |

|---|---|---|

| Operating Principle | Vibrations to separate particles | Gyroscopic motion for screening |

| Feed Capacity | High capacity (up to several tons/hour) | Moderate capacity (hundreds of kg/hour) |

| Screening Efficiency | High efficiency with uniform particle distribution | Good efficiency; may clog with wet material |

| Material Suitability | Dry powders, granules, small lumps | Dry powders, pellets, sensitive materials |

| Maintenance | Simple, easy access to screens | More complex, careful handling needed |

| Noise Level | Higher due to vibration | Lower operational noise |

| Energy Consumption | Moderate to high | Lower energy usage |

| Applications | Food, chemical, pharmaceutical industries | Pharmaceutical, cosmetic, chemical industries |

Introduction: Understanding Vibratory and Gyro Sifters

Vibratory sifters employ high-frequency vibration to separate particles by size, offering efficient screening for a wide range of materials. Gyro sifters use a unique gyratory motion, providing gentle yet thorough separation ideal for delicate or sticky substances. Your choice between vibratory and gyro sifters depends on the material properties and desired screening precision.

Working Principles of Vibratory Sifters

Vibratory sifters operate by using rapid, linear vibrations to separate particles through a mesh screen, ensuring efficient material classification based on size. The vibration causes particles to move across and through the screen, minimizing clogging and enhancing throughput for fine and coarse materials alike. Your choice of a vibratory sifter provides consistent particle separation suitable for food, pharmaceutical, and chemical industries requiring high accuracy.

Working Mechanism of Gyro Sifters

Gyro sifters operate using a centrifugal force generated by a circular motion inside the sifting chamber, causing materials to move in a spiral path across the screen. This mechanism enhances the separation efficiency by ensuring finer particles pass through the mesh while larger particles are expelled along the outer edge. Understanding the working mechanism of gyro sifters can help you optimize your material separation process for improved productivity.

Key Differences Between Vibratory and Gyro Sifters

Vibratory sifters use linear vibration to separate particles, ensuring precise particle size control and consistent throughput, while gyro sifters employ a circular motion that gently handles delicate materials, making them ideal for fragile or sticky substances. You will notice vibratory sifters are better suited for high-capacity applications with robust materials, whereas gyro sifters excel in low-capacity, fine mesh screening with minimum product degradation. Efficiency, capacity, and material handling requirements are the primary factors guiding the choice between vibratory and gyro sifting technology.

Comparative Efficiency and Performance

Vibratory sifters deliver high screening capacity with consistent particle separation through rapid vertical motion, ideal for handling dry powders and fine materials. Gyro sifters employ a gentle gyratory motion, reducing product degradation and ensuring more precise separation of delicate or sticky substances. Your choice depends on the material type and throughput needs, with vibratory sifters suited for high-speed operations and gyro sifters excelling in applications requiring careful material handling.

Applications and Industries Served

Vibratory sifters excel in handling fine powders and granules, making them ideal for pharmaceutical, food processing, and chemical industries where precise particle separation is critical. Gyro sifters are preferred in bulk material handling applications such as agriculture, plastics, and minerals due to their robust design and ability to process large volumes efficiently. Both sifters serve diverse industries, but vibratory sifters are favored for gentle, high-accuracy screening, while gyro sifters are chosen for heavy-duty, high-capacity screening tasks.

Advantages of Vibratory Sifters

Vibratory sifters offer precise particle separation with minimal noise and lower maintenance costs compared to gyro sifters. Their efficient linear vibration mechanism ensures faster processing speeds and better handling of fine powders, enhancing product quality. You benefit from improved scalability and ease of integration into automated production lines, making vibratory sifters ideal for high-throughput applications.

Benefits of Gyro Sifters

Gyro sifters offer superior screening efficiency and gentle material handling compared to vibratory sifters, reducing product degradation and increasing yield. Their compact design and low noise operation enhance workspace ergonomics and safety. With adjustable rotary speeds and modular screens, gyro sifters provide versatile solutions for fine, coarse, and mixed material separation in pharmaceutical, food, and chemical industries.

Maintenance and Operational Costs

Vibratory sifters typically require more frequent maintenance due to their numerous moving parts and motorized vibration mechanism, leading to higher operational costs over time. Gyro sifters feature a simpler design with fewer mechanical components, resulting in reduced wear and tear and lower maintenance expenses. The energy consumption is generally lower in gyro sifters, contributing to cost savings during prolonged use compared to vibratory sifters.

Choosing the Right Sifter for Your Process

Selecting the right sifter for your process depends on factors such as material type, particle size, and production volume. Vibratory sifters excel in handling fine powders with high screening efficiency and reduced noise levels, while gyro sifters offer gentle screening suitable for fragile or irregular particles. Evaluating operational requirements and maintenance preferences ensures optimal performance and product quality in your application.

Vibratory sifter vs gyro sifter Infographic

libmatt.com

libmatt.com